Piezoelectric resonator and method for manufacturing thereof

A technology for piezoelectric vibrators and manufacturing methods, which is applied to electrical components, impedance networks, etc., can solve problems such as limiting the miniaturization of piezoelectric vibrators, and achieve the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

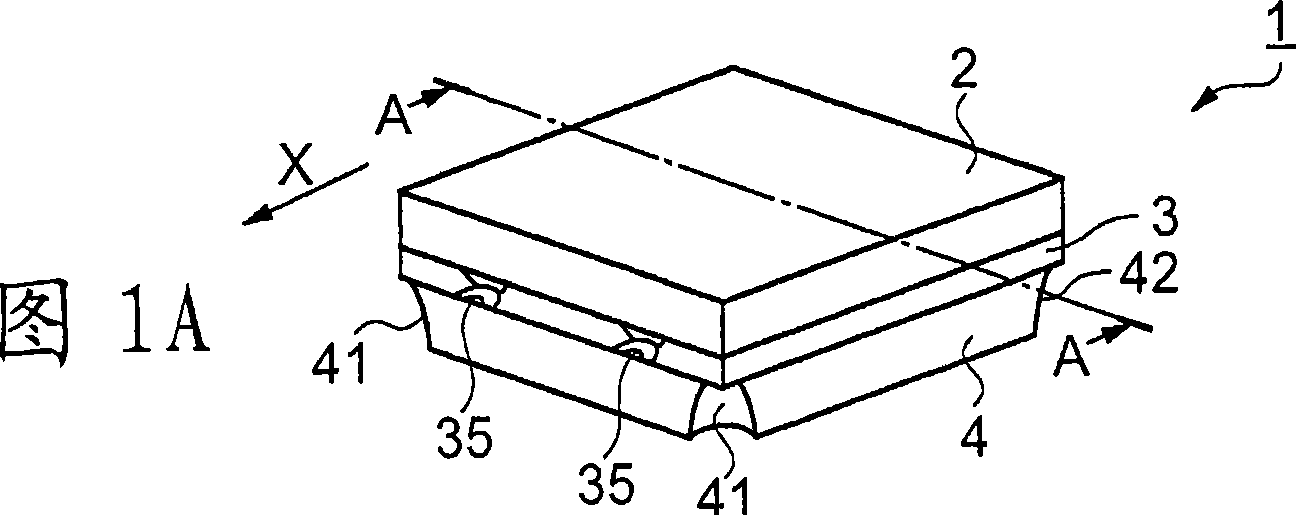

[0037] FIG. 1 shows a piezoelectric vibrator 1 in the present embodiment of the present invention.

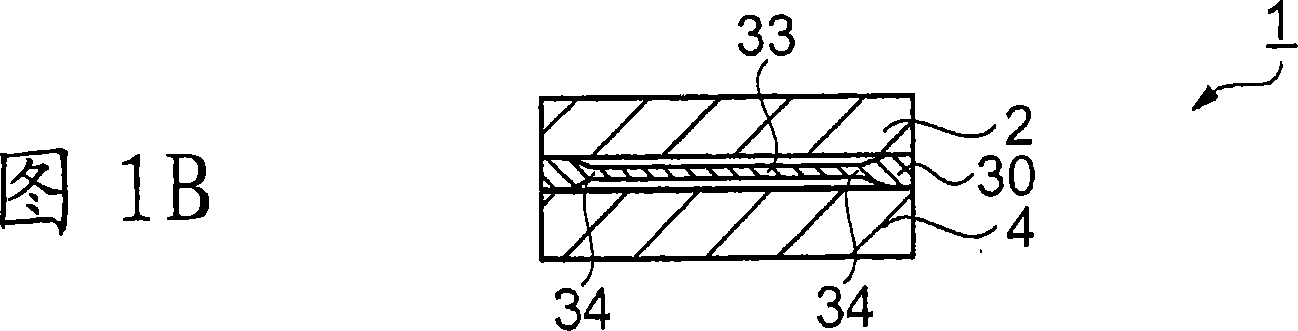

[0038] FIG. 1A is a perspective view of a piezoelectric vibrator 1 , and FIG. 1B shows a cross-sectional view along line A-A of FIG. 1A .

[0039]In addition, FIG. 2 shows an exploded perspective view of the piezoelectric vibrator 1 . The piezoelectric vibrator 1 has a cover substrate 2 , a vibrator substrate 3 , and a base substrate 4 .

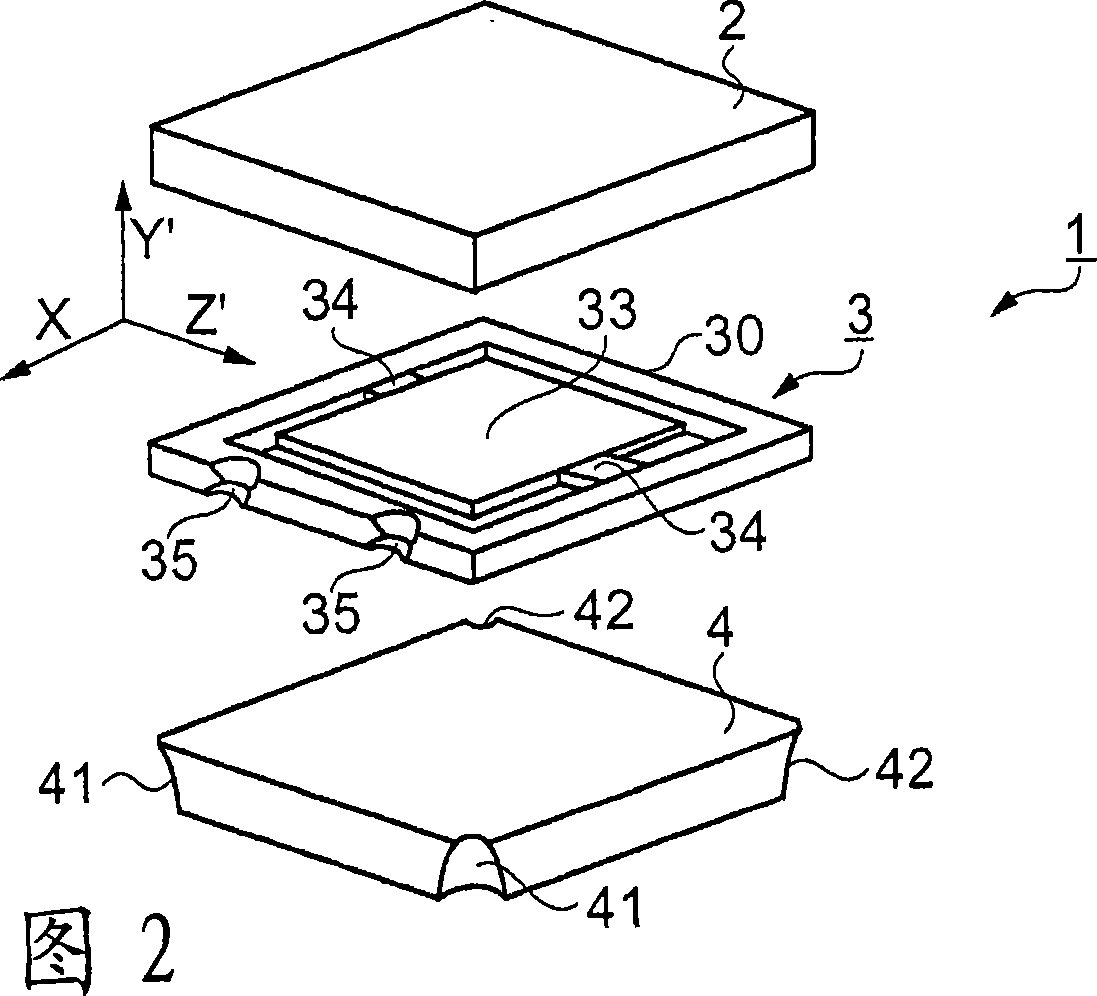

[0040] FIG. 3A shows a plan view of the transducer substrate 3 viewed from the lid substrate 2 side, and FIG. 3B shows a plan view of the transducer substrate 3 viewed from the base substrate 4 side.

[0041] In FIG. 1A and FIG. 2 , the piezoelectric vibrator 1 is formed by overlapping the cover substrate 2 on the vibrator substrate 3 supported on the base substrate 4 . The vibrator substrate 3 is sandwiched between the cover substrate 2 and the base substrate 4 and bonded.

[0042] The base substrate 4 is a substantially rectangular plate...

no. 2 Embodiment approach

[0091] FIG. 8 shows two types of vibrator substrates 3 according to this embodiment of the present invention.

[0092] 8A is a plan view of the transducer substrate 3 viewed from the base substrate 4 side, and FIG. 8B is a plan view of another transducer substrate 3 viewed from the base substrate 4 side.

[0093] In FIG. 8A , the support portions 34 of the vibrating piece 33 are aligned on the side of the frame portion 30 on the side of the concave portion 35 . The vibrating piece 33 and the frame portion 30 are penetrated by the hollow 314 .

[0094] The second excitation electrode 32 is provided on the surface of the vibrator substrate 3 that faces the base substrate 4 . More specifically, it is provided on the vibrating piece 33 , one of the two support portions 34 , and the surface of the frame portion 30 facing the base substrate 4 . Here, the excitation electrode 32 is not provided in the vicinity of the concave portion 35 . The third electrode 36 is provided on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com