Method for preparation of DC motor brushless commutator

A manufacturing method and DC motor technology, applied in current collectors, rotating current collectors, circuits, etc., can solve the problems of unusable sensing time lag, insufficient reliability of sensing units, and high cost, and achieve low cost and reduced cost , commutation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

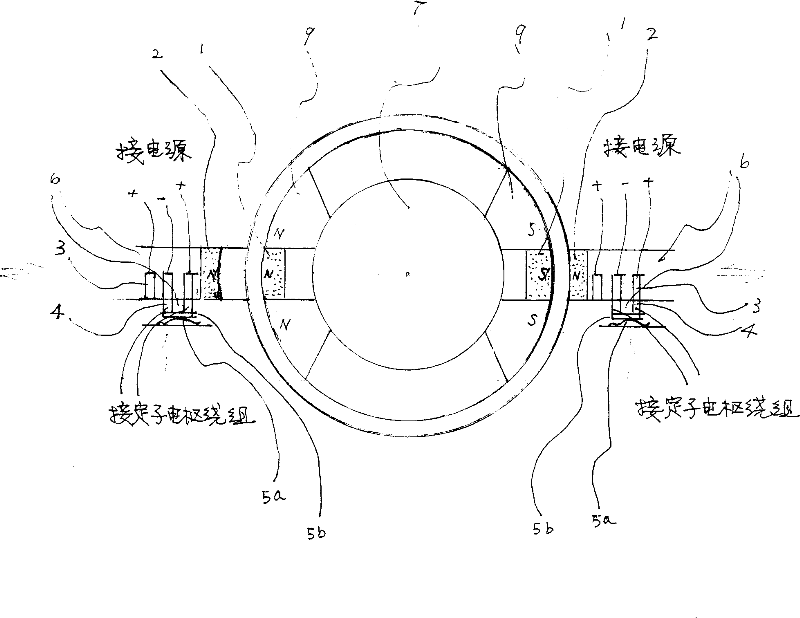

[0020] In one embodiment of the present invention, the structure of a DC motor brushless commutator is shown in Figure 1: the commutator is composed of a position sensing unit for providing correct commutation information and a position sensing unit for processing commutation information The switch unit is composed of the position sensing unit using the magnetic effect and the switch unit adopting the method of mechanical contact switch.

[0021] The position sensing unit is divided into a rotor part and a stator part, and the rotor part is composed of permanent magnets (1) located on the rotating shaft (7) with the same number and the same pole direction as the main magnetic poles (9) of the rotor (in another aspect of the present invention In one embodiment, the permanent magnet is located on the rotor), and its stator part is composed of permanent magnets (2) located on the stator and equal in number to the permanent magnets (1), and the permanent magnets (2) are opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com