Automatic releasing mechanism of coffe bag for coffe maker

A technology for automatic shedding and coffee pods, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of not giving the mechanical structure of the driving block, complex structure, etc., and achieve convenient assembly, simple shedding process, and simple component structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

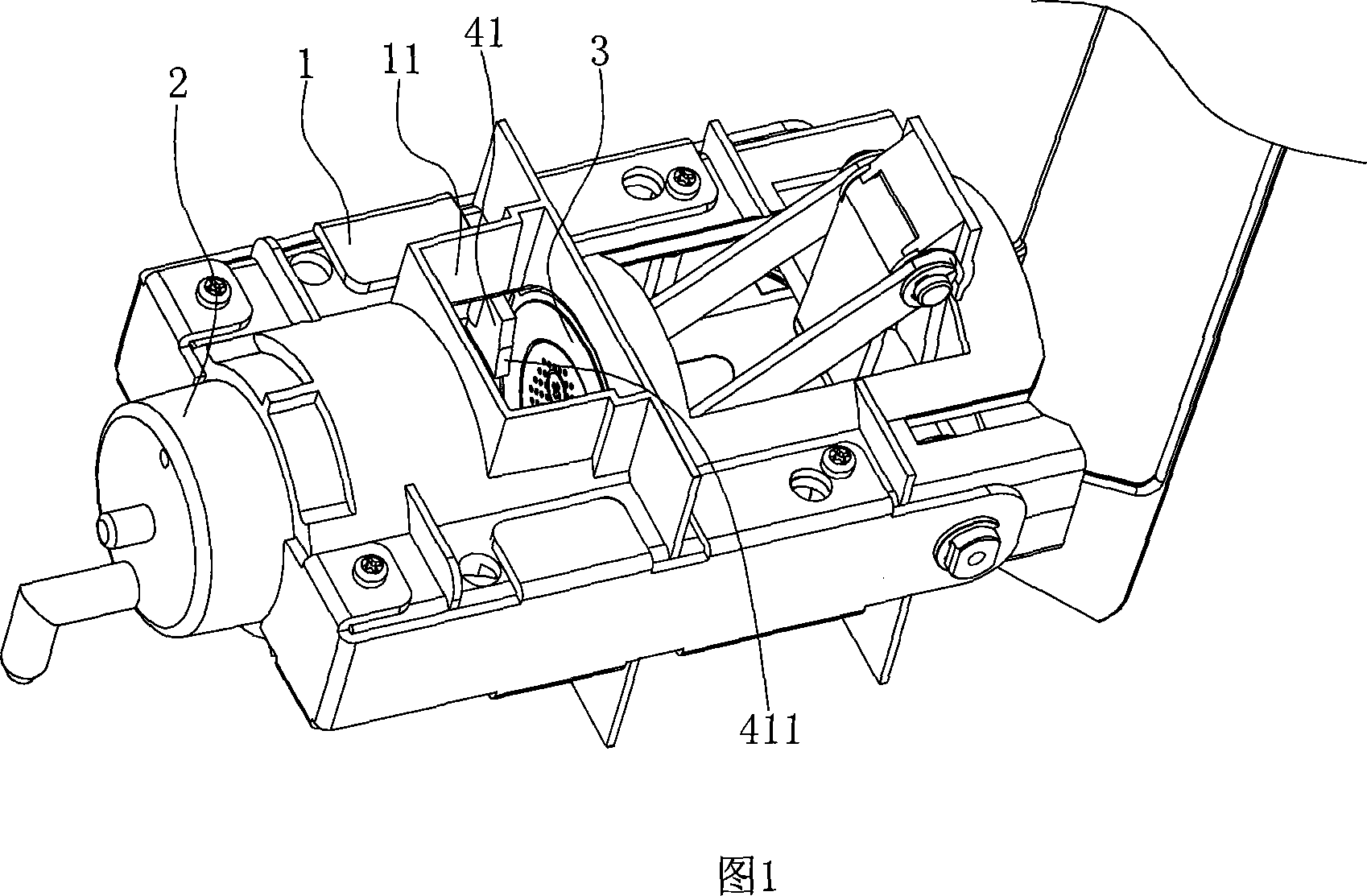

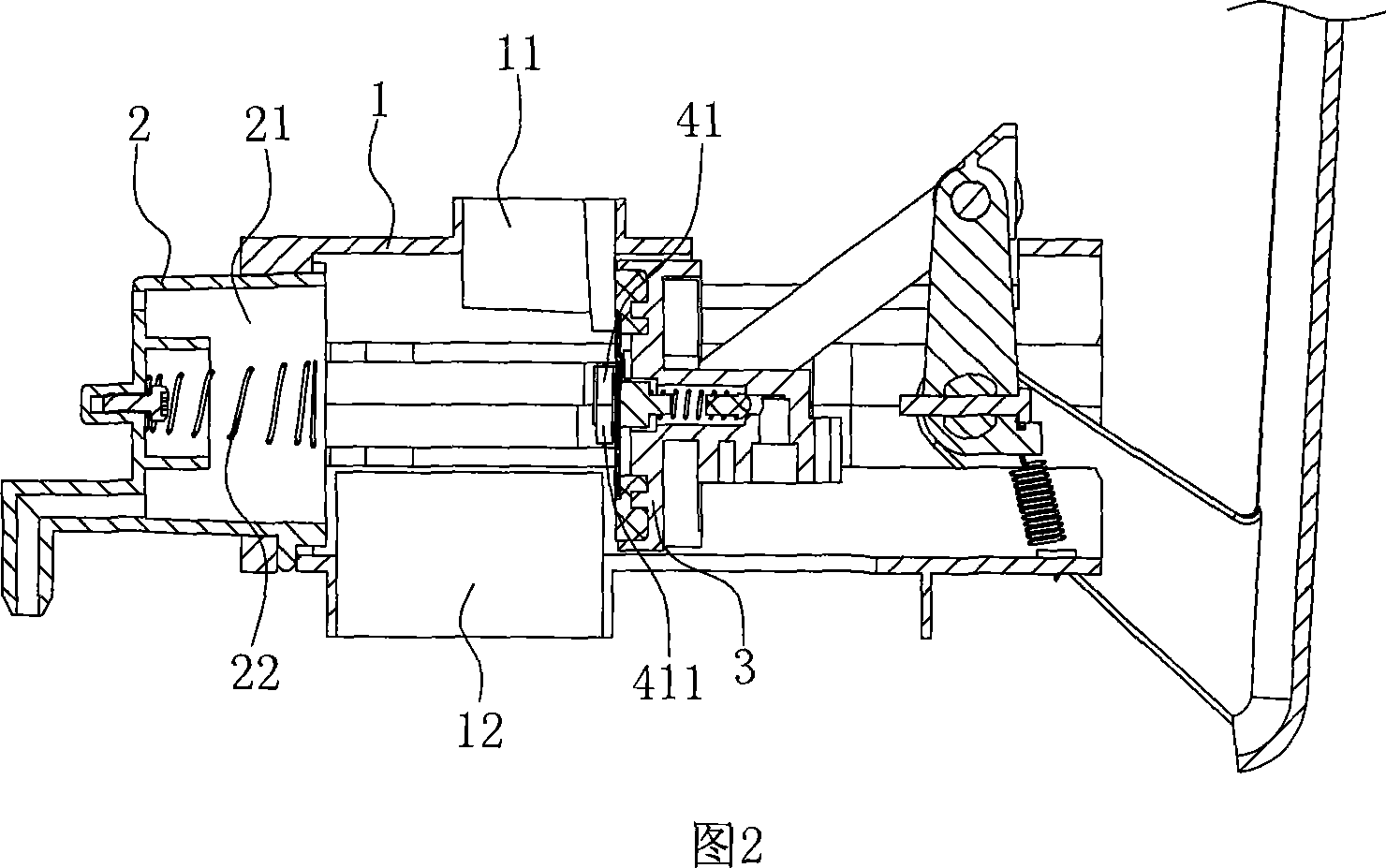

