Mud scraper

A mud scraper and scraper technology, applied in the direction of the settlement tank, etc., can solve the problems of long maintenance time, inconvenient maintenance and replacement, high cost, etc., and achieve the effect of good effect, reduced workload and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

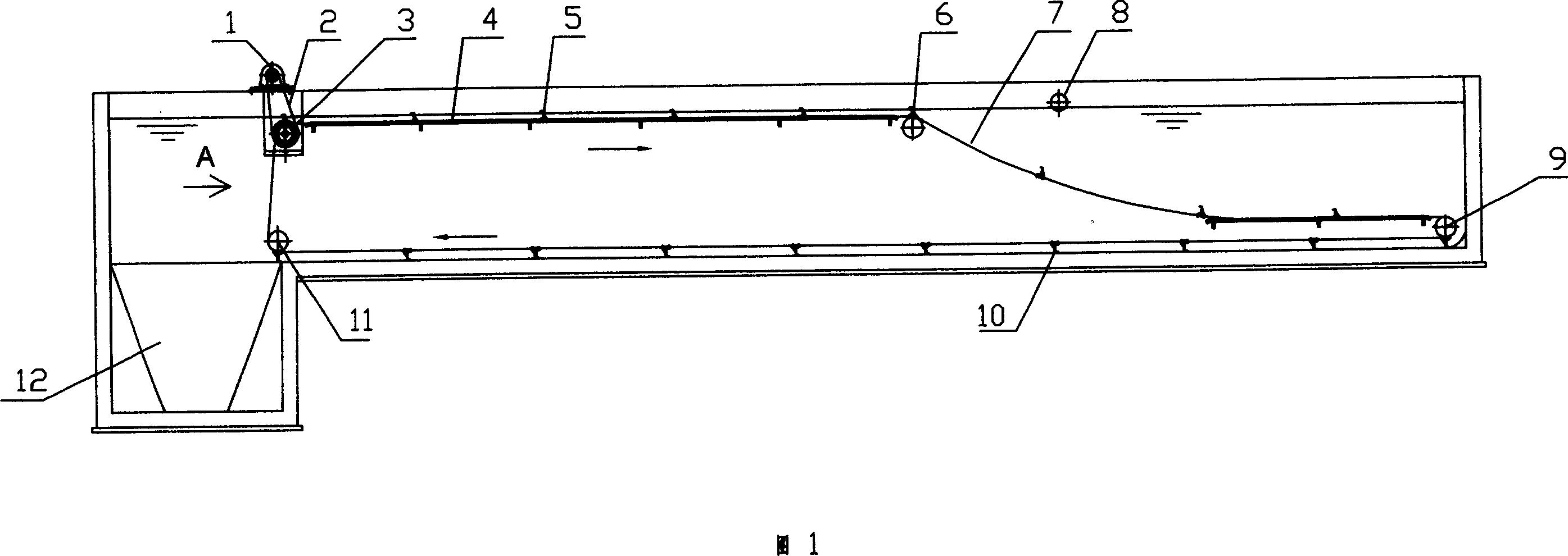

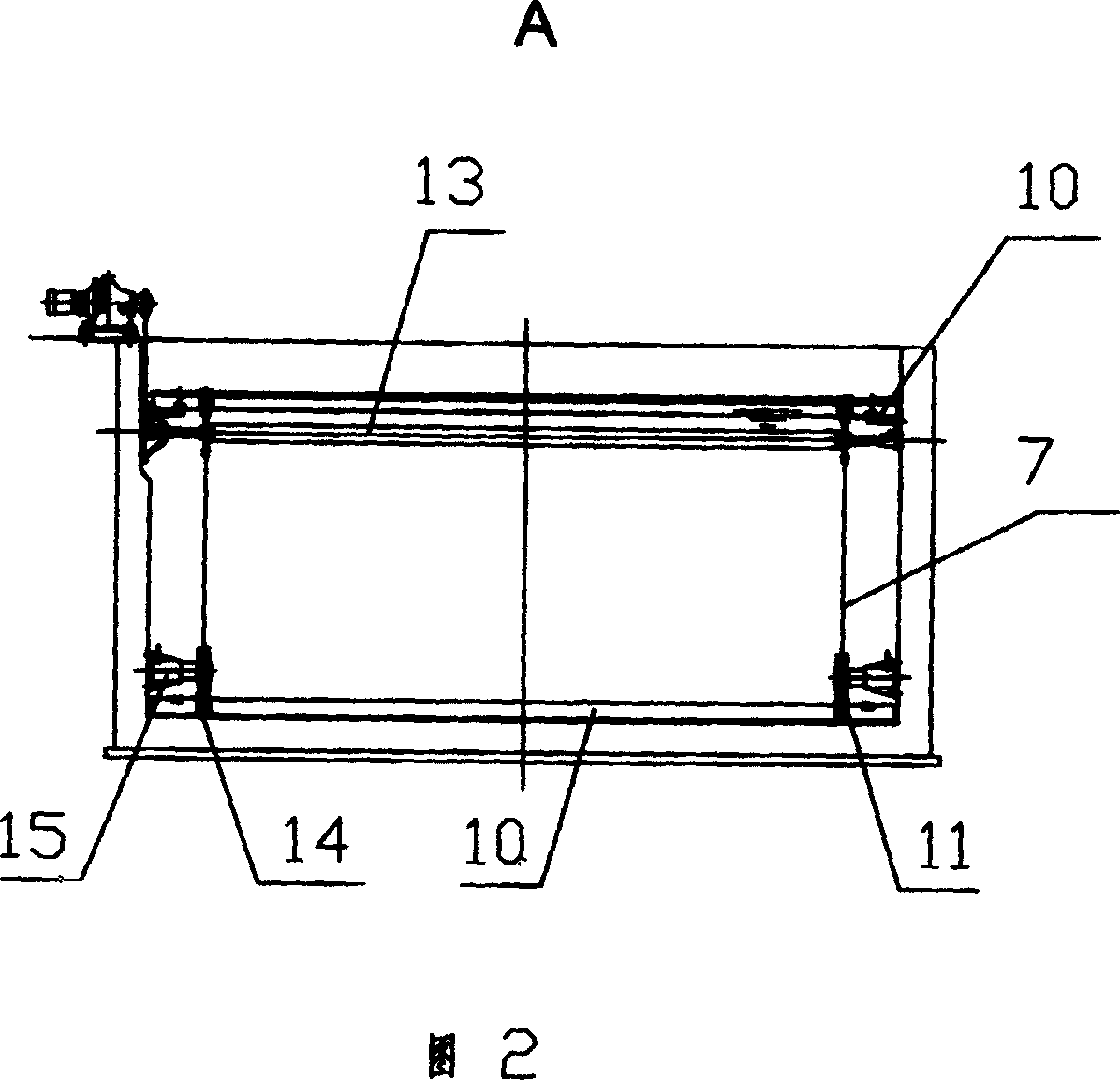

[0019] According to the pool width, the width of the mud scraper of the present invention is set, and the length of the transmission shaft 13 and the scraper 10 is determined as required; a mud bucket is arranged at the end of the pool, and the upper opening of the mud bucket corresponds to the mud scraper mud discharge position; the