Oscillating piston engine

一种活塞式发动机、回转运动的技术,应用在旋转活塞式发动机、摆动活塞式发动机、摆动活塞式发动机等方向,能够解决活塞延迟、运行平稳性不利影响、不能到达UT位置等问题,达到运行平稳性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

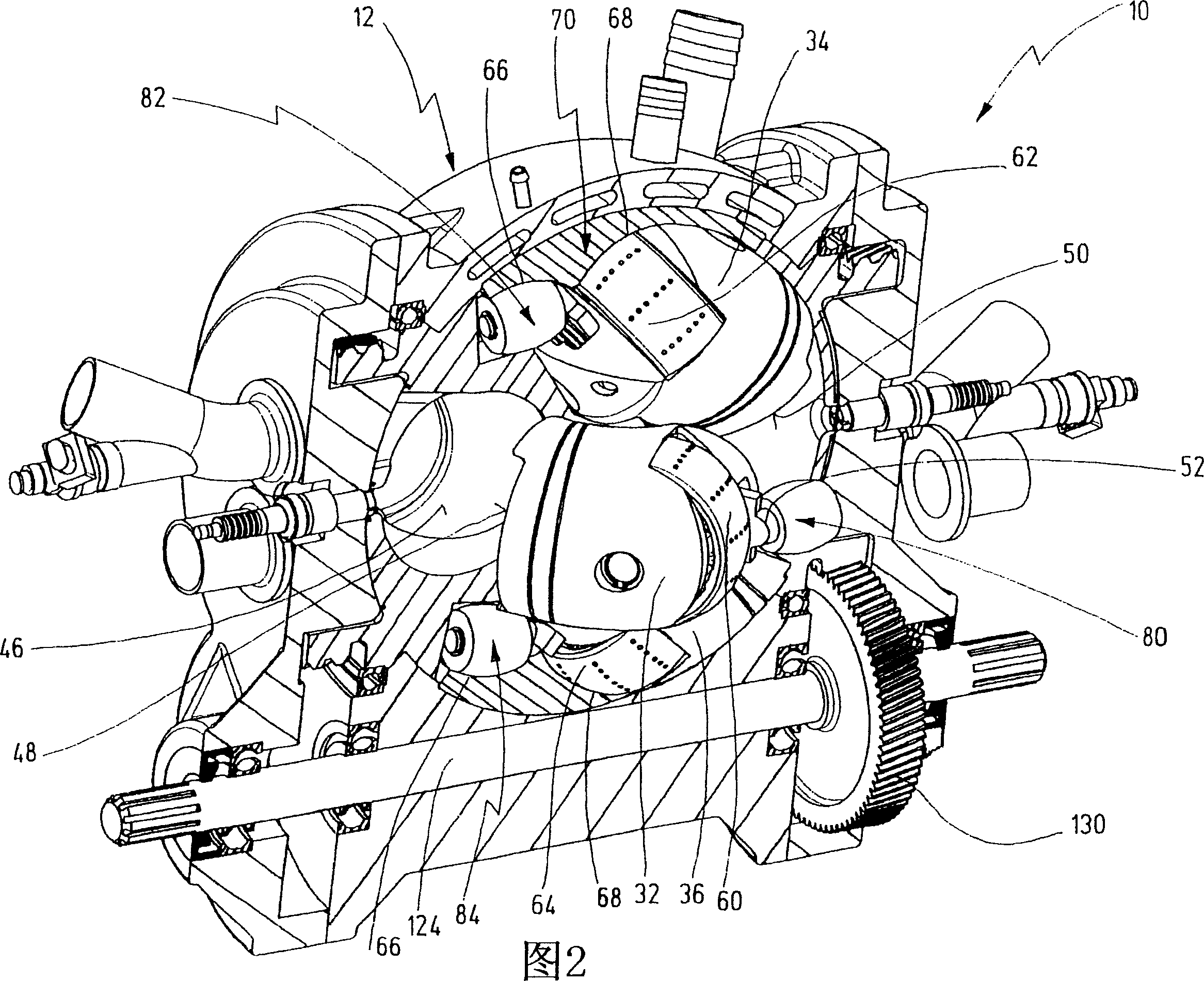

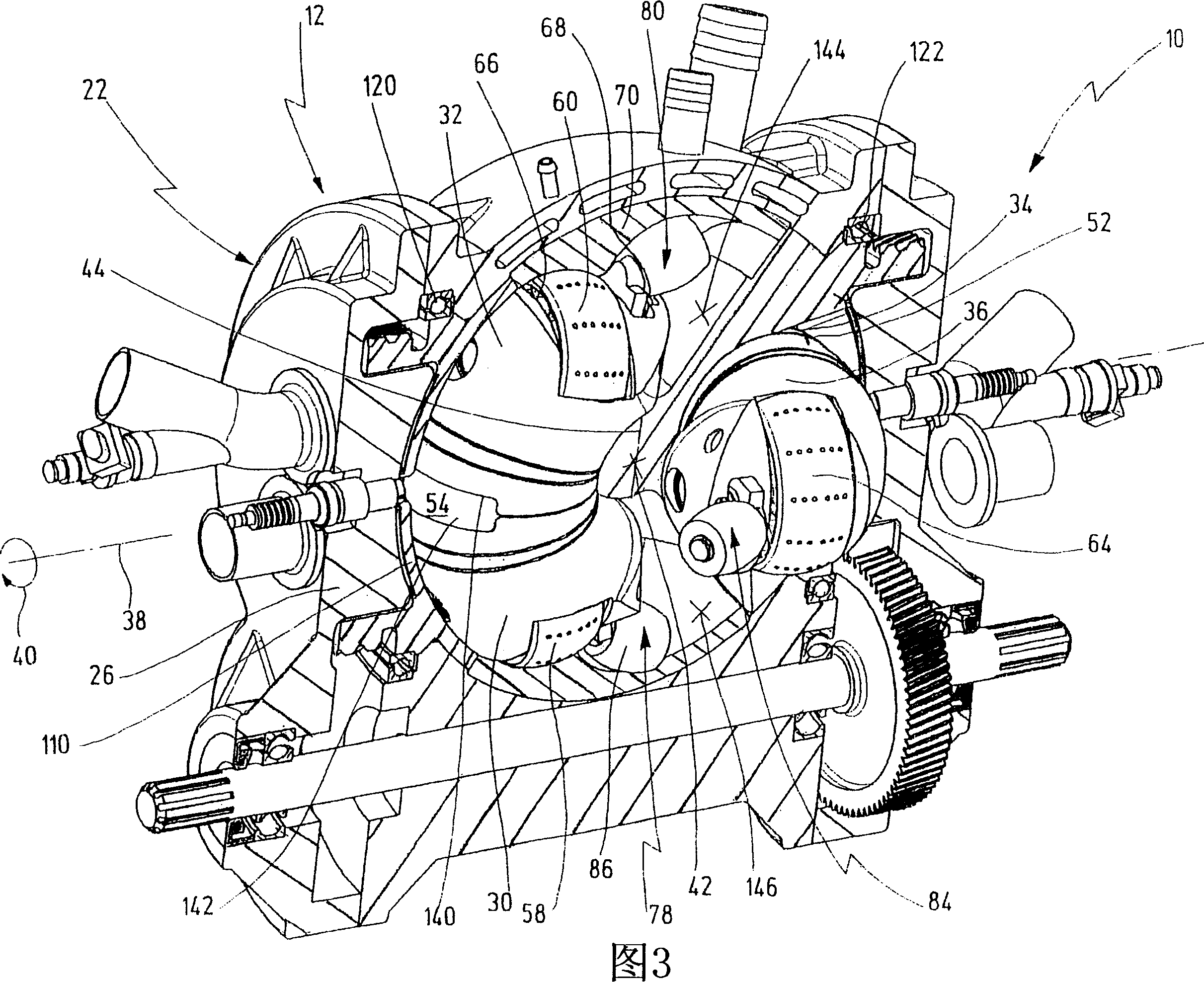

[0042] Figures 1-4 show a rotary piston engine generally indicated at 10 . Additional details of the rotary piston engine 10 are shown in Figures 5-10.

[0043] The rotary piston engine 10 is configured as an internal combustion engine as a whole, but it can also be used as a pump or a compressor after corresponding changes.

[0044] The rotary piston engine 10 has a housing 12 shown closed in FIG. 1 . The housing 12 has a spherical central housing section 14 . The central housing section 14 is composed of two half housings 16 and 18 which are connected to one another via a flange 20 .

[0045] The housing 12 also has a first end face 22 and a second end face 24 opposite the first end face 22 .

[0046] The first end face 22 is formed by an end-face housing cover 26 and the second end face 24 is formed by an end-face housing cover 28 . The housing covers 26 and 28 are connected to the central housing section 14 or its two half housings 16 and 18 . The housing covers 26 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com