Elevator controller

A control device and elevator technology, which is applied in the field of elevator control devices, can solve problems such as the vibration of the car, the decrease of the gain of the winch, and the deterioration of the car ride, so as to speed up the change of the speed, suppress the lateral vibration, and prevent the ride. the worsening effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