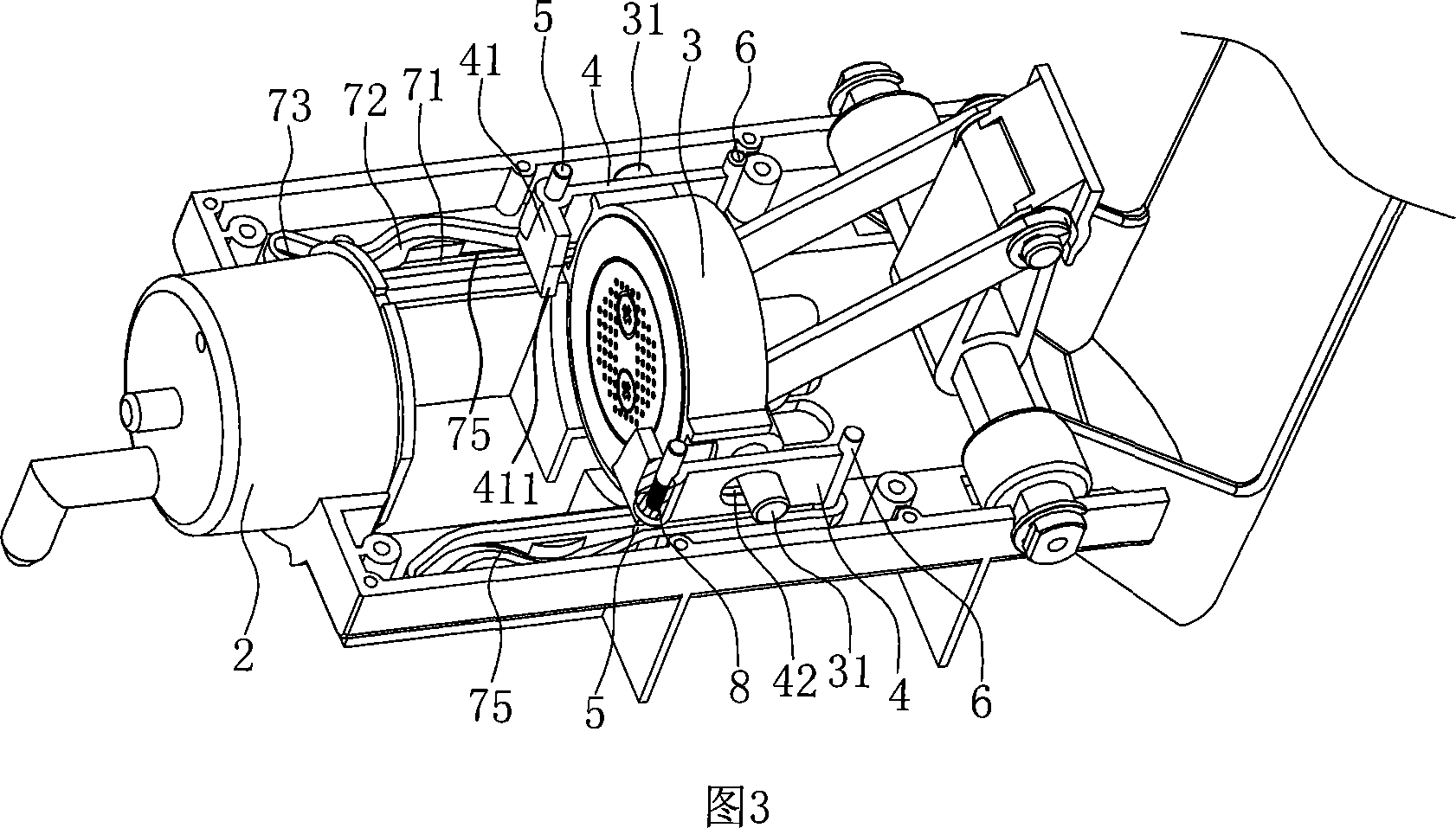

[0037] As shown in Figures 1 to 18, an automatic shedding mechanism for coffee pods in a coffee machine includes an organic base 1 and a first machine part 2 and a second machine part 3 arranged in the machine base 1, wherein the first machine part 2 The front end is fixed in the frame 1, the second mechanism 3 is limited to the rear end in the frame 1, the second mechanism 3 is limited to both sides in the frame 1, and the second mechanism 3 can be opposite to the first One machine part 2 slides back and forth, and the rear part of the first machine part 2 has a cavity 21, so the first machine part 2 and the second machine part 3 can form a seal that can accommodate the coffee pod 9 after being hermetically closed. There is a protruding ring 91 at the rear end of the coffee pod 9, and the coffee pod 9 is extracted in the sealed cavity. A comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com