Automatic package removing mechanism of beverage manufacturing device

A beverage preparation device and beverage bag technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of polluting coffee beverages, affecting the taste, and keeping coffee bags in the concave cavity, so as to ensure reliability and shedding process concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

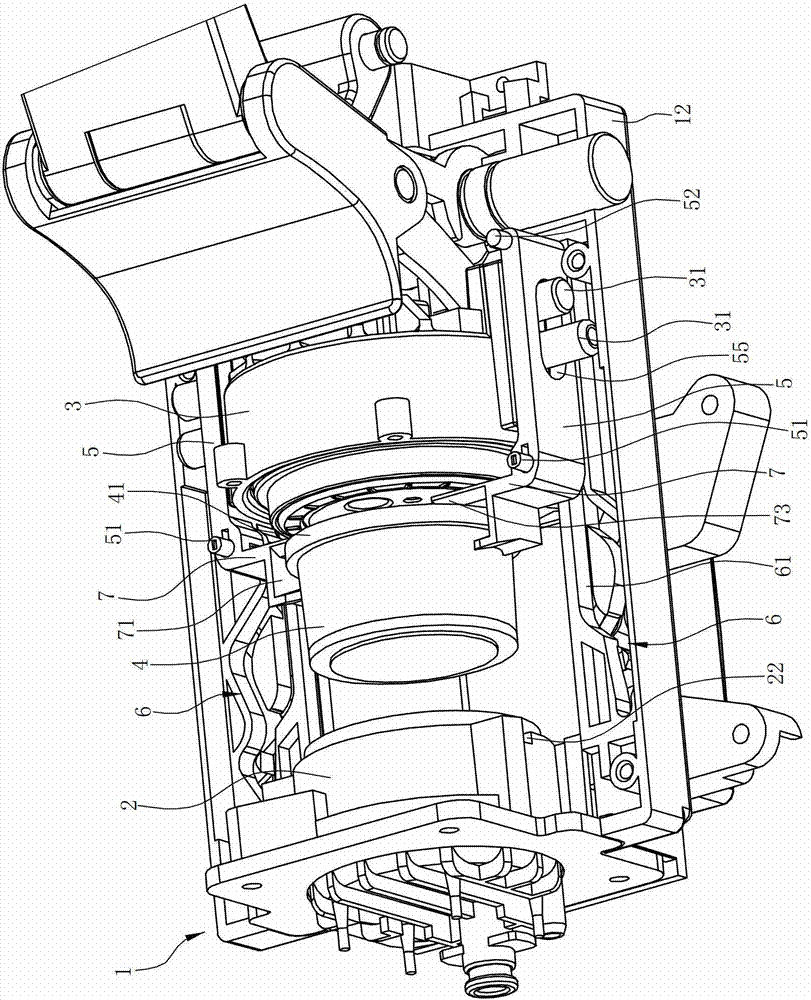

[0035] Such as Figure 1-16 Shown is a preferred embodiment of the present invention.

[0036] An automatic bag-dropping mechanism for a beverage preparation device, comprising an organic base 1, the machine base 1 is formed by coupling and connecting an upper shell 11 and a lower shell 12, and the lower shell 12 is provided with a bag-dropping opening 121.

[0037] There is a first component 2 with a liquid outlet, which is fixed at the front of the machine base 1 . The first component 2 has an accommodating chamber 21 for accommodating a beverage bag 4 with a ring-shaped edge 41 .

[0038] The second machine part 3 having a water inlet hole is bound at the rear of the base 1 and can slide forward and backward relative to the first machine part 2 . The second machine part 3 is composed of a shell and a piston body located in the shell. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com