Spiral mechanism for horizontal centrifugal machine

A decanter centrifuge and screw mechanism technology, applied in the field of screw mechanism, can solve the problems of friction between the screw and the feeding pipe, reduced sedimentation and separation effect, wear of the screw outlet, etc., so as to improve work efficiency, reduce maintenance costs, extend the The effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

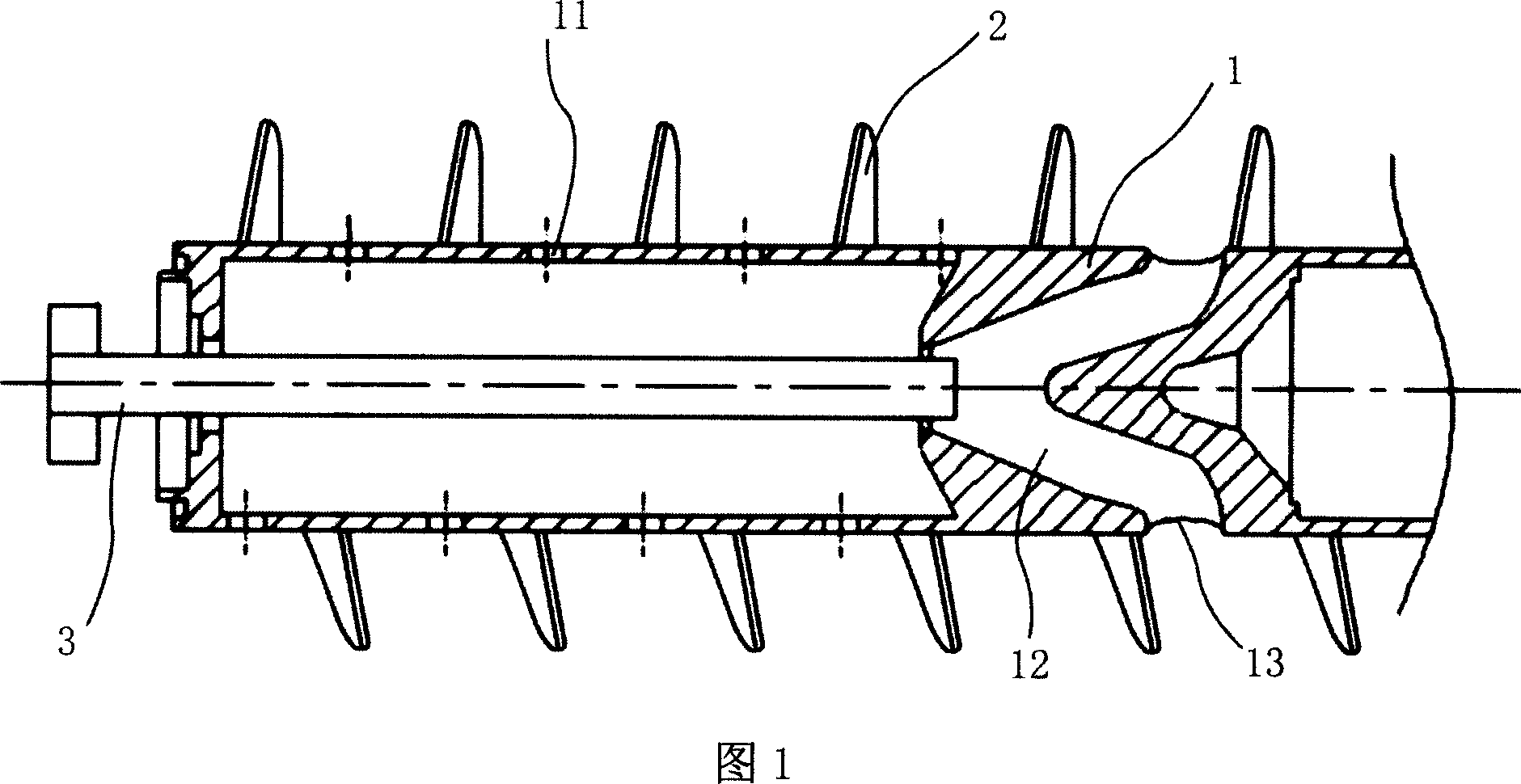

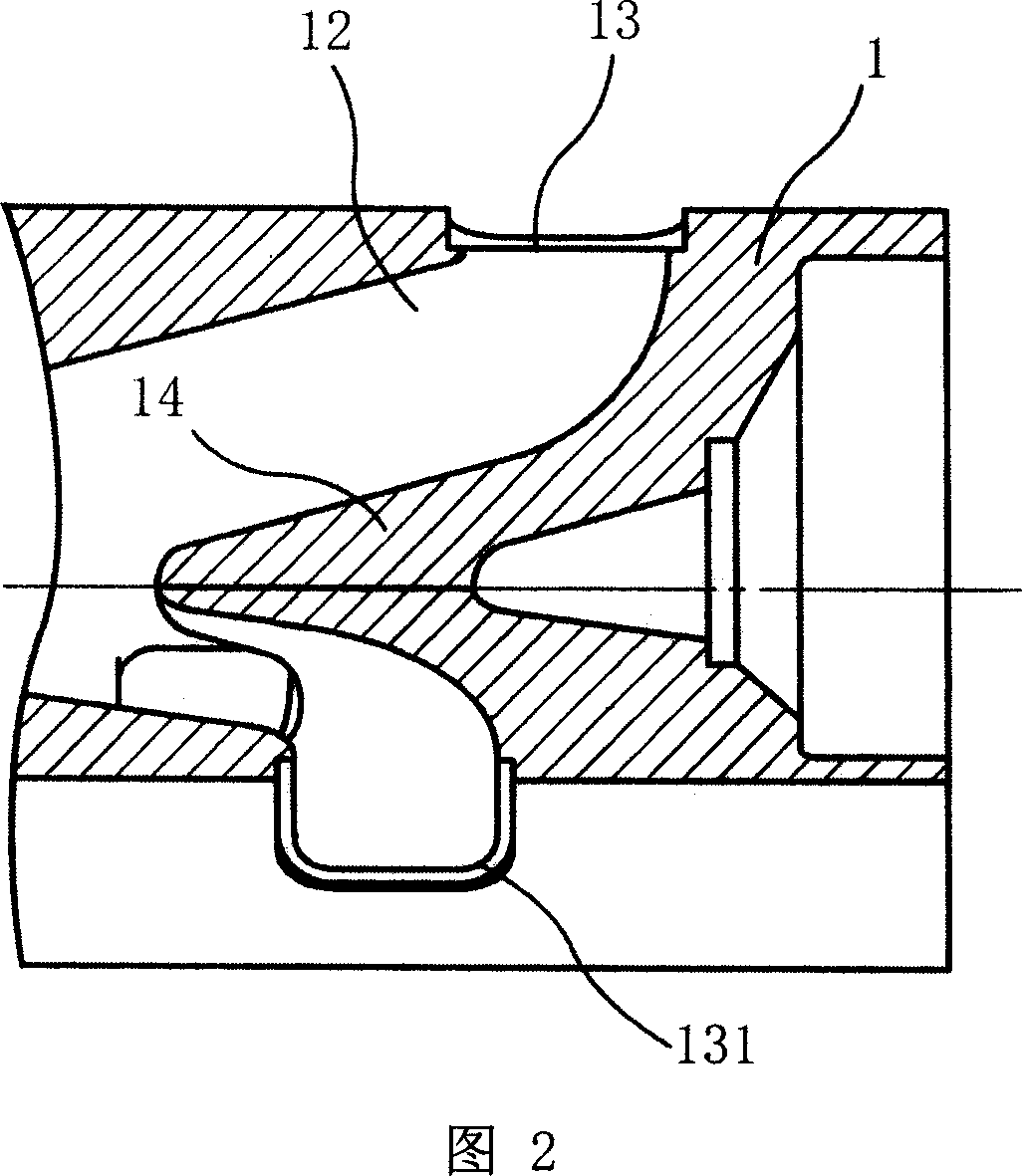

[0012] The screw mechanism of the decanter centrifuge as shown in Figure 1 and Figure 2 includes a screw blade 2 and a screw cylinder 1, and a plurality of leakage holes 11 are arranged on the circumferential wall of the spiral cylinder 1, corresponding to the outlet of the feed pipe 3 of the centrifuge. The circumferential wall of the spiral barrel 1 of the section is provided with mutually symmetrical 2-3 discharge ports 13, and a single discharge port 13 of the screw feed cavity is connected with an independent channel 12, and the discharge port 13 and the independent channel 12 are in common. The spiral feeding chamber structure is formed, each independent channel 12 is connected with the feeding chamber cavity, and the three outlets 13 are arranged at intervals of 120 degrees from each other with the axis of the spiral as the symmetrical center, and the three outlets of the spiral feeding chamber A conical acceleration bucket 14 is arranged between the symmetrical discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com