Component mounting apparatus and component mounting method

A component assembly and component technology, applied in the field of component assembly devices, can solve the problem of not yet provided component assembly devices, etc., and achieve the effect of high-precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0054] Next, embodiments of the present invention will be described in detail with reference to the drawings.

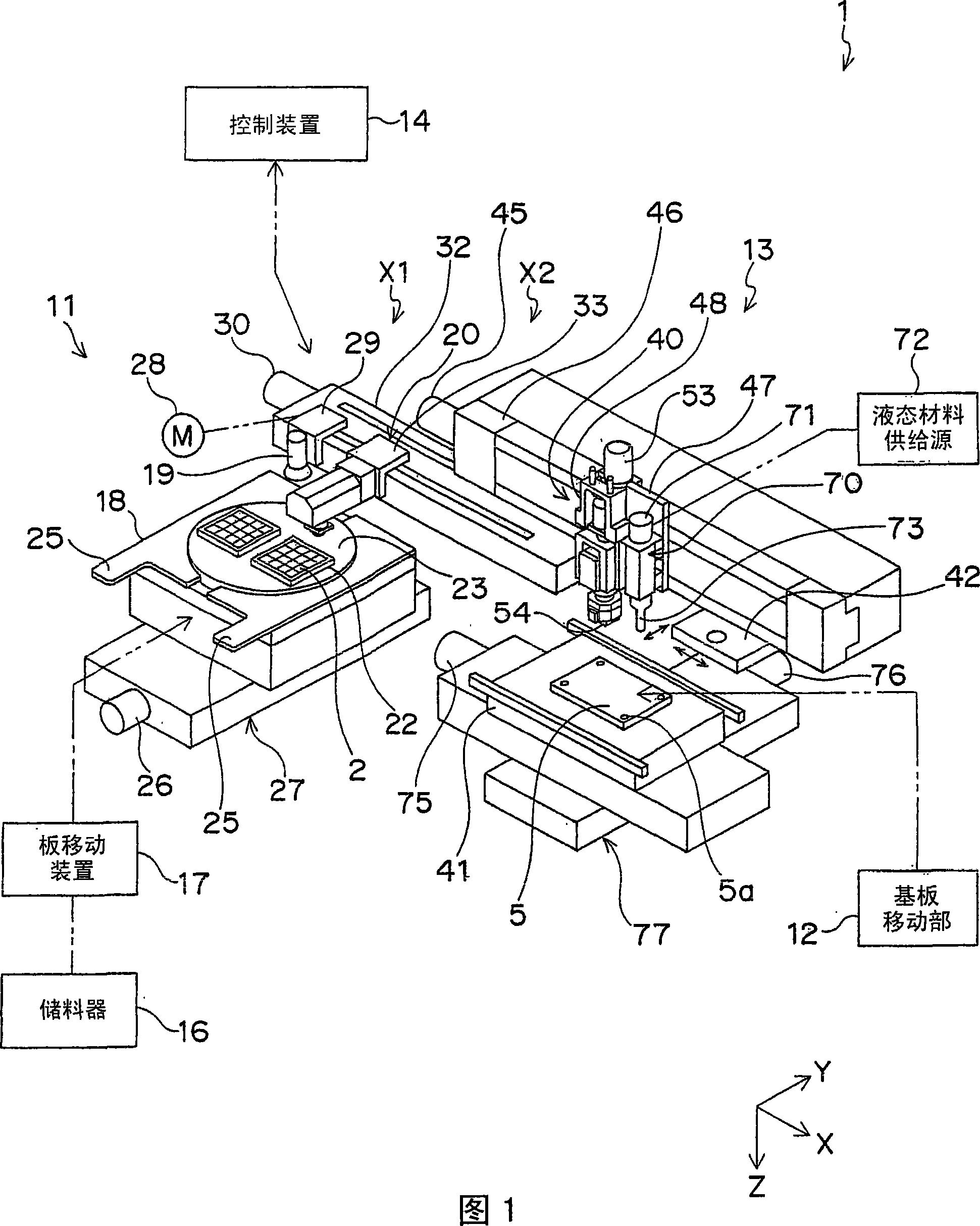

[0055] 1 to 4 show a component mounting apparatus 1 in a first embodiment of the present invention. The component mounting apparatus 1 is an apparatus for stack mounting a plurality of IC chips (components) on a substrate. Referring to Fig. 5A and Fig. 5B, IC chip (hereinafter simply referred to as "chip") 2 is provided with a plurality of pads (such as Au pads) 3 on one side (adsorption surface) 2a, and is provided on the other side (mounting surface 2b) Multiple buffer blocks (eg Au buffer blocks)4. FIG. 6 shows an example of a plurality of chips 2 stacked and mounted on a substrate 5 . As shown in FIG. 6 , a spacer 3 is also provided on the substrate 5 . The chip 2-1 of the first layer is mounted on the substrate 5, and the IC chip 2-2 of the second layer is mounted thereon. In this example, a total of four chips 2-1 to 2-4 are stack-mounted. The bumper 4 of ...

