Photoelectric conversion optical fiber directly connected contact box structure for online monitoring high voltage temperature

A technology of photoelectric converters and contact boxes, applied in thermometers, thermometers using directly heat-sensitive electric/magnetic components, circuit breaker testing, etc., can solve major equipment and personal accidents, dangers, etc., to achieve anti-electromagnetic Strong interference ability, reliable and convenient online monitoring, and convenient equipment modification and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

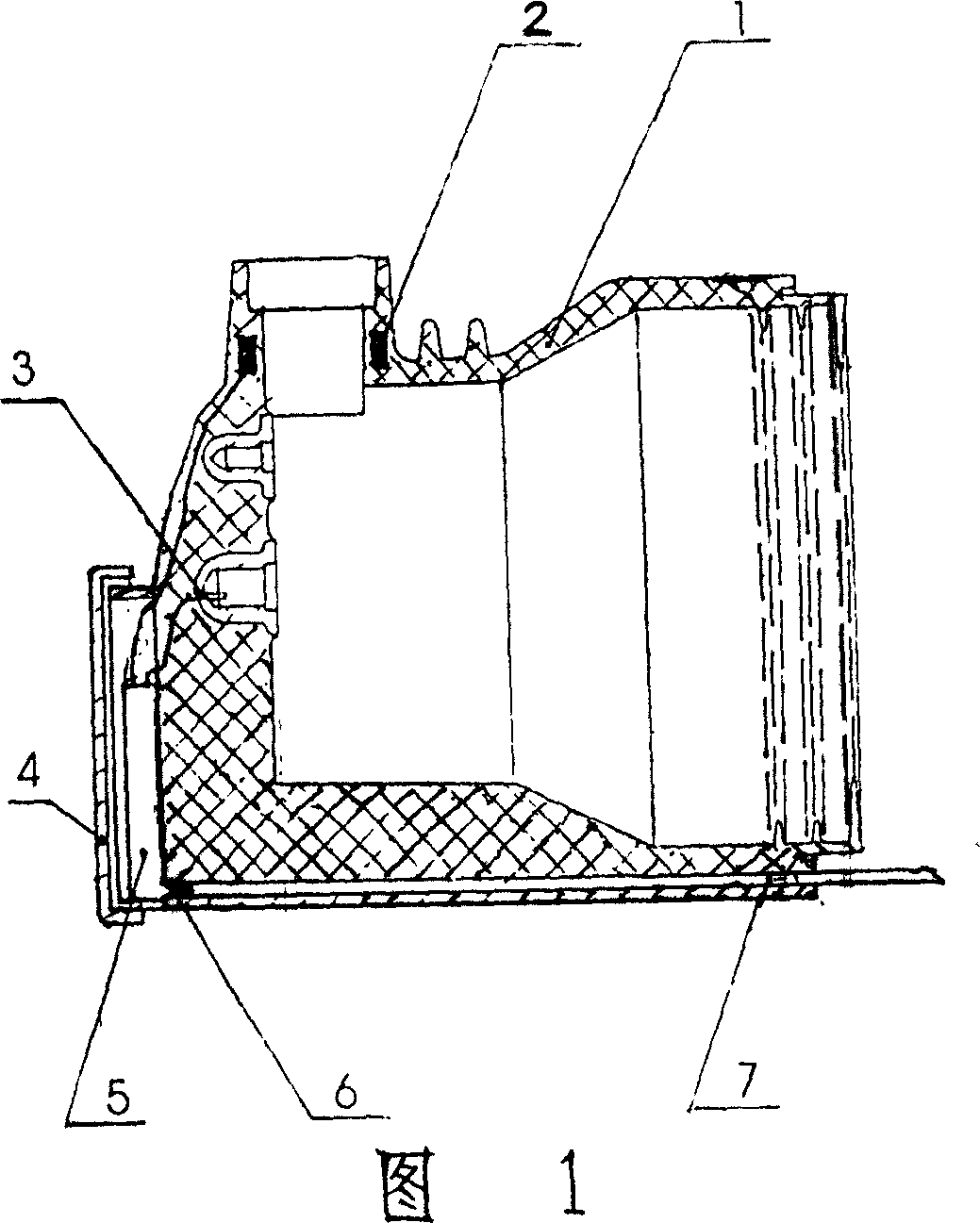

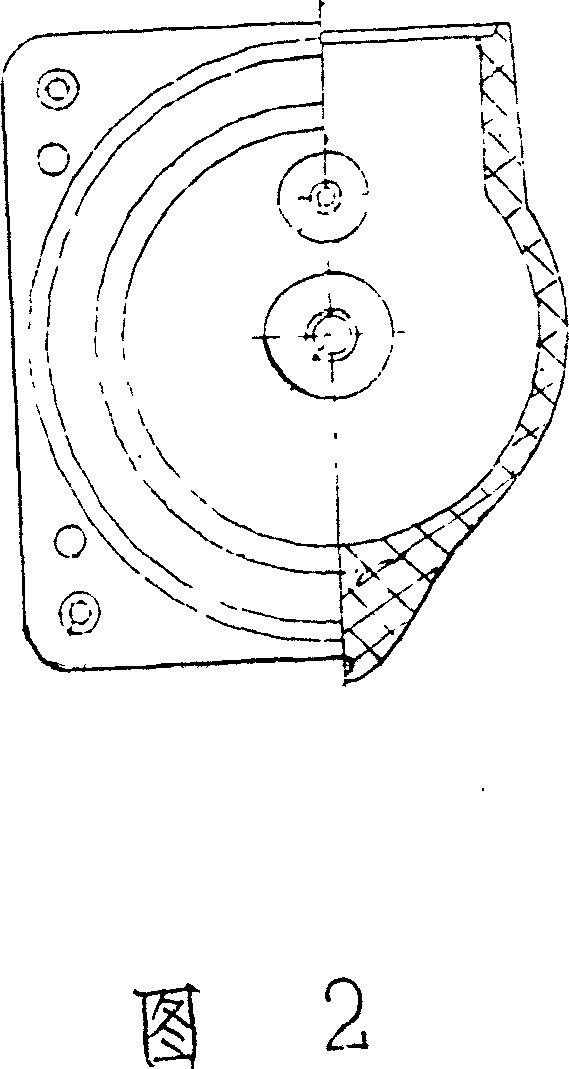

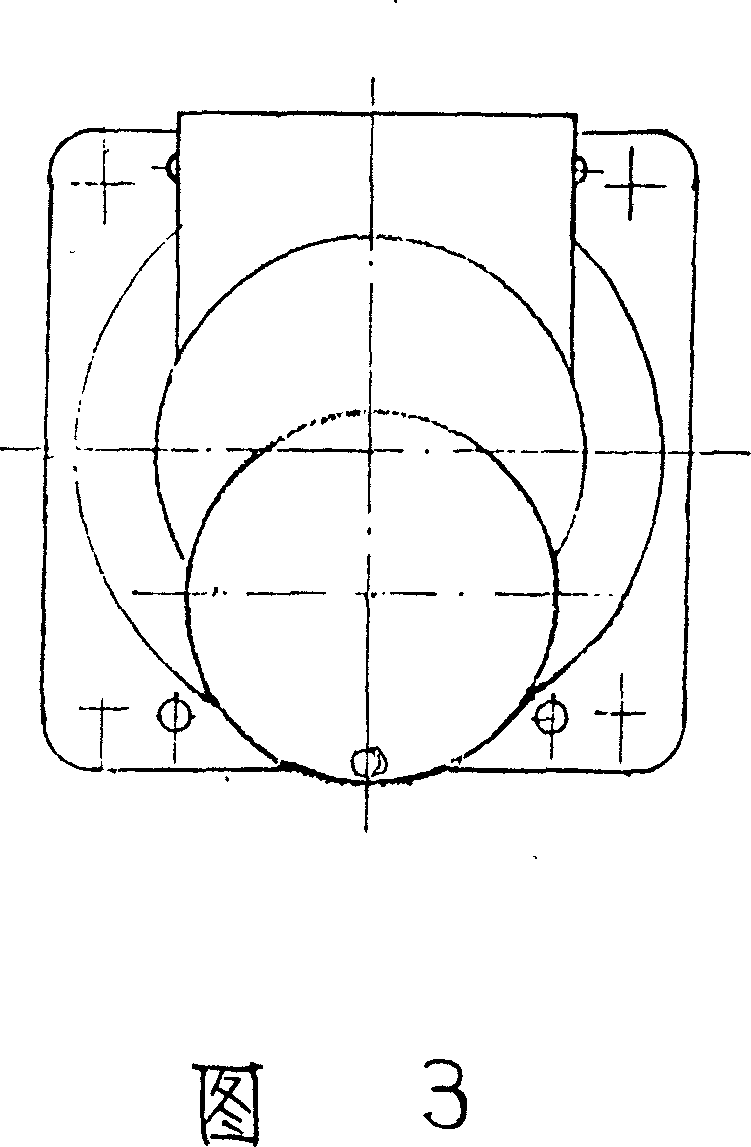

[0031] Please refer to Figure 1-Figure 3, there is a main body 1 of the contact box, a through hole is opened on the upper side of the main body 1, and the inductive power supply 2 in the insulator is injected into the inner side of the upper through hole of the main body 1, and the inductive power supply 2 passes through the lead wire Connect with the photoelectric converter 5 to provide its working power; the inner cavity of the main body 1 is embedded with a thermal detector 3 on the inner wall of the centerline position to fix the insert to