Rice cooker

A rice cooker and steam technology, applied in heating devices, cooking utensils, household appliances, etc., can solve the problems of sticky rice, dry rice, difficult steam volume, etc., and achieve the effect of preventing rice from drying out and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

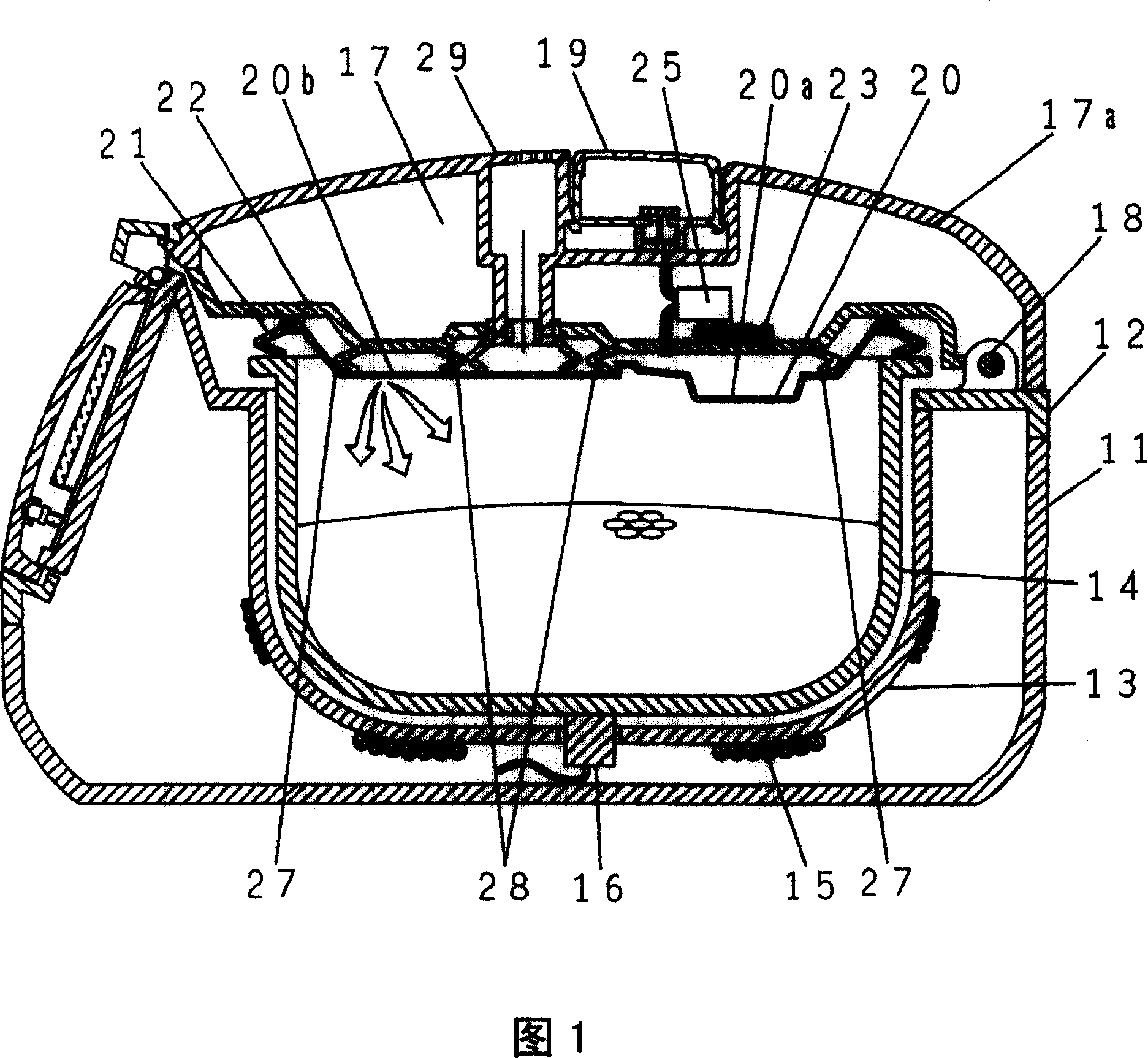

[0016] Fig. 1 shows an electric rice cooker in Embodiment 1 of the present invention.

[0017] As shown in FIG. 1 , the pot body 11 is roughly cylindrical, with an opening on its upper surface, and an upper frame 12 is inlaid on the opening. The upper frame 12 and the coil seat 13 form an accommodating cavity of the pot 14 inside the pot body 11 . The coil base 13 is formed into a bottomed cylindrical shape, and its upper end is fixed to the upper frame 12 . In addition, a pan bottom induction coil for inductively heating the pan 14 is provided on the coil base 13 to form a pan heating device 15 for inductively heating the pan 14 .

[0018] The pot bottom sensor 16 used to detect the temperature of the pot 14 is installed to withstand the bottom surface of the pot 14 by elastic force, and detects the temperature of the pot when cooking and keeping warm, so as to keep the cooking material in the pot 14 at the optimum temperature superior.

[0019] The pot cover 17 is support...

