Linear guide device

A technology of guiding devices and guide rails, which is applied in the direction of linear motion bearings, bearings, bearing components, etc., and can solve problems such as poor assembly of sliders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

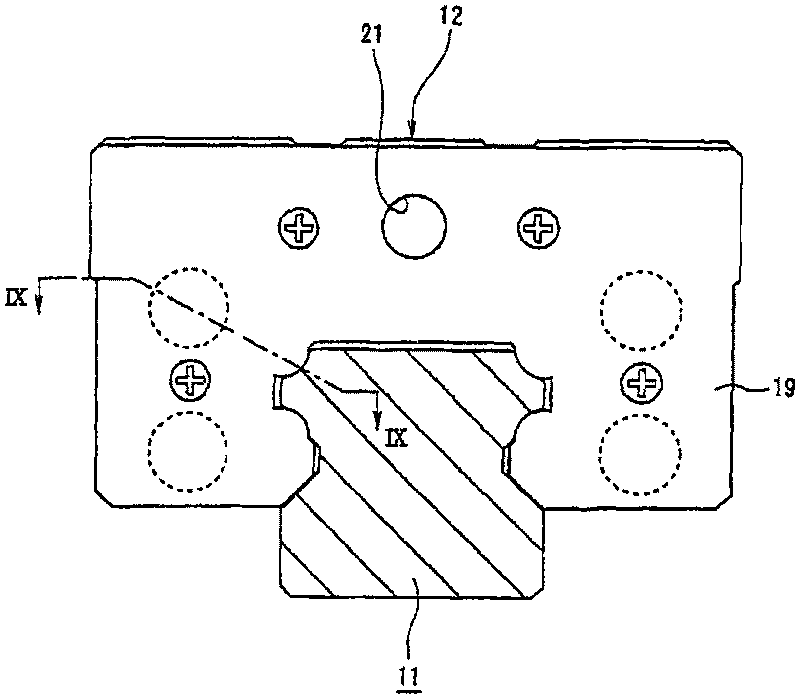

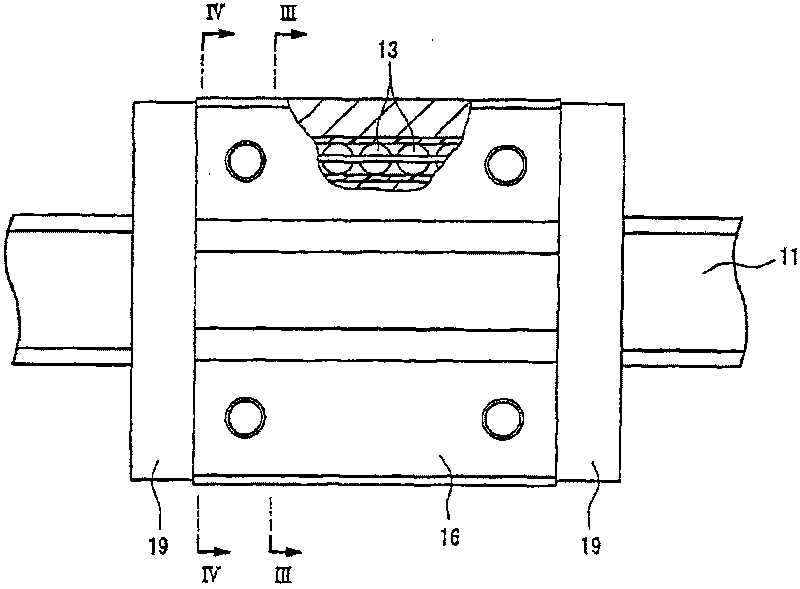

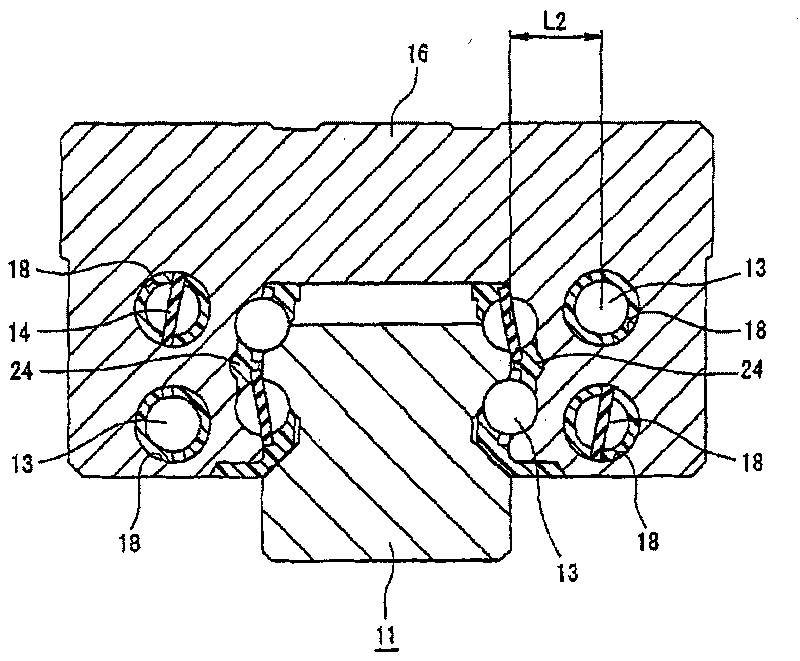

[0040] exist figure 1 with figure 2 Among them, the linear guide device of the first embodiment of the present invention is composed of the following parts: a guide rail 11 formed in a straight line; a slider 12 that relatively moves in the length direction of the guide rail 11; a freely rolling assembly on the slider 12 A plurality of balls 13 as rolling bodies inside; and four spacing maintaining strips 14 (refer to image 3 with Figure 4 ).

[0041] The guide rail 11 is made of metal materials such as steel, and has rolling grooves 15 on the side of the rail L1 、15 L2 、15 R1 、15 R2 (refer to Figure 5 ). These track side rolling element rolling grooves 15 L1 ~15 R2 The rolling grooves of the two track side rolling elements in the 15 L1 、15 R1The intersection of the upper surface part 111 of the guide rail 11 and the left and right side parts 112, 112 is formed along the length direction of the guide rail 11, and the remaining two rail side rolling element roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com