Calibrating apparatus of integral type vehicle mounted digital display type vehicle fourth wheel orientator

A four-wheel aligner and verification device technology, applied in wheel testing and other directions, can solve the problems of large cumulative error, complex manufacturing, complex structure, etc., and achieve the effects of reducing equipment weight, reducing frictional resistance, and convenient data reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

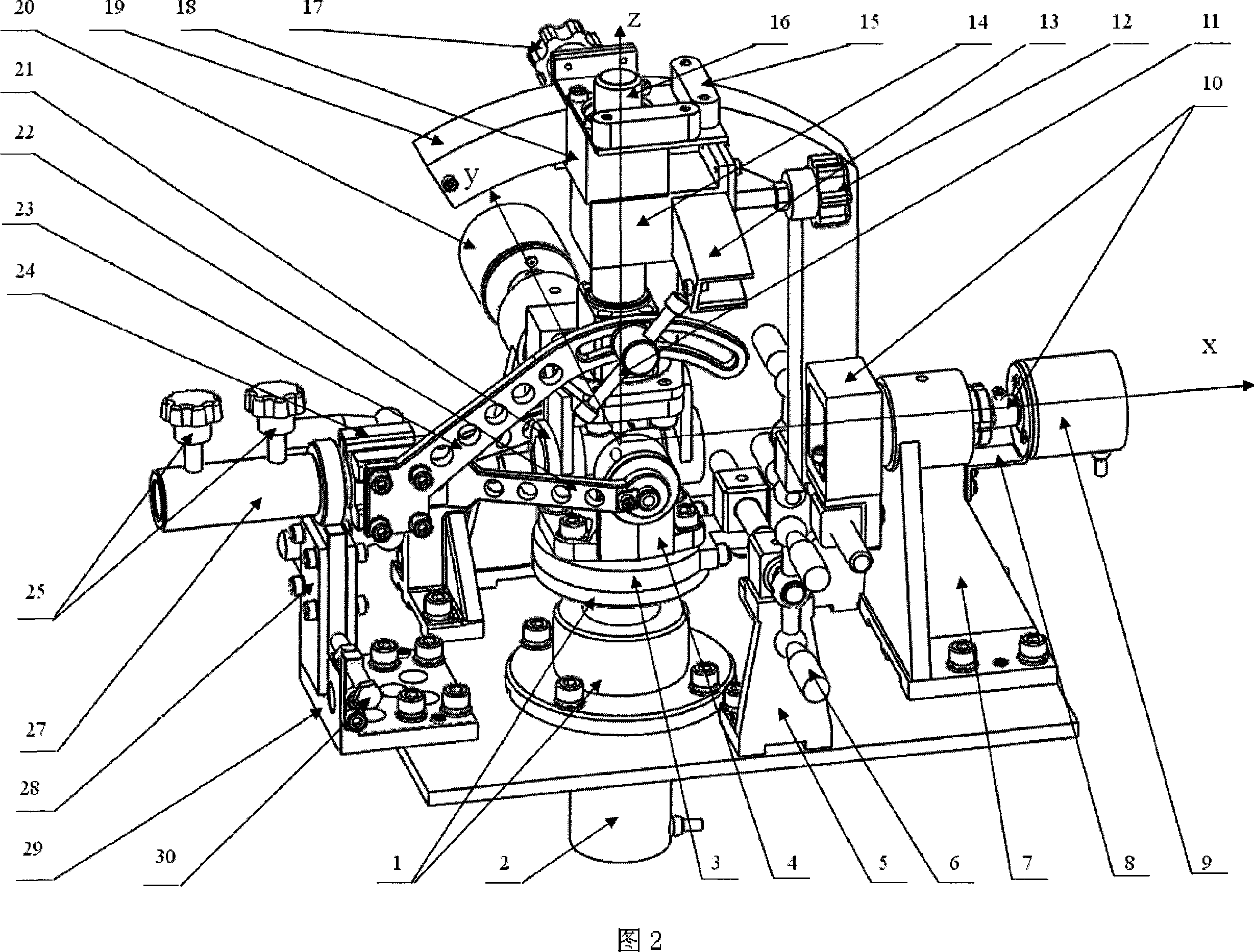

