Textile machine having doffing device

A doffing and fiber technology, applied in the field of fiber machinery, can solve the problems of time increase, control mechanism cost increase, low doffing operation efficiency, etc., and achieve the effects of preventing low work efficiency, simplifying device structure, and preventing burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described below with reference to the drawings.

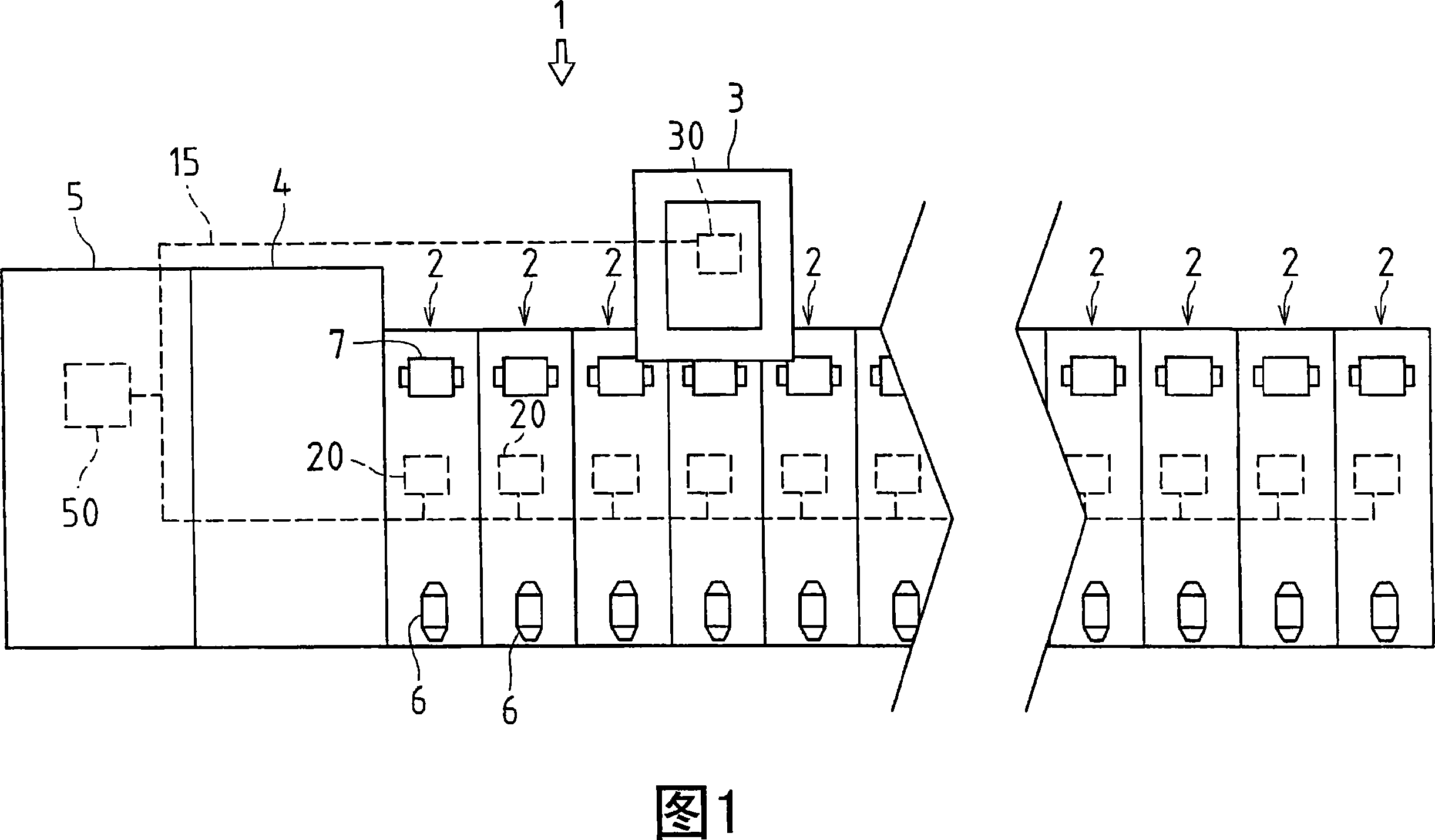

[0035] Next, a winder 1 according to an embodiment of the present invention will be described with reference to FIG. 1 .

