Horizontal freezer with defrost function

A horizontal and functional technology, applied in the field of horizontal freezers, can solve the problems of easily damaged evaporator, high energy consumption, and degassing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

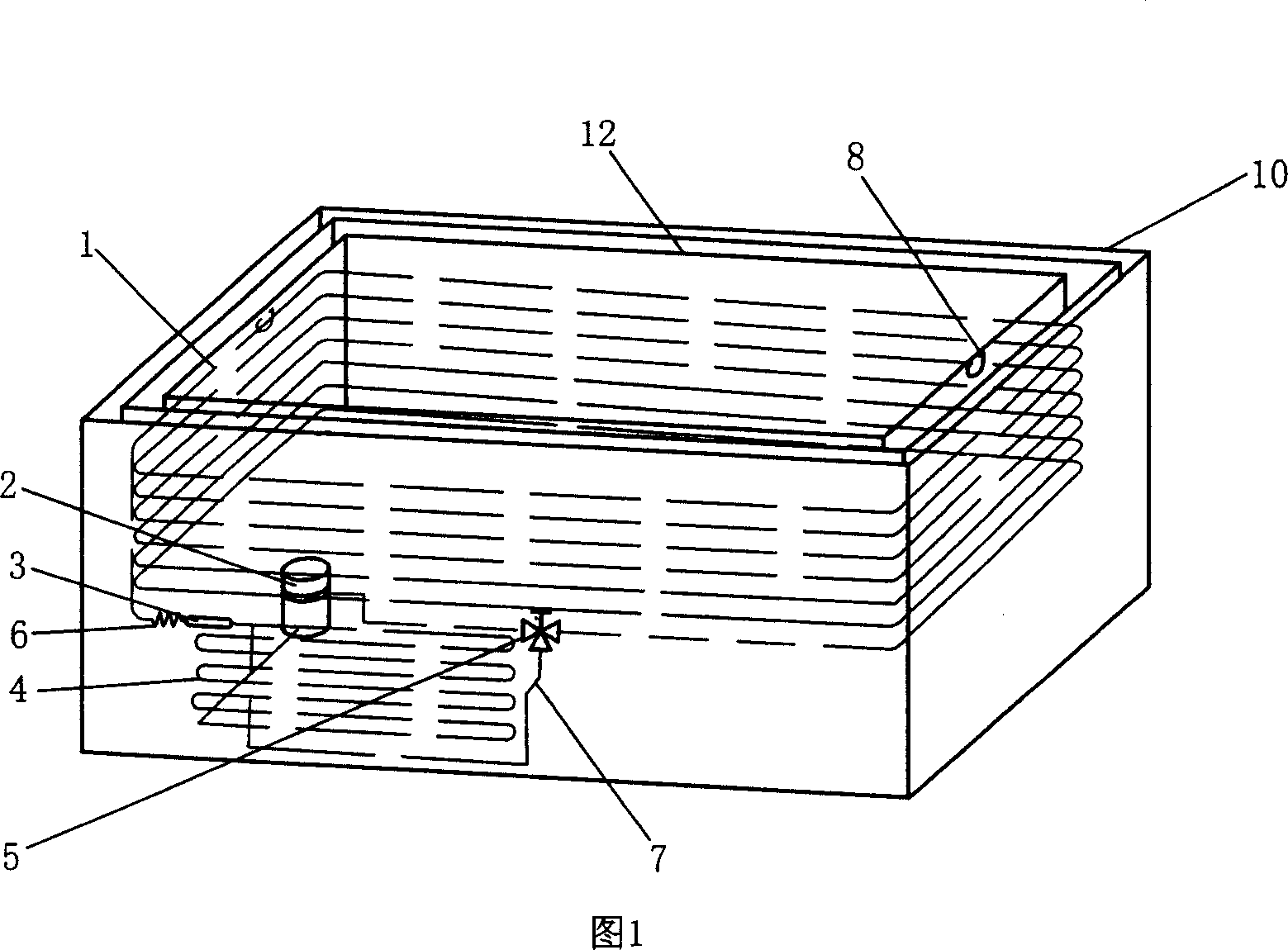

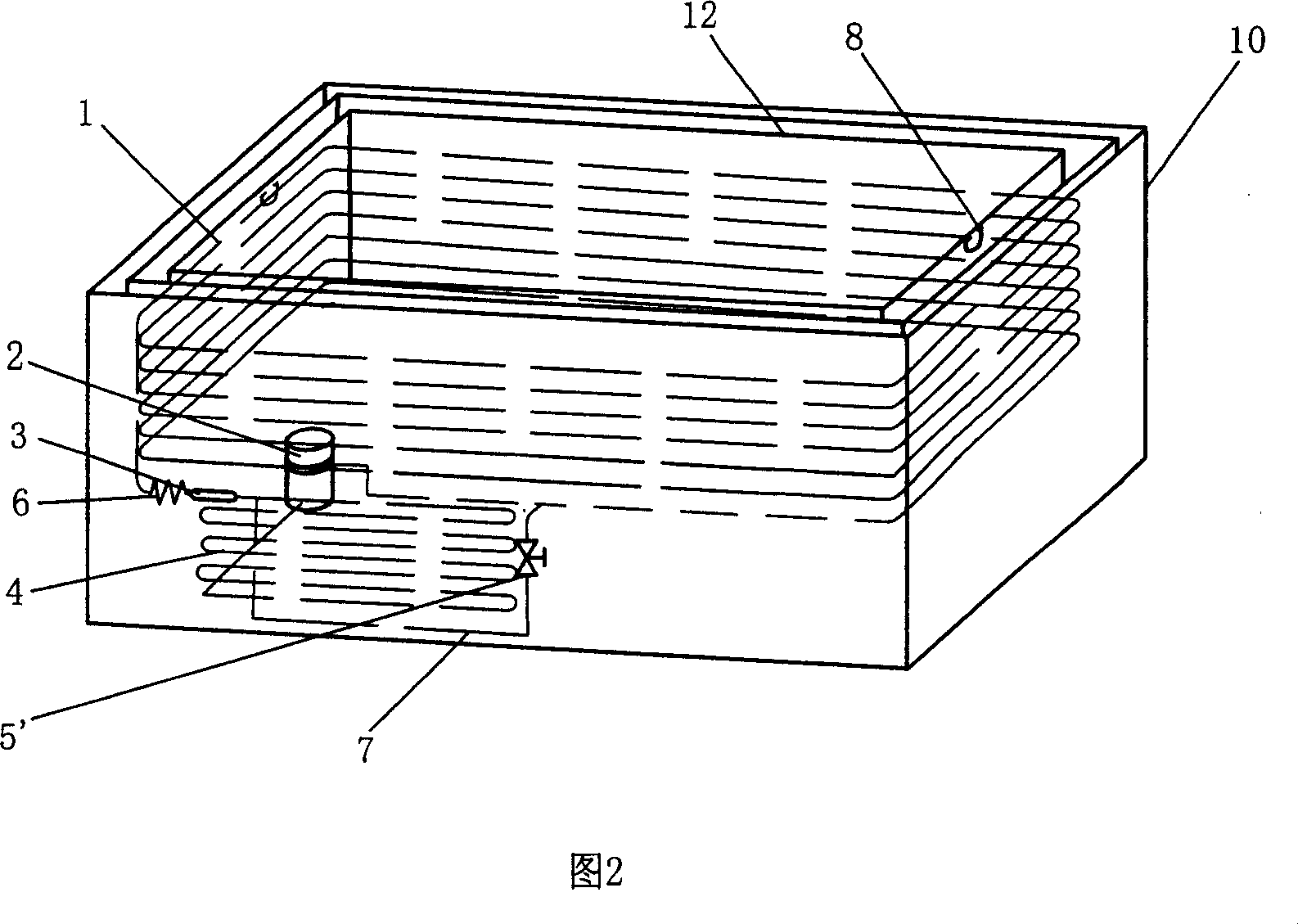

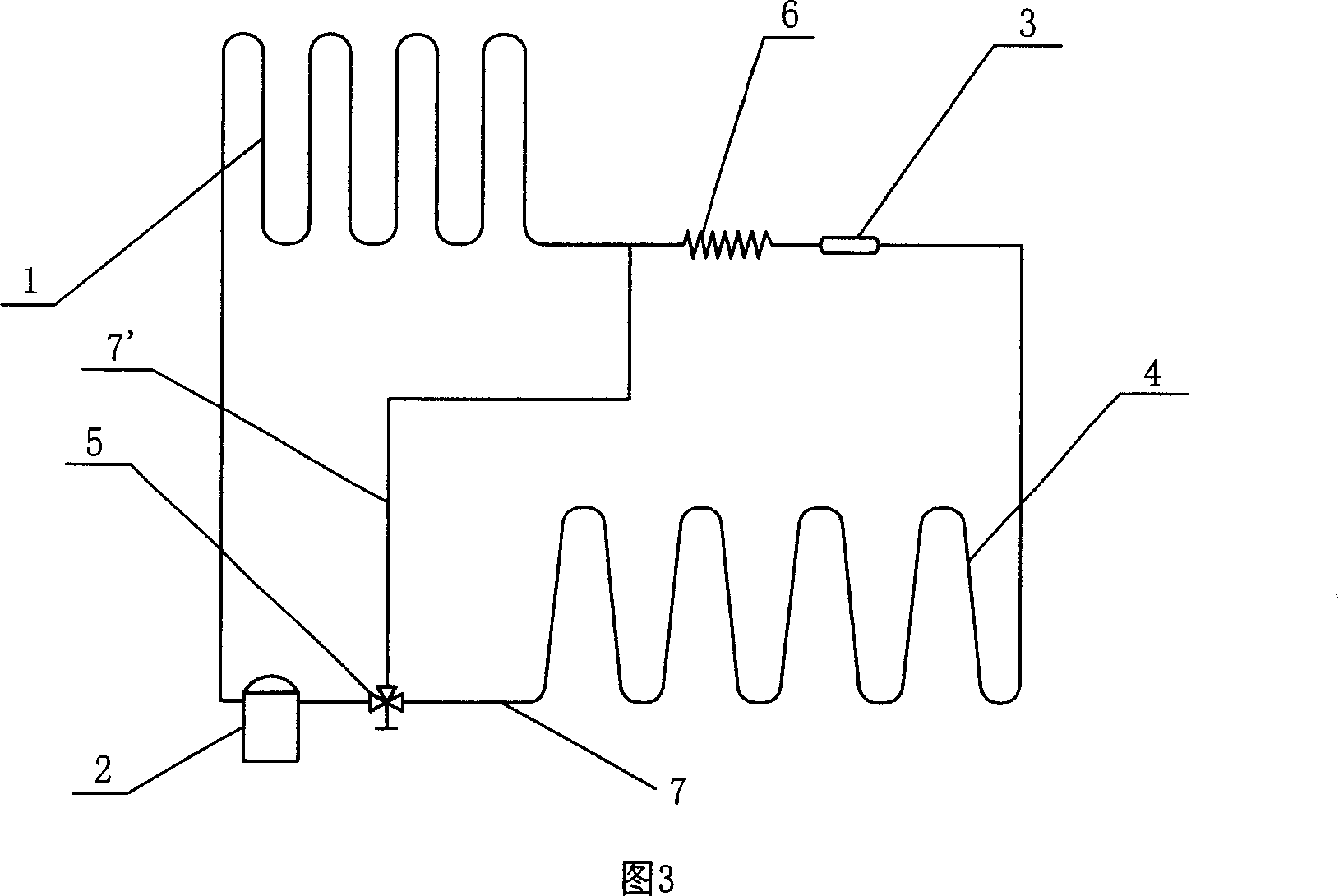

[0027] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, in the structural diagram of a horizontal freezer with defrosting function of the present invention, the upper cover of the freezer is not drawn, and its structure includes a cabinet body 10. A compressor 2 , a condenser 4 , a dry filter 3 , a capillary 6 , and an evaporator 1 are sequentially connected in series through a pipeline 7 on 10 . Its main feature is that a valve that can short-circuit the condenser 4 is connected to the pipeline 7 in which the compressor 2, the condenser 4, the dry filter 3, the capillary 6 and the evaporator 1 are connected in series.

[0028] The valve that can short-circuit the condenser 4 is arranged on the pipeline 7 in two ways.

[0029] The first embodiment is that the valve that can short-circuit the condenser 4 is a manual or electric three-way valve 5 (see Fig. 1 and Fig. 3), and the manual or electric three-way valve 5 is connected to the compressor On the pipeline 7 between the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com