Electricity-heated defrosting evaporator

An evaporator and electric heating wire technology, applied in the field of automatic frosting devices, can solve problems such as incomplete, unstable work, and failure of the refrigeration system to defrost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment of the present invention, further describe in detail:

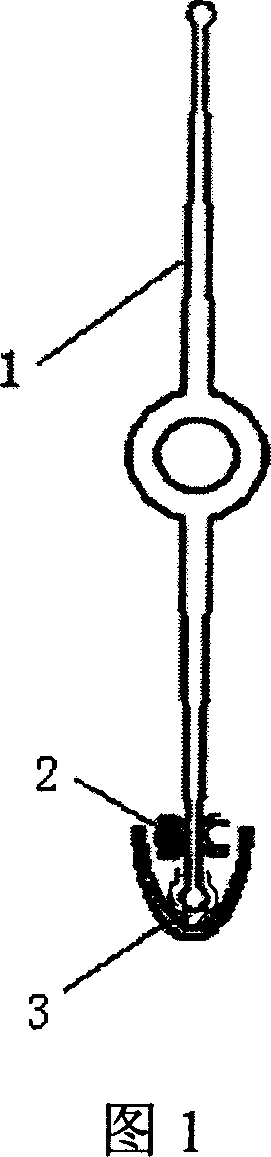

[0010] As shown in Figure 1, it consists of a double-groove finned tube 1, a heating wire 2, and a U-shaped plastic water tray 3. The double-groove fin tube 1 is formed by integral die-casting of aluminum alloy; the U-shaped plastic water tray 3 is formed by extrusion of plastic. The central opening of the U-shaped plastic water tray is plugged in on the fins of the aluminum alloy fin tube, and the heating wire is installed in the double grooves of the fins 28 . Figure 2 is composed of multiple finned tubes arranged in parallel to form a cold row, that is, an aluminum alloy evaporator. The fins of the finned tubes form a 90-degree angle with the horizontal direction. There are concave grooves on both sides of each finned tube, and the heating wire It is installed in a concave groove, and each finned tube is equipped with a U-shaped plastic water tray, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com