no. 2 approach

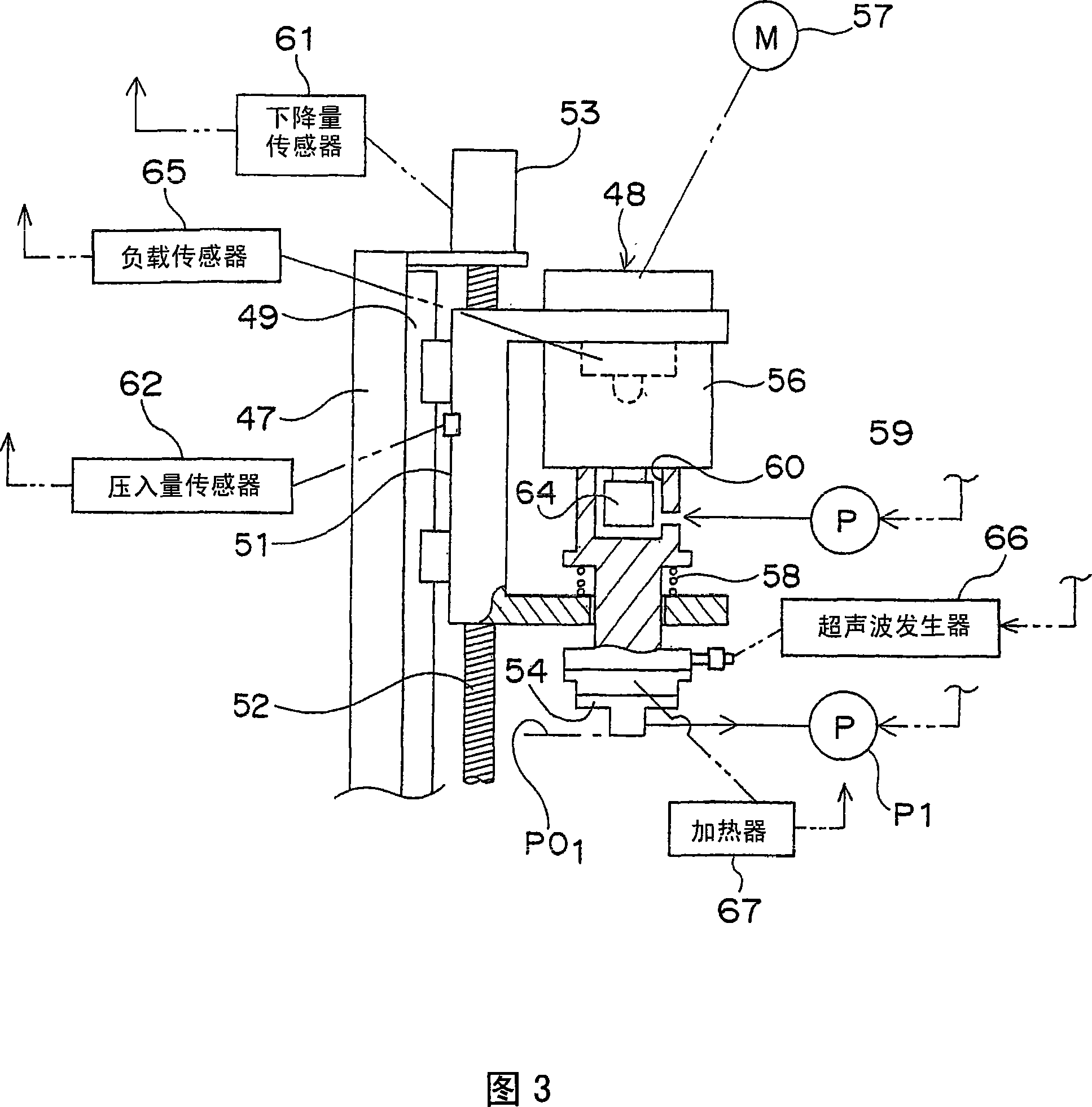

[0117] FIG. 9 shows the control device 14 in the second embodiment of the present invention. In this embodiment, the set pushing amount PHSET of each layer is stored in the data storage unit 101. n . Set the pressing amount PHSET n is a set value as follows, when the mounting head 48 holding the chip 2 on the suction nozzle 54 moves from the first reference height position HB 1 When descending toward the substrate 5 or the mounted chip 2, after the chip 2 held by the suction nozzle 54 contacts the substrate 5 or the mounted chip 2, the assembly head 48 is further lowered, thereby moving the suction nozzle 54 from the initial position P0 1 (Refer to FIG. 3 ) The setting value of the press-fitting distance upward relative to the nozzle support portion 56 in the vertical direction. In addition, the mounting reference height calculating unit 103 sets the set pushing amount PHSET n and the actual pushing amount PHAC detected by the pushing amount sensor 62 as the measured value...

no. 3 approach

[0134] FIG. 12 shows the control device 14 in the third embodiment of the present invention. In this embodiment, the mounting reference height calculation unit 103 uses the actual moving height ZAC as an actual measurement value of the mounting head 48 when the chip 2 is mounted on the substrate 5 or the mounted chip 2 n For assembly reference height H n calculation. The actual moving height ZAC n It is detected by the drop amount sensor 61 . In addition, the actual mobile height ZAC n The datum is the first datum height position HB 1 , and positive downwards in the vertical direction.

[0135] Operations of the control device 14 and the assembly unit 13 will be described with reference to the flowchart of FIG. 13 . In steps S13-1 to S13-12, the processes of steps S13-1, S13-2, S13-4 to S13-9, S13-11, and S13-11 are the same as the processes of the corresponding steps in FIG. 7 . In particular, in step S13-4, the first target moving height calculation unit 104 calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com