Device for monitoring micro-particles shapes and dispersion based on image

A technology of image monitoring and micro-particles, applied in the field of optics, can solve problems such as large amount of calculation, time-consuming, difficult to develop, etc., and achieve the effect of improving the sensitivity of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

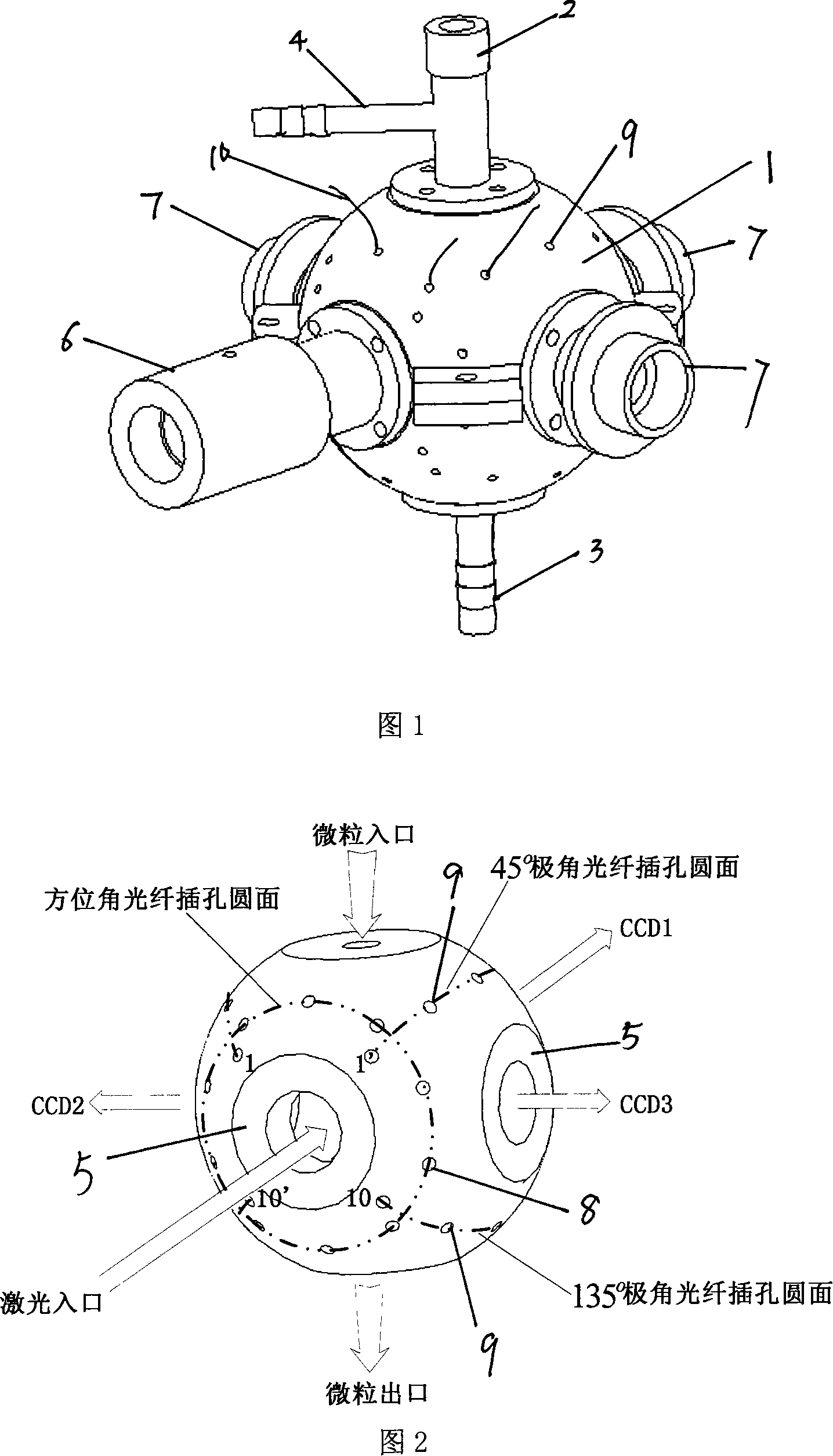

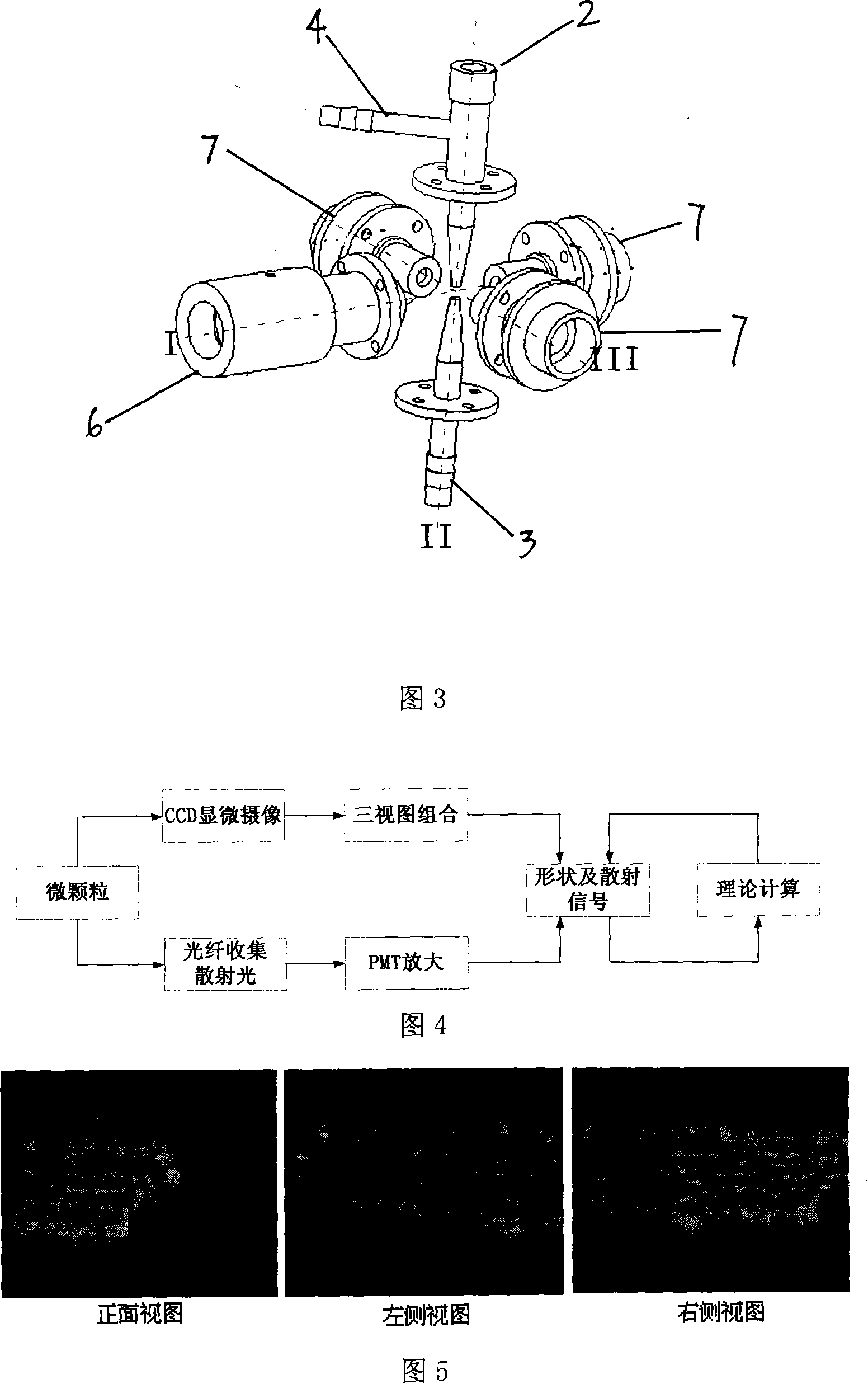

[0027] See attached picture.