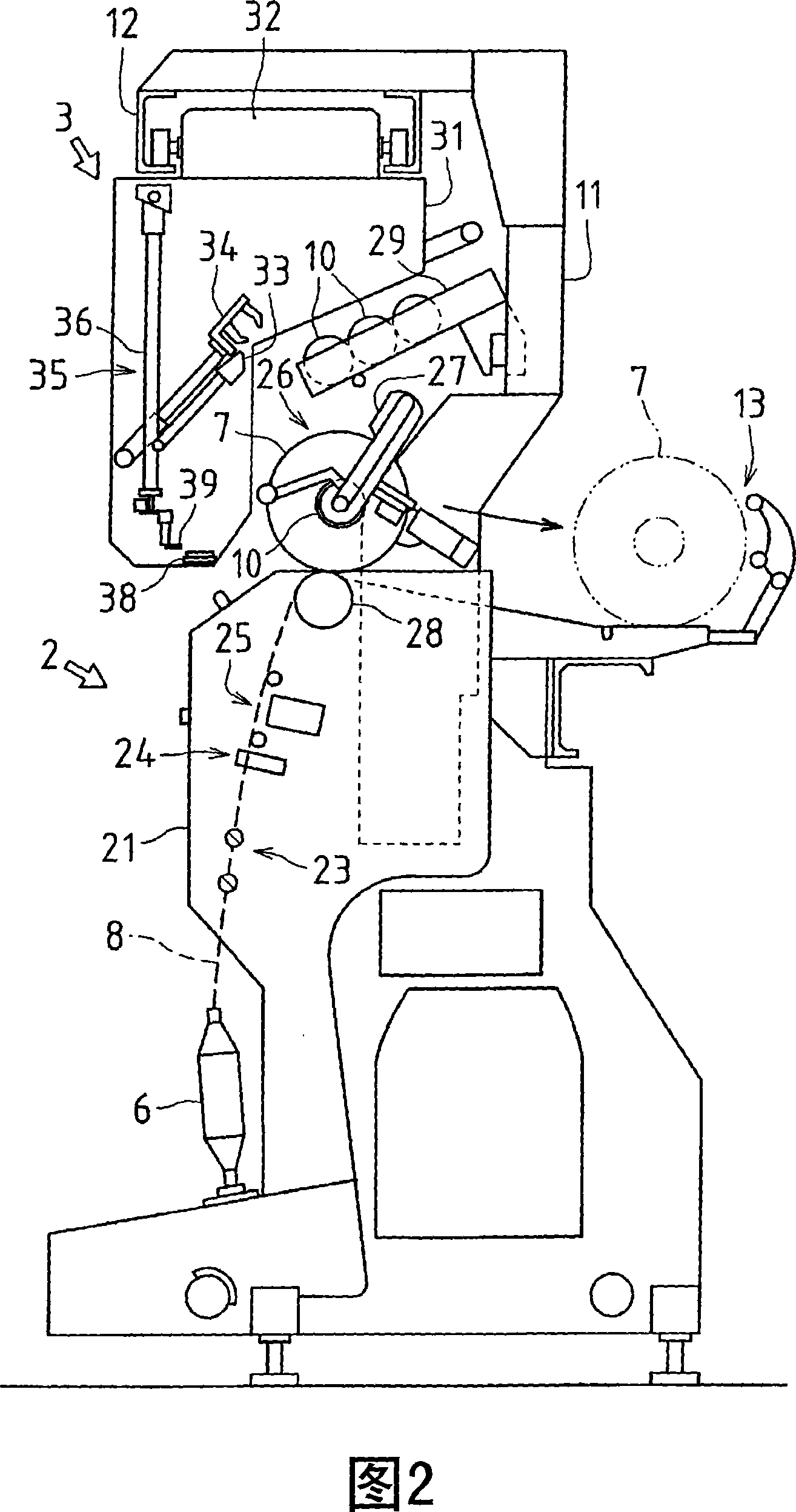

[0036] The winder 1 is a device that unwinds a yarn supplying bobbin 6 that is a package of raw material yarn to form a package 7 .

