Soft polyurethane foam plastic prepared by rape oil

A flexible polyurethane and foam technology, applied in the field of flexible polyurethane foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

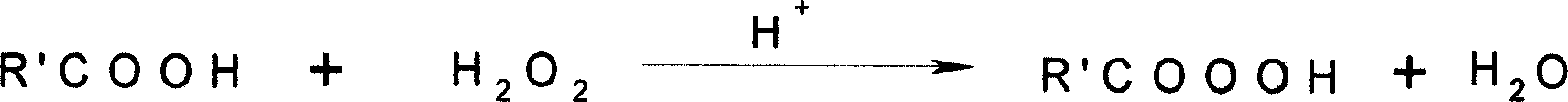

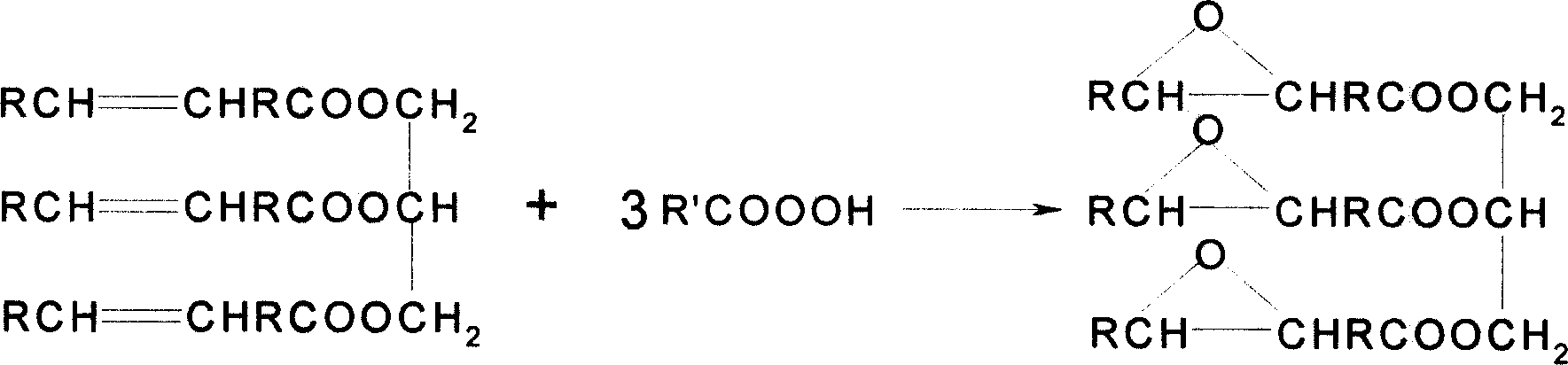

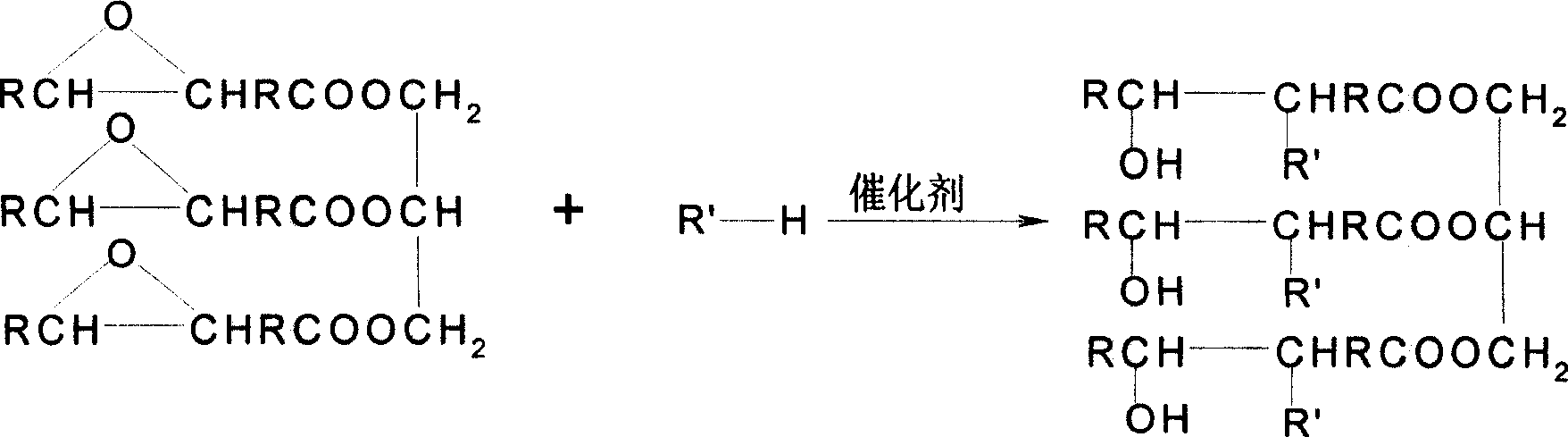

Method used

Image

Examples

Embodiment 1

[0075] 1000g of refined rapeseed oil (108 iodine value), 250g of formic acid (88%), 20g of phosphoric acid (50%) will be added in a 2L glass kettle, stirred, and 487g of 30% hydrogen peroxide is added dropwise. Under the condition of ℃, react for 5-10 hours, stand and separate the acid water, add 6% sodium carbonate solution to neutralize, then wash 3 times with water at a temperature of 70-80 ℃, depressurize, and the vacuum degree is 100 ~700kPa removes residual moisture, obtains the product epoxy rapeseed oil, the epoxy value of testing product is 5.3%.

Embodiment 2

[0077] 980g of refined rapeseed oil (102 iodine value), 490g of benzoic acid, 25g of phosphoric acid (50%) will be added in a 2L glass kettle, stirred, and 420g of 38% hydrogen peroxide is added dropwise. React at low temperature for 5-10 hours, stand and separate the acid water, add 5% sodium hydroxide solution to neutralize, then wash 3 times with water at a temperature of 70-80°C, reduce pressure, and the vacuum degree is 100-700kPa Residual moisture is removed to obtain the product epoxy rapeseed oil, and the epoxy value of the product is 5.13%.

Embodiment 3

[0079] Add 1050g of the product epoxy rapeseed oil in Example 1 into a 5L glass kettle, then add 560g of diethylene glycol, 4.9g of potassium hydroxide, stir and heat up, control the reaction temperature at 65-180°C, and the reaction time is 5-10 Hour. Add 133g of isopropanol, control the temperature at 80-150°C, carry out the alcoholysis reaction for 4 hours, and then keep it under the condition of vacuum degree of 100-750kPa for 4 hours, then extract 68g of residual alcohol, and then take a sample for analysis. The hydroxyl value is 337mgKOH / g of bio-based polyols. Dehydration is carried out for 60 minutes at a vacuum degree of 100-750KPa and a temperature of 80-120° C., and the water content is lower than 0.05% after filtration. Feed according to the order of EO and PO, wherein EO: 374g, PO: 2119g, after a reaction time of 4 to 6 hours, refine to obtain 3950g of bio-based polyether polyol A with a hydroxyl value of 56KOHmg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com