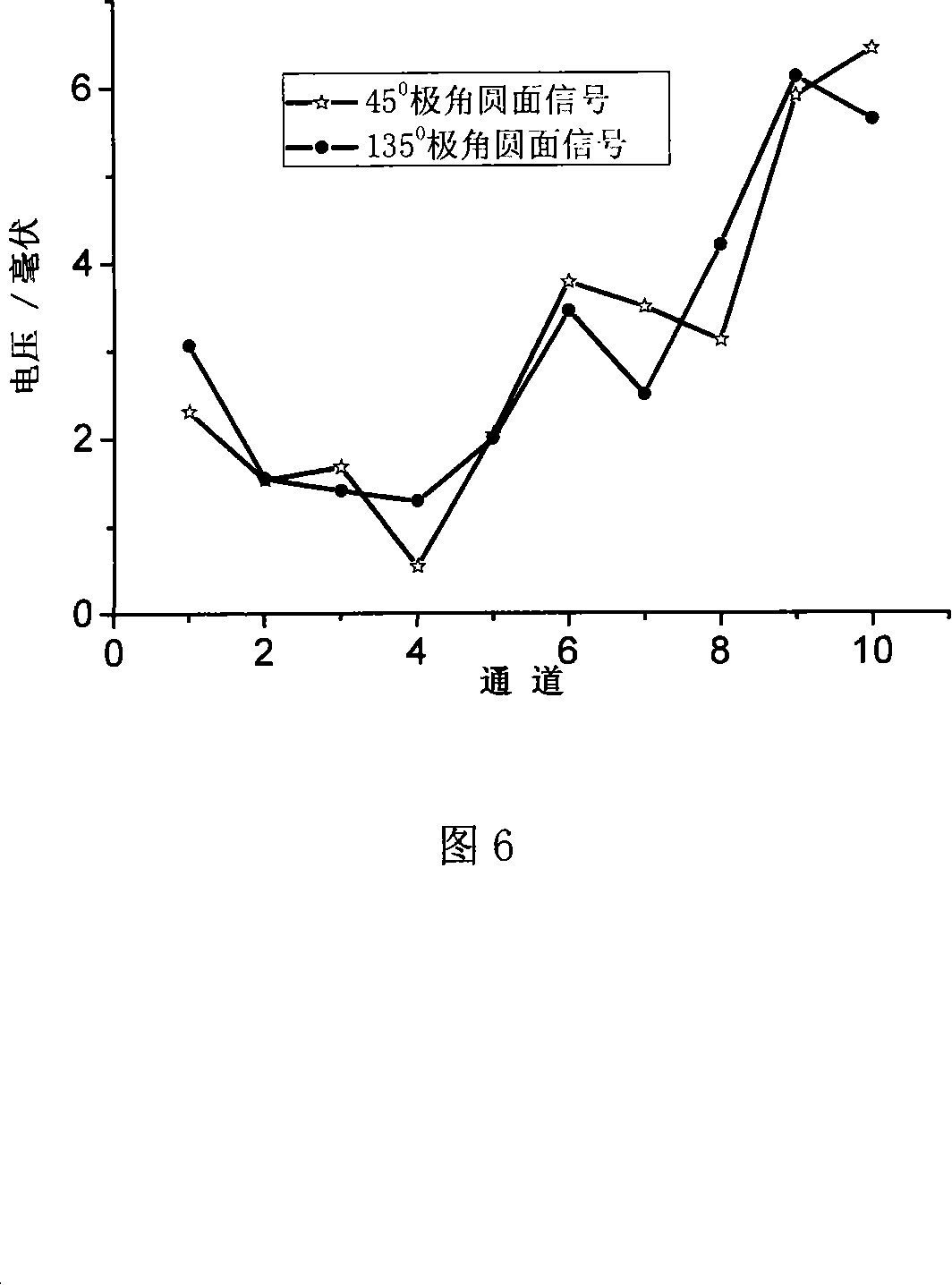

[0028] The device for monitoring the shape and scattering of microparticles based on images is characterized in that it includes a spherical scattering cavity 1, the inner surface of which is roughened and blackened, and the top and bottom of the scattering cavity 1 are respectively positioned on the radial line. The sample tube 2 and the outlet tube 3, the microparticle flow incident from the sample tube 2 passes through the cavity center and then enters the outlet tube 3, and the side wall of the sample tube 2 is communicated with a sheath flow tube 4, which is connected with the sample tube 2. On the radial surface of the scattering chamber 1 perpendicular to the central axis of the air outlet pipe 3, there are four installation holes 5 evenly arranged, and each installation hole 5 points to the center of the scattering chamber 1, and one of the installation holes 5 is installed with Semiconductor laser 6, microscope magnifying CCD imaging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com