Modification for hook-gear type positioning constitution of drag chain injection

A hook-tooth and zipper technology, applied to fastener components, other household appliances, household appliances, etc., can solve problems such as insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

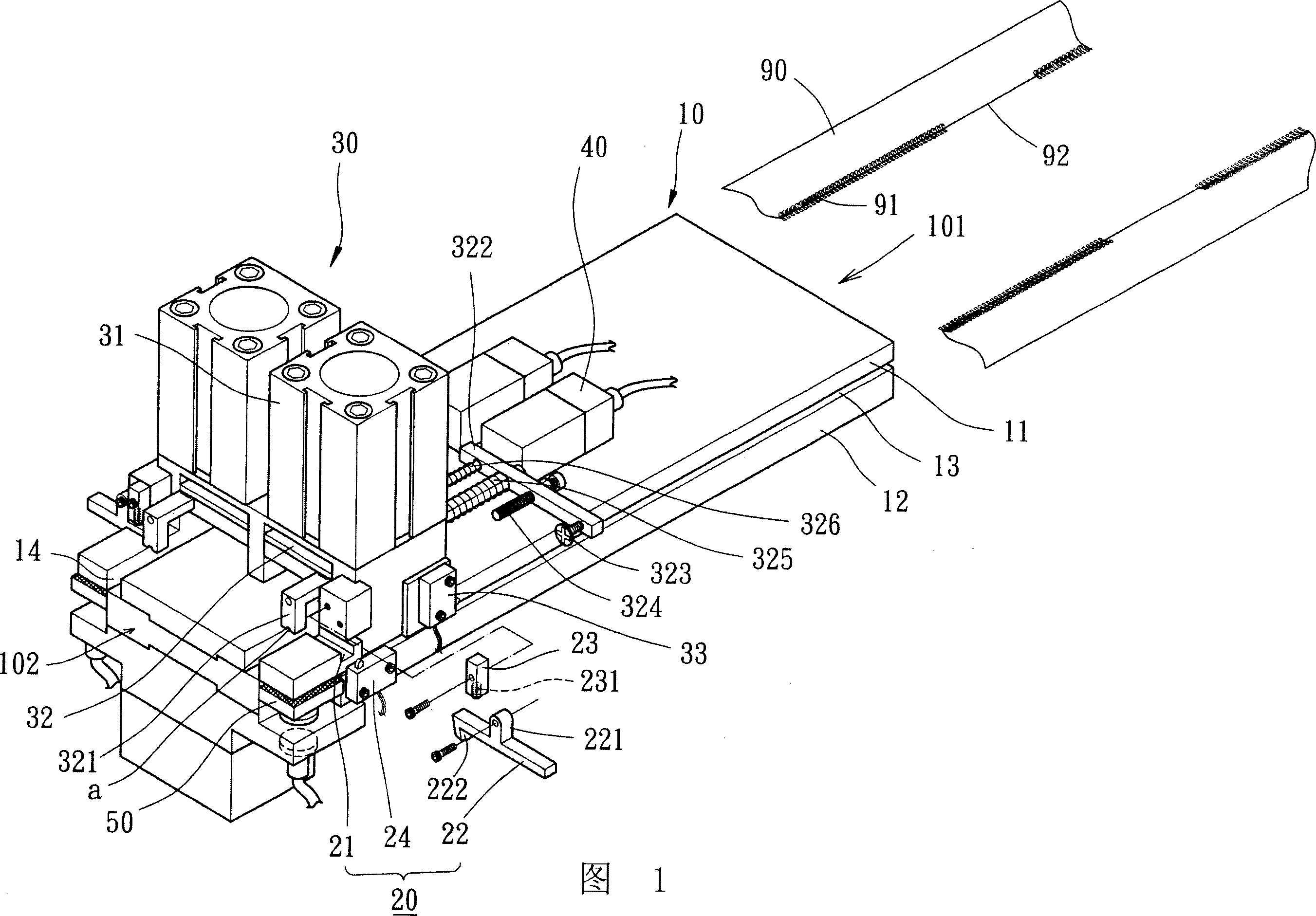

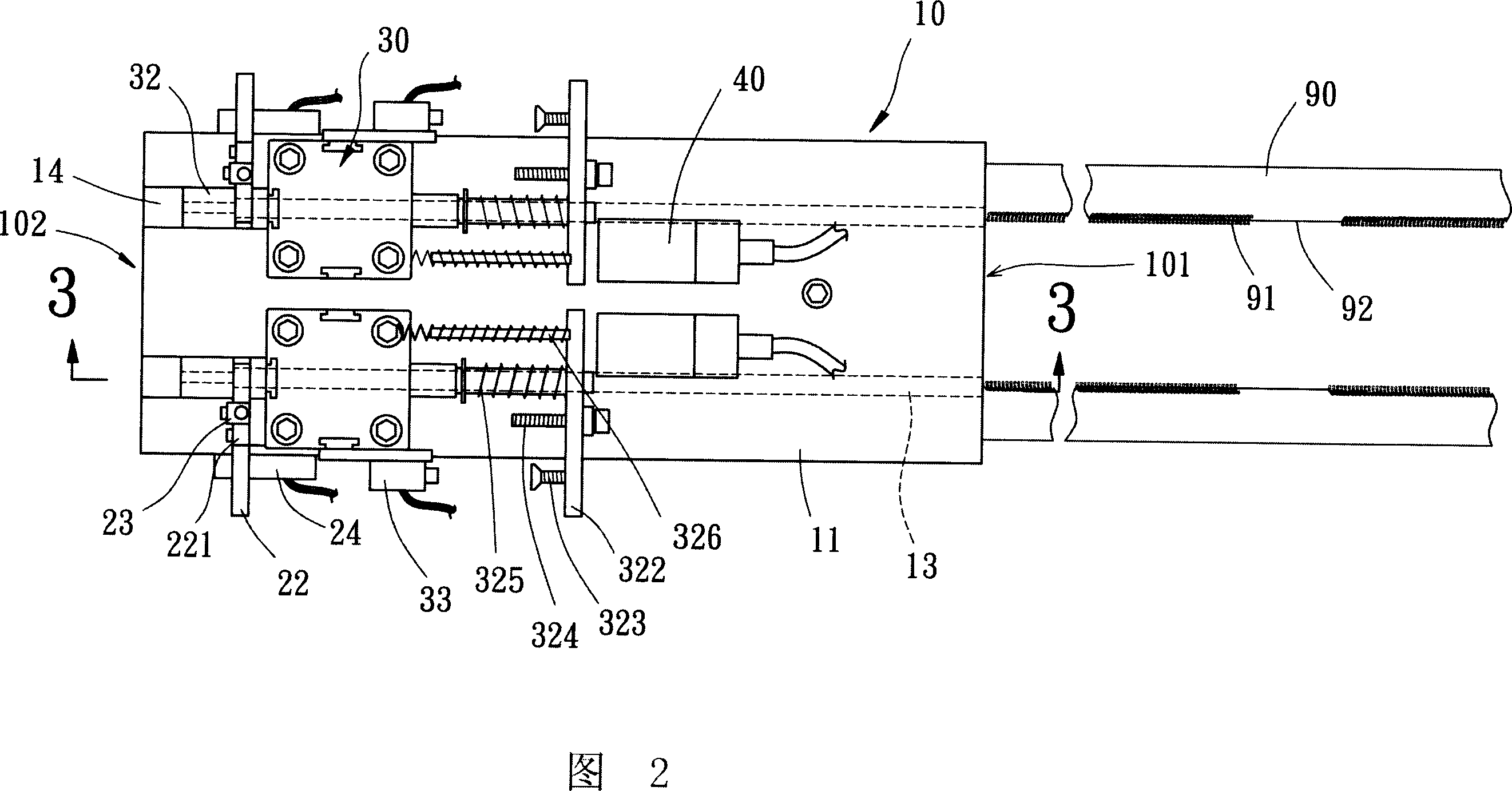

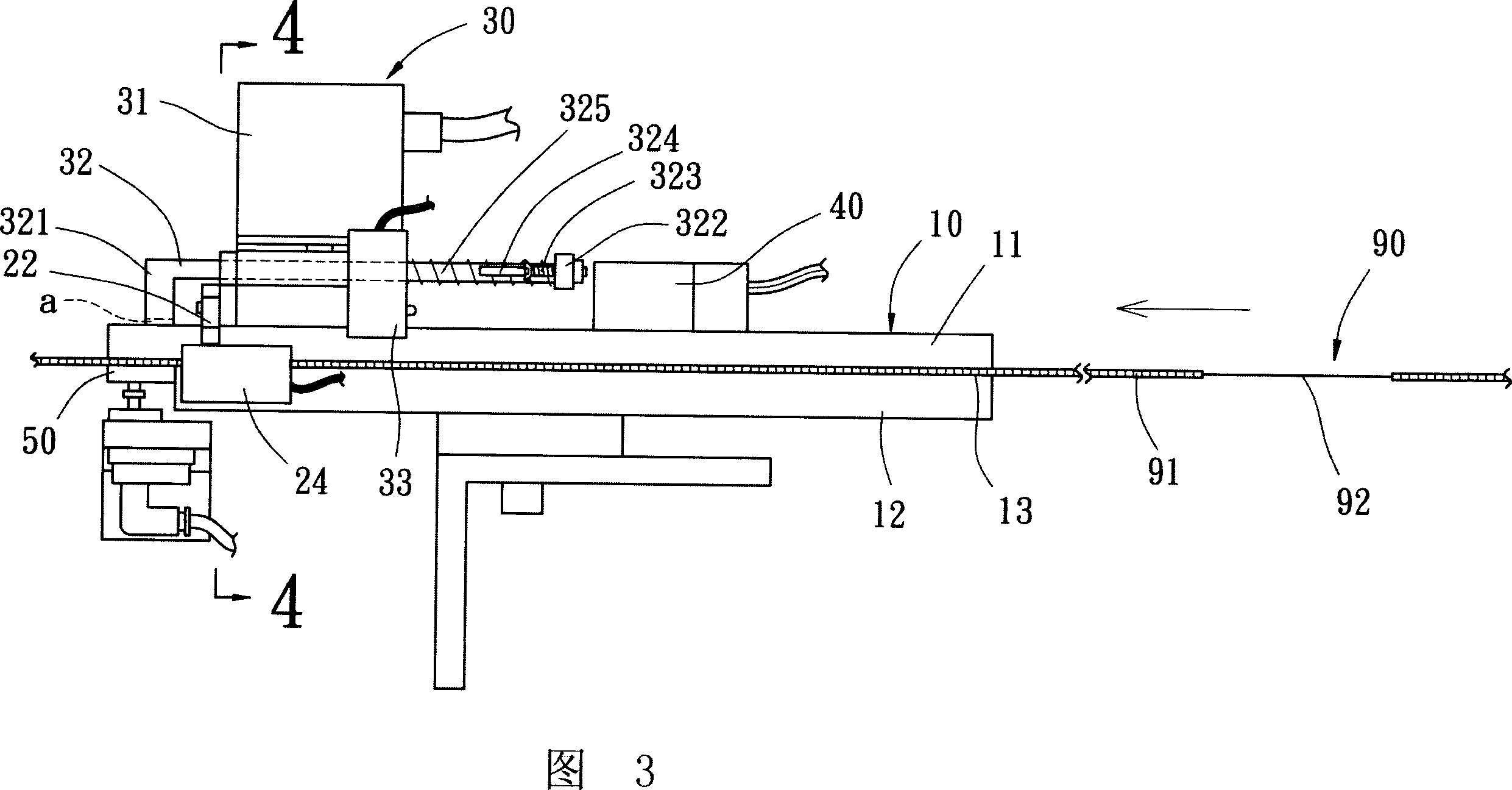

[0019] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below with accompanying drawings.

[0020] As shown in Figures 1 to 3, the improvement of the hook-tooth positioning structure of the zipper in the preferred embodiment of the present invention is mainly to sew two continuous zipper cloth strips 90 with several zipper teeth 91, and the zipper cloth strips The zipper teeth 91 of 90 protrude from the corresponding inner side of the zipper cloth strip 90, and the two zipper teeth 91 form a missing tooth portion 92 with each other, and the two zipper cloth strips 90 are separated by a pulling assembly [ not shown] lead and pull, so that the two zipper cloth strips 90 are guided through the positioning structure of the present invention to form precise movement and positioning, and then the two zipper cloth strips 90 are introduced into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com