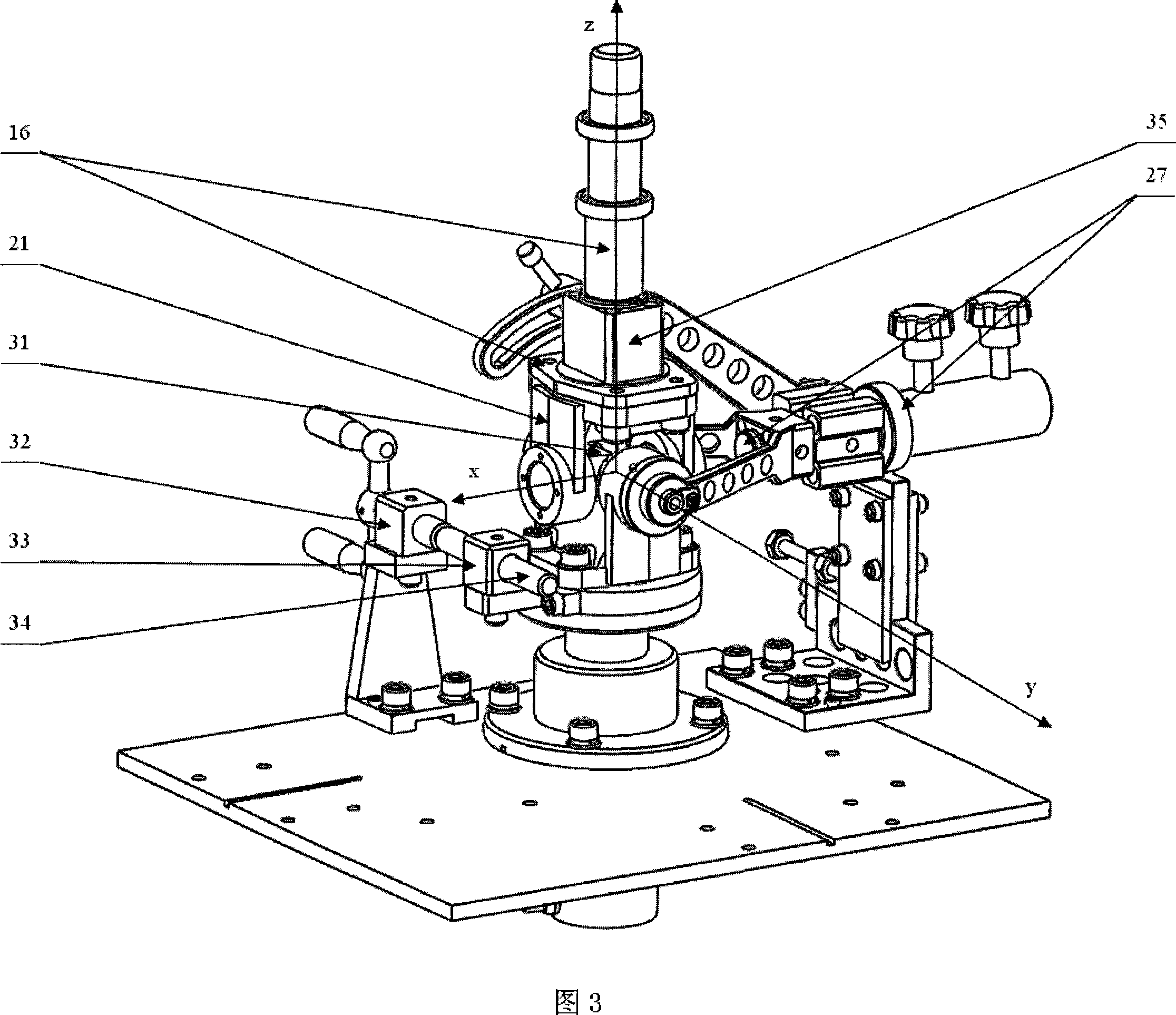

[0077] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

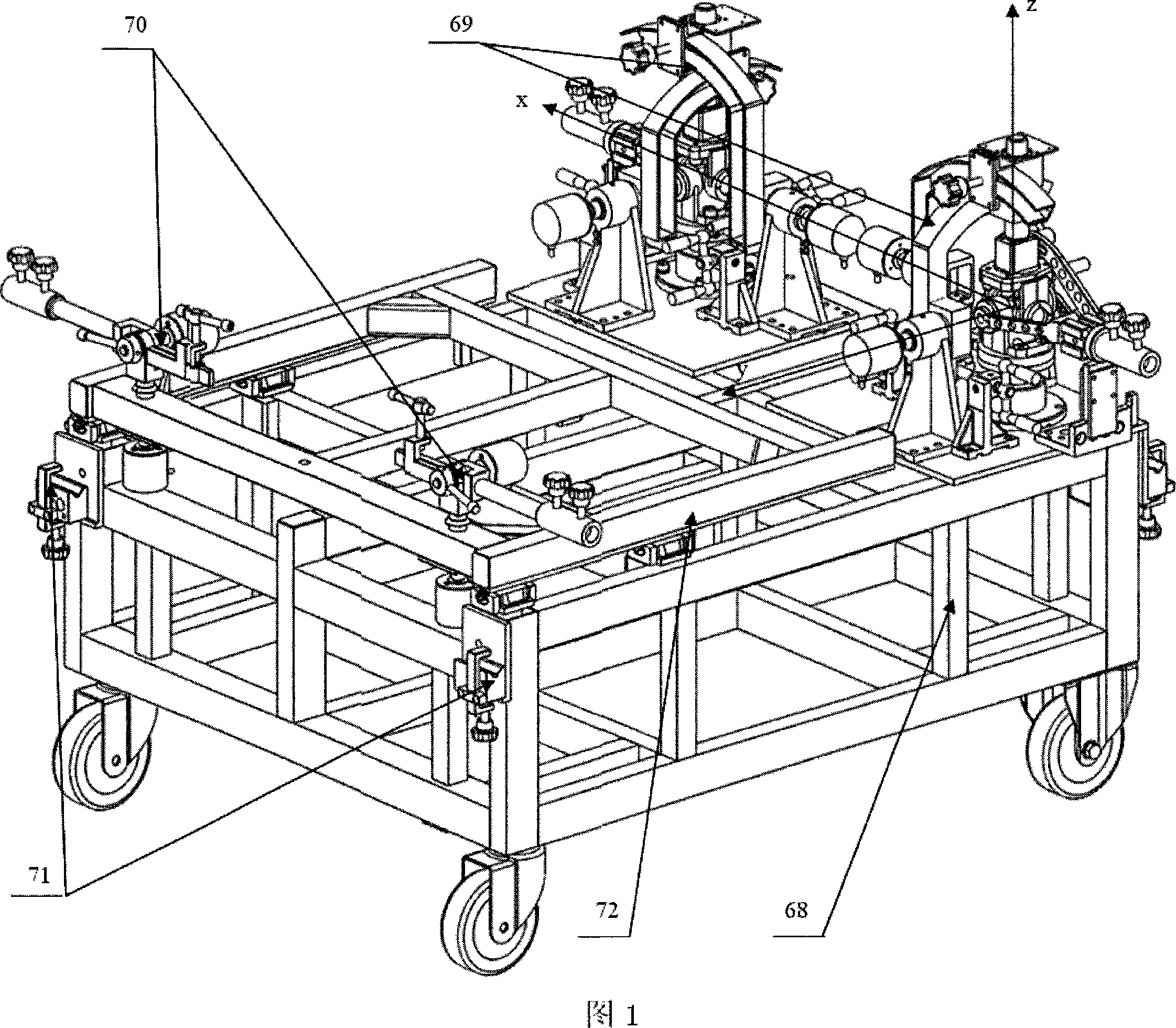

[0078] Referring to Fig. 1 to Fig. 12, the present invention adopts an integral frame, which is different from the split frame used in the prior art, and greatly changes the structure and main parts of the verification device. The verification device of the integral vehicle-mounted digital display four-wheel aligner is composed of a frame 68, a wheelbase adjustment part 72, a rear wheel inspection part 70, a front wheel inspection part 69 and a zero point inspection part 71.

[0079] Frame 68 is integral, and this is the biggest difference with prior art, and he can be welded the frame type structural part of cuboid with section steel and steel plate. It is the basic component of the verification device of the integral vehicle-mounted digital display four-wheel aligner, and is installed directly on the ground horizontally.

[0080] It is also possible to install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com