Double tube high voltage gas discharge lamp electronic ballast control system

An electronic ballast and high-pressure gas technology, which is applied in the field of electronic ballast control system, can solve problems such as high lamp temperature, lamp burnout, and unstable lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

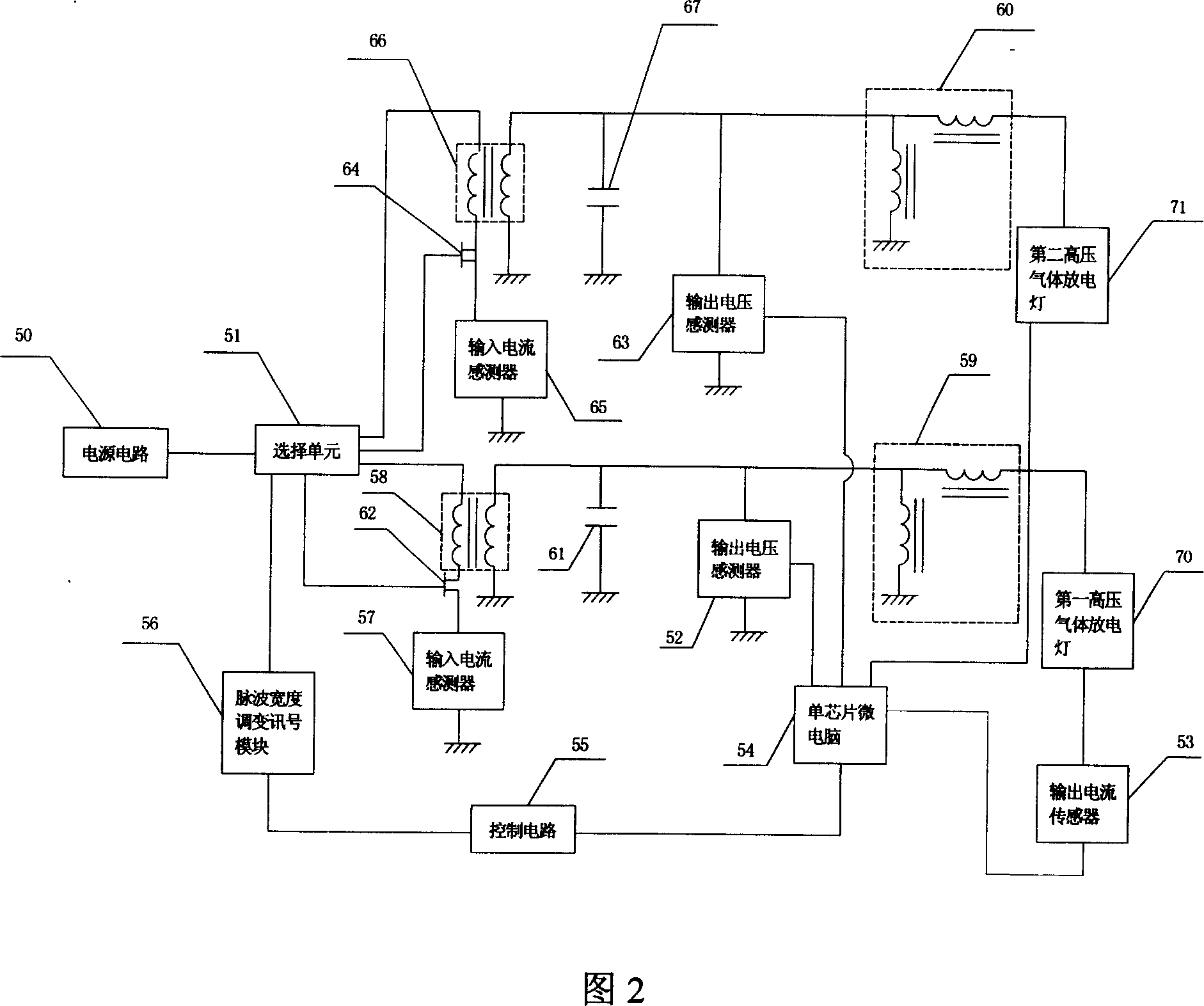

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

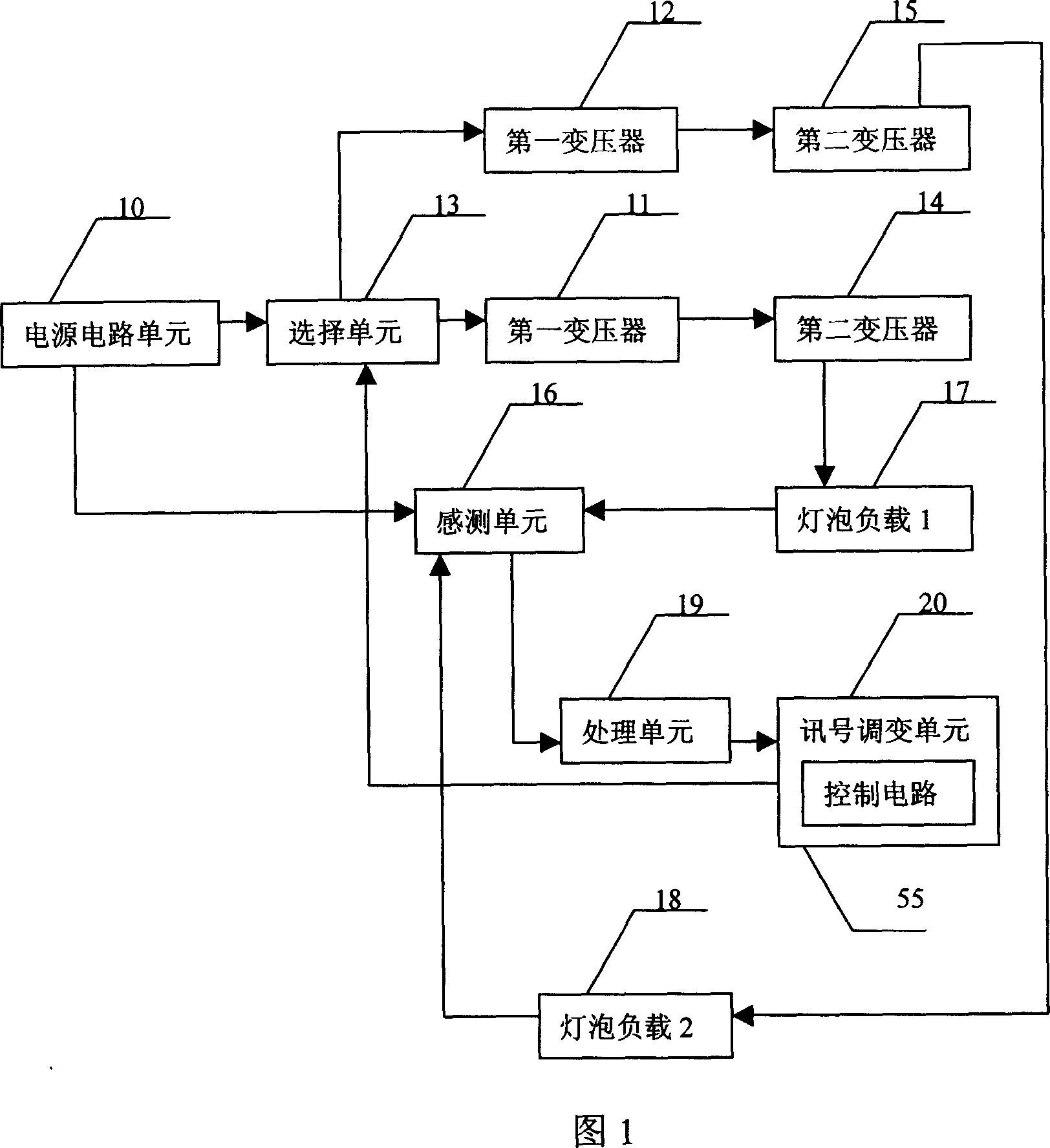

[0030] Please refer to FIG. 1 , which is a schematic block diagram of the system of the present invention. It includes a power supply circuit 10 , first transformers 11 , 12 , selection unit 13 , second transformers 14 , 15 , sensing unit 16 , processing unit 19 , signal modulation unit 20 , bulb load 17 , and bulb load 18 .

[0031] The power supply circuit 10 is used to provide the power supply for the operation of the electronic ballast;

[0032] The selection unit 13 is used to select the bulb load 17 or the bulb load 18 to be driven or drive them simultaneously;

[0033] The first transformers 11, 12: used to supply the power conversion voltage output by the power supply circuit 10 to the second transformers 14, 15 for use;

[0034] The second transformer 14, 15 is used to convert the output of the first transformer 11, 12 into the voltage required to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com