Embodiment 2

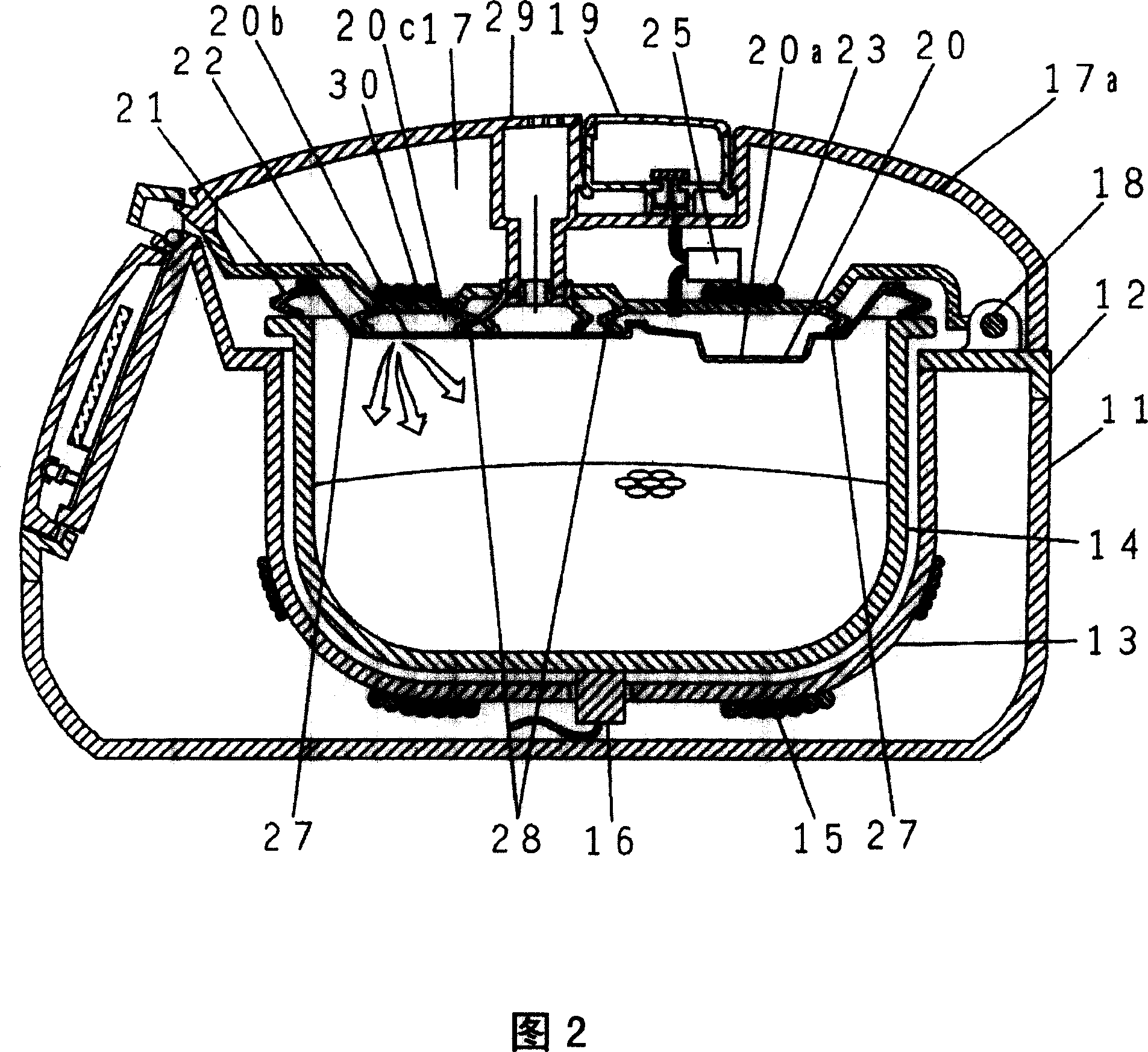

[0033] Fig. 2 is the electric rice cooker in the embodiment 2 of the present invention. Wherein, for the same constituent elements as those in Embodiment 1, only the same symbols are marked here, and repeated descriptions thereof are omitted, and the descriptions are focused on the differences.

[0034] As shown in FIG. 2, a steam heating unit 20c is provided in the electric rice cooker of Embodiment 2 for increasing the temperature of the steam generated in the steam generating unit 20a on the cover heating plate 20, at the corresponding position of the steam heating unit 20c. A second lid heating device 30 is also provided at the position. The second lid heating device 30 is controlled by a second lid heating control device (not shown).

[0035] The operation and effect of the electric rice cooker having the above-mentioned constitution will be described below.

[0036] When cooking rice, the user first loads rice and water into the pot 14, and prepares a specified amount ...

Embodiment 3

[0040] Embodiment 3 of the present invention will be described below with reference to FIG. 1 and FIG. 2 .

[0041] In the rice cooker of the present embodiment, the steam generating unit 20a for storing the water supplied from the water container 19 and generating steam is arranged so that the steam generating unit 20a is positioned between the pivot shaft 18 supporting the lid 17 and the steam generating unit 20a. It is at a position between the steam injection port 20b communicating with the inside of the pot 14.

[0042] When cooking rice, the user first loads rice and water into the pot 14, and prepares a specified amount of water in the water container 19, then puts the pot 14 and the water container 19 in the rice cooker, and turns on the power of the rice cooker; then, Press the rice cooking start button to perform the rice cooking operation, and enter the heat preservation step after the rice cooking operation is completed. During the heat preservation process, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com