Preparing method of composite catalytic solid-phase prepared hydroxypropyl starch

A technology for the preparation of hydroxypropyl starch and solid phase, which is applied in the field of preparation of hydroxypropyl starch and its preparation, achieving obvious economic benefits, no pollution to the environment, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

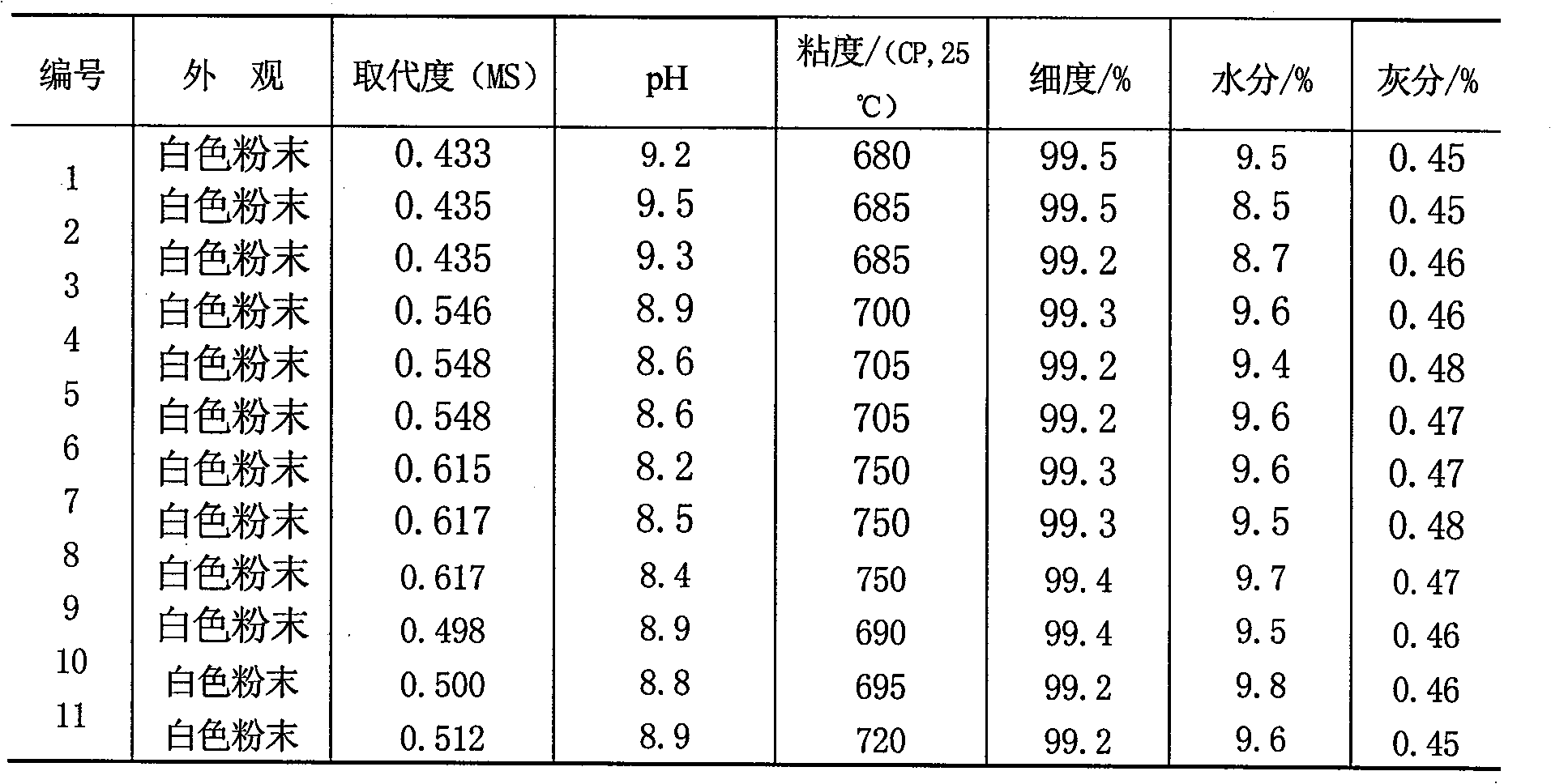

Examples

Embodiment 1

[0025] In a 40-liter sealed reactor with stirring device, thermometer, pressure gauge and pressure reducing valve, add 10kg of cornstarch and 1.5kg of 20% aqueous sodium hydroxide solution, stir at room temperature for 20min, then add 0.6kg of fatty alcohol polyoxyethylene Ether, continue stirring at room temperature and mix evenly (about 10min), then add 2.5kg 1,2-propylene oxide, seal the reactor, and stir to react. During the reaction, adjust the stirring speed to keep the reaction temperature at 80°C-85°C, and the pressure in the reactor at 0.3-0.7MPa. Stir the reaction for 50 minutes. At this time, increase the stirring speed, and the pressure in the reactor does not increase, which proves that the reaction is complete. After the reaction, the pressure in the reactor was released to obtain 12.3 kg of basically dry white powdery hydroxypropyl starch, the water content of the product was 12%, and the molar degree of substitution MS=0.21.

Embodiment 2

[0027] In a 40-liter sealed reactor with a stirring device, a thermometer, a pressure gauge and a pressure reducing valve, add 10kg of cornstarch and 2.5kg of 20% aqueous sodium hydroxide solution, stir and react at room temperature for 20min, then add 0.8kg of fatty alcohol polyoxyethylene Ether, continue to stir and mix at room temperature (about 10min), then add 7.0kg 1,2-propylene oxide, seal the reactor, and stir for reaction. During the reaction, adjust the stirring speed to keep the reaction temperature at 80°C-85°C, and the pressure in the reactor at 0.3-0.7MPa. Stir the reaction for 50 minutes. At this time, increase the stirring speed, and the pressure in the reactor does not increase, which proves that the reaction is complete. After the reaction, the pressure in the reactor was released to obtain 14.5 kg of basically dry white powdery hydroxypropyl starch, the water content of the product was 14%, and the molar degree of substitution MS=0.46.

Embodiment 3

[0029] The product of Example 2 is used in the food industry, soaked in 75% alcoholic aqueous solution, neutralized with glacial acetic acid, washed to pH 7-8, filtered and dried to obtain pure white powdered hydroxypropyl starch, according to the food industry Determination of the use requirements to make it meet the use standards of the food industry, used for food thickeners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com