detect the temperature of the static contact, and its lead wire is connected to the photoelectric converter 5 To input the temperature signal; the main body 1 is provided with a left and right transparent hole on the other side corresponding to the through hole at the upper end, and the left end of the hole is equipped with an infrared emission tube 6 connected to the photoelectric converter 5, and the infrared emission tube 6 is connecte...

Embodiment 2

[0033] Please refer to Figure 1-Figure 3 and Figure 8, there is a main body 1 of the contact box, and a through hole is opened on the upper side of the main body 1, and the inside of the upper through hole of the main body 1 is injected with the inductive power supply 2 in the insulator, the inductive power supply 2. Connect with the photoelectric converter 5 through the lead wire to provide its working power; the inner cavity of the main body 1 is fixed on the inner wall of the center line, and a thermal detector 3 is embedded in the insert to detect the temperature of the static contact. The lead wire and the photoelectric converter connected to the sensor 5 to input the temperature signal; the main body 1 is provided with a left and right transparent hole corresponding to the through hole at the side end, the left end of the hole is equipped with a side infrared emission tube 6 connected with the photoelectric transducer 5, and the infrared emission tube 6 Connect with the o...

Embodiment 3

[0035]Please refer to Figure 1-Figure 3 and Figure 9, there is a main body 1 of the contact box, and a through hole is opened on the upper side of the main body 1, and the inner side of the through hole on the upper side of the main body 1 is injected with the inductive power supply 2 in the insulator, the inductive power supply 2. Connect with the photoelectric converter 5 through the lead wire to provide its working power; the inner cavity of the main body 1 is fixed on the inner wall of the center line and embedded with a thermal detector 3 to detect the temperature of the static contact. The lead wire and the photoelectric converter connected to the sensor 5 to input the temperature signal; the main body 1 is equipped with an infrared emission tube 6 connected to the photoelectric converter 5 at the corresponding end of the upper through hole, the infrared emission tube 6 is connected to the directly embedded optical fiber 7, and the optical fiber 7 is connected to the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com