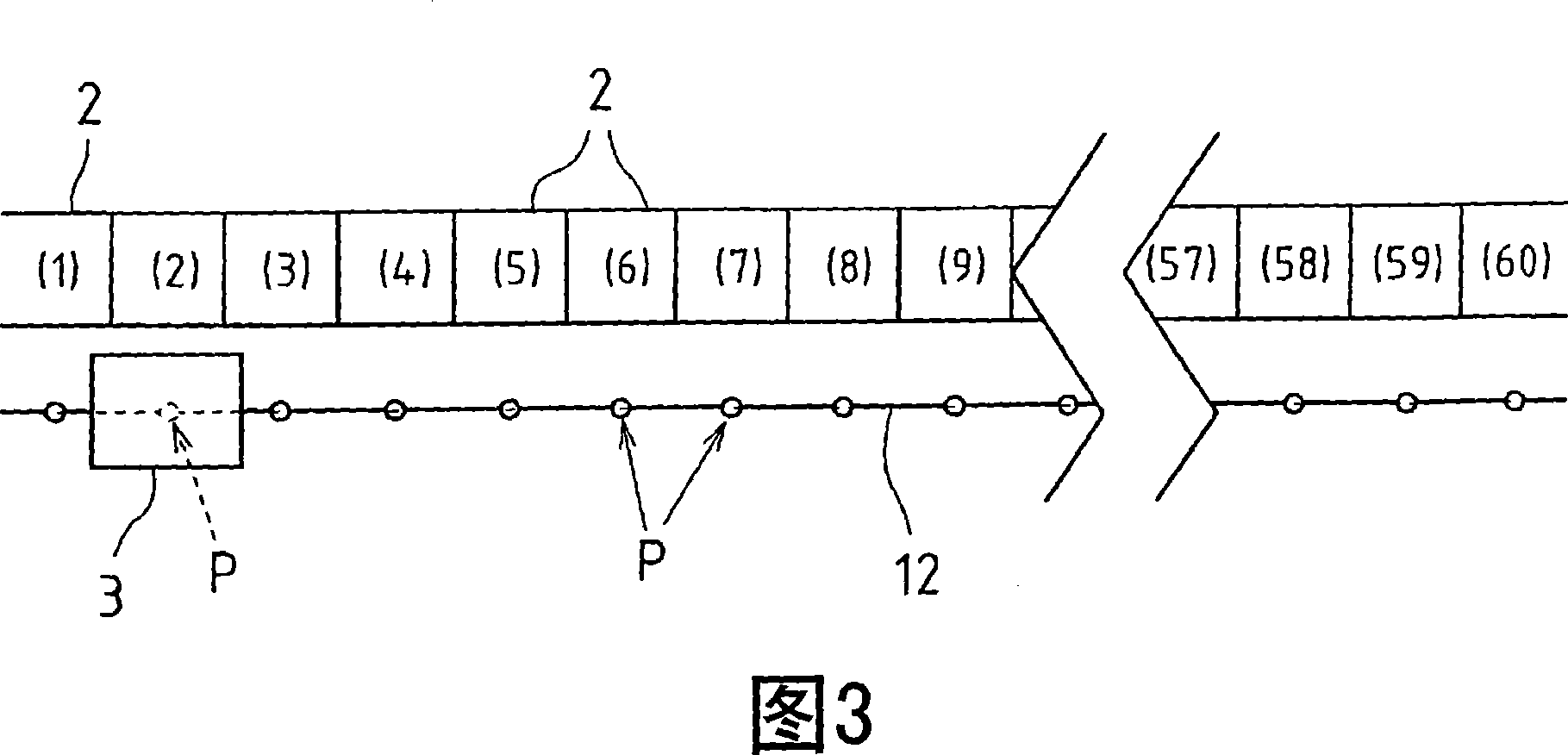

[0037] This winder 1 has a plurality of winding units 2 arranged side by side in one direction, a doffing device 3 freely movable along the row of winding units 2 , and an air supply unit 4 arranged at one end side of the row of winding units 2 . And the main body control part 5.

[0038] Here, the winding unit 2 refers to a unit (assembly of devices) for forming one package 7 on one winding drum 10 . The winder 1 can form packages 7 in parallel corresponding to the number of winding units 2 arranged in the winder 1 .

[0039] In addition, the doffing device 3 is a device that moves to any of the above-mentioned winding u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com