mud scraper When the scraper 10 reaches the upper stroke, its height corresponds to the height of the liquid level in the pool, so that it can skim off the scum on the liquid level.

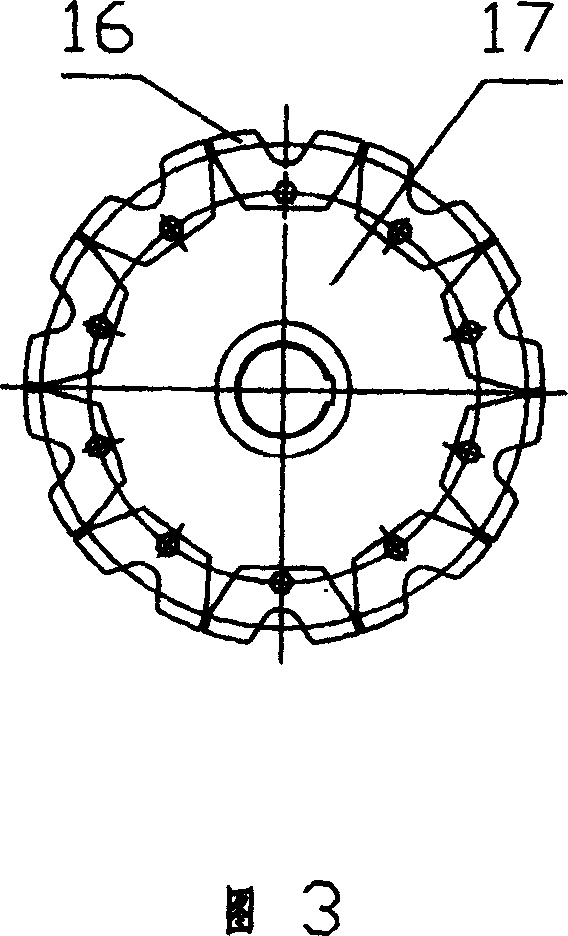

[0020] The driving motor 1 is set above the liquid level, and the sprocket 3 and the upper guide wheel 6 are set near the liquid level, and the driving motor 1 and the sprocket 3 are connected by the driving chain 2; at the bottom of the pool, the guiding wheel 9 and the guiding wheel 11 are set , the sprocket 3, the guide wheel 6, the guide wheel 9, and the guide wheel 11 are connected by a chain 7, wherein the guide wheel 9 is adjustable, and the tightness of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com