Multilayer light bearing wall body composite board

A multi-layer composite and composite board technology, which is applied in building components, buildings, building structures, etc., can solve the problem that wall boards cannot achieve thermal insulation at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

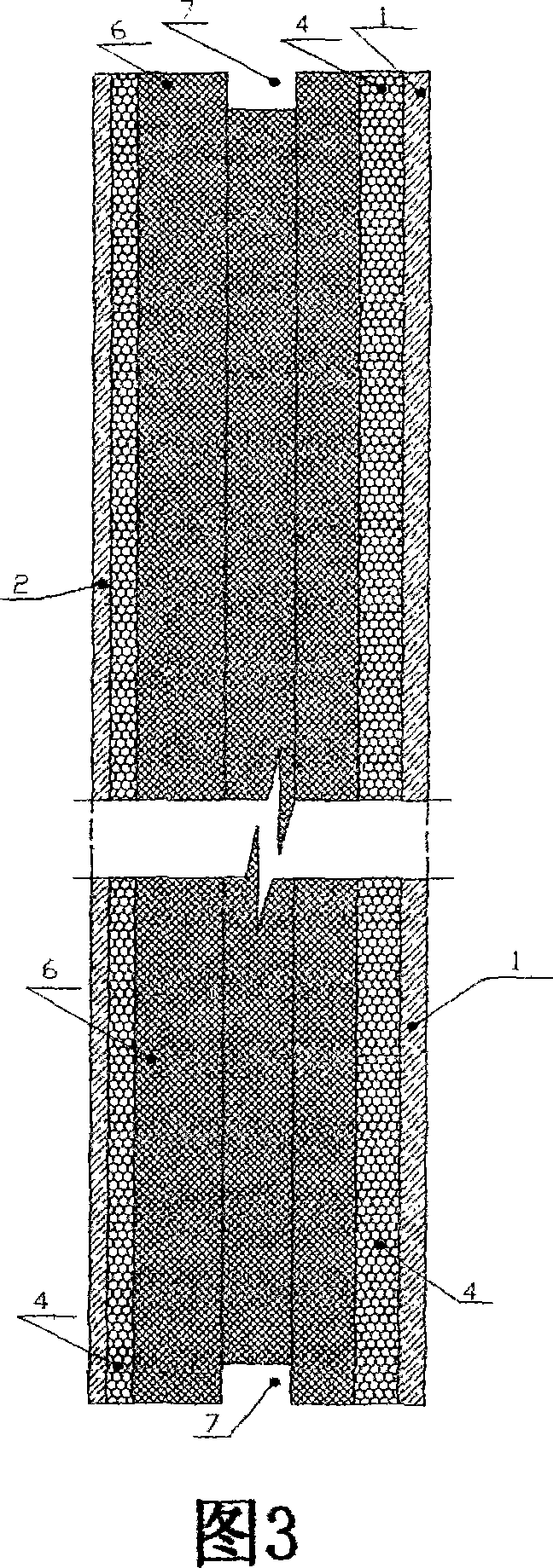

[0011] According to the first embodiment of the present invention; the transverse sawtooth reinforcing plate layer is divided into left and right tooth types, and there are two layers in total. The end surface of the first layer is connected to the outer wall surface while the tooth valley of the other end surface is not connected to the inner wall surface. The middle gap is 300mm, and the tooth tip is connected to the inner wall surface. The end face of the second layer is connected to the inner wall, the tooth valley of the other end is not connected to the outer wall, the gap is 300mm, and the tooth tip is connected to the outer wall. Fill the gap with heat insulating material, so as to block the transmission of thermal bridges, and the tooth tips connect the inner and outer layers of the wall, which has better structural strength and compressive strength while maintaining a lighter overall mass.

[0012] Preferably, the outer layer of the multi-layer lightweight load-beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com