Special-shaped barrel automatic fitting and welding device

A butt welding and cylinder technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, high labor intensity, and low efficiency of welding robots, so as to speed up welding work and save standby time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

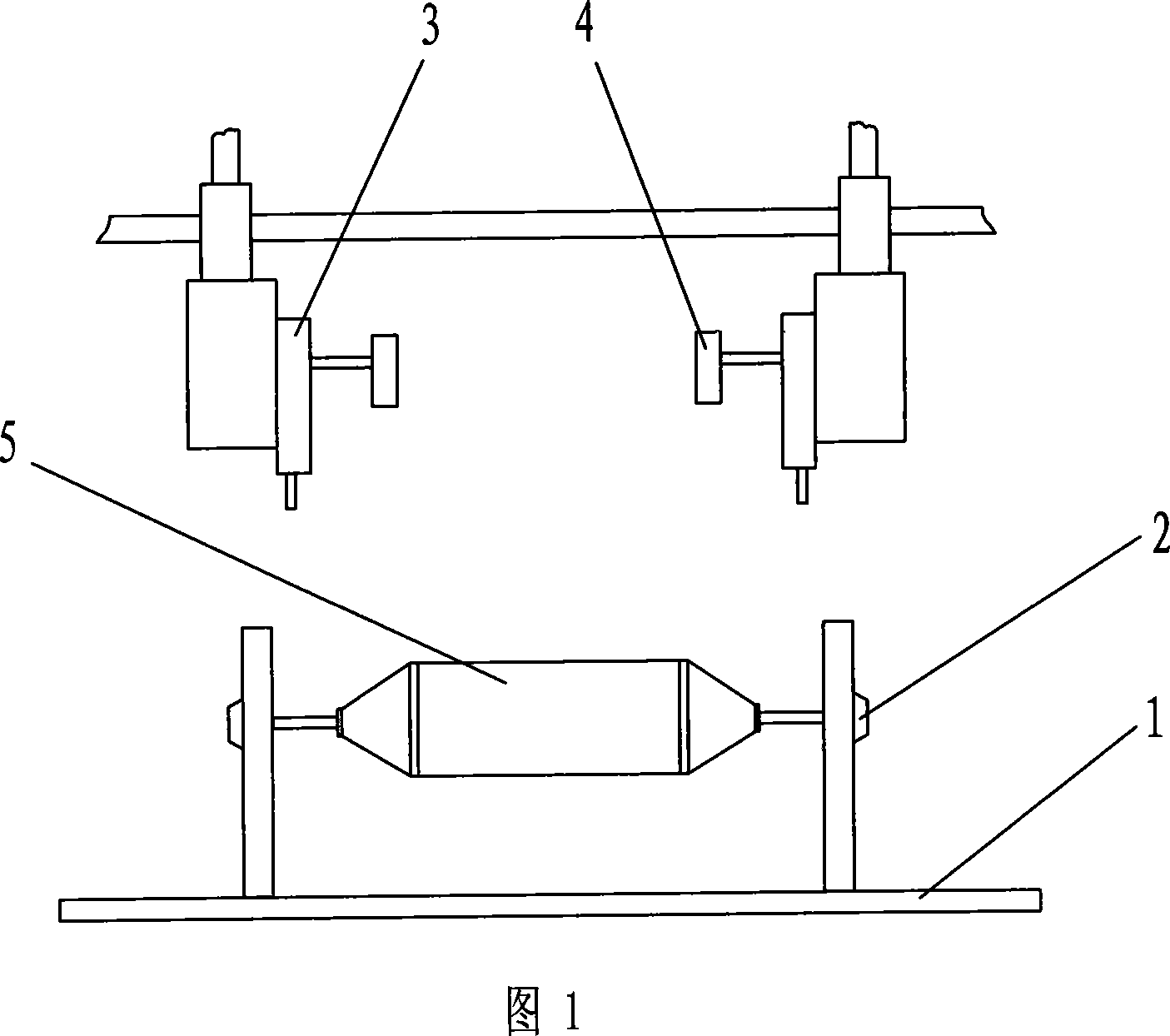

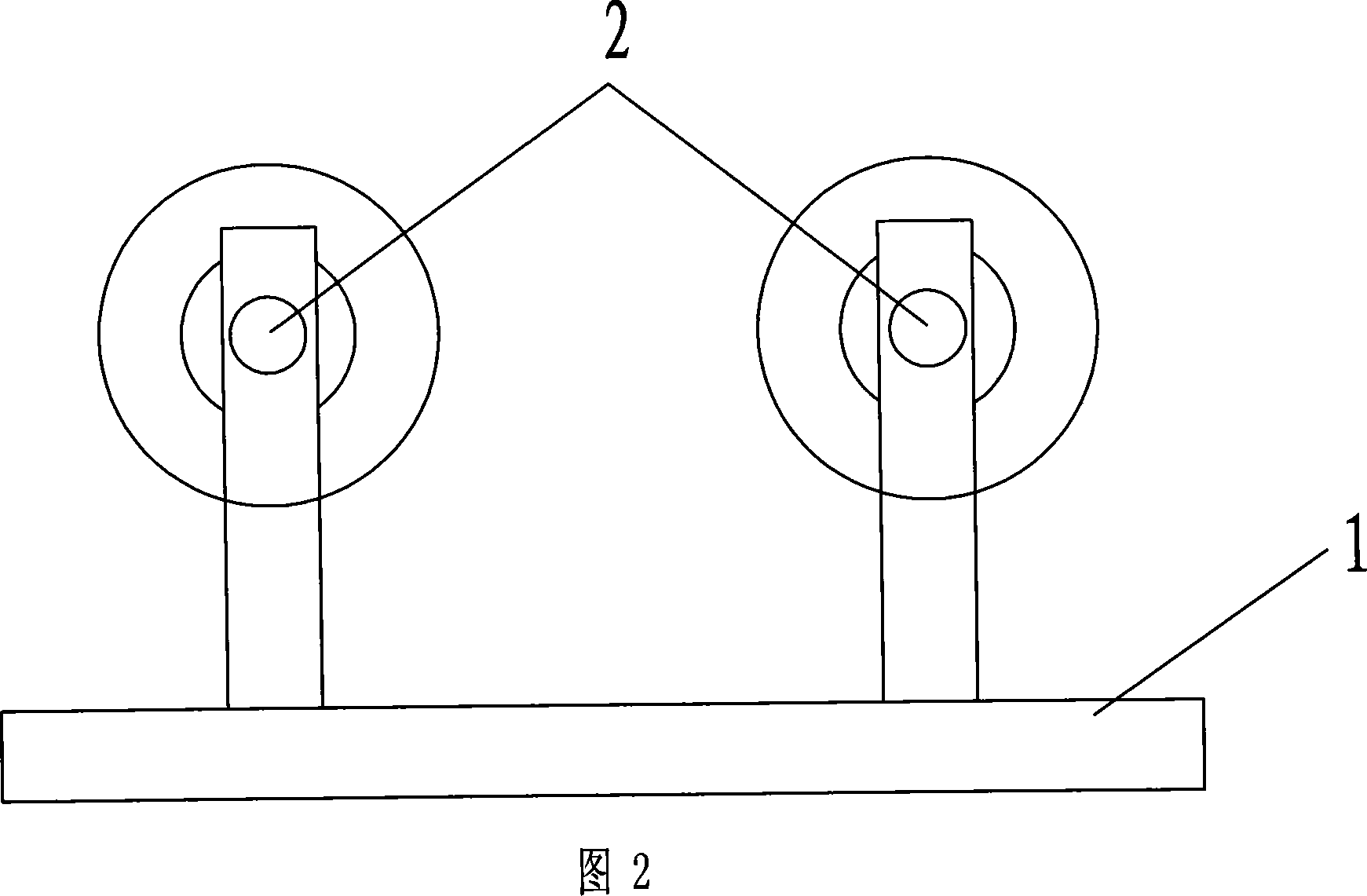

[0018] See accompanying drawing 1, 2, welding device of the present invention is made of clamping turntable 1, fixture 2, welding part 3 and welding seam positioning part 4; Two sets of fixtures 2 are arranged on the top; when one set of fixtures 2 is at the welding station and the other is at the station to be installed, the operator can unload the welded cylinder 5 and install the cylinder 5 to be welded; the cylinder The body 5 can be cylinders of various specifications and shapes, such as circular, elliptical, track-shaped, polygonal, etc.; then, by rotating the clamping turntable 1, reciprocating rotation is realized to improve work efficiency.

[0019] The fixture 2 is driven by a servo motor, and can rotate one circle along the horizontal axis (X axis) at a constant speed, so that all parts of the clamped cylinder body 5 to be welded to be welded can be welded through the welding part 3 . For the convenience of observation and protection of the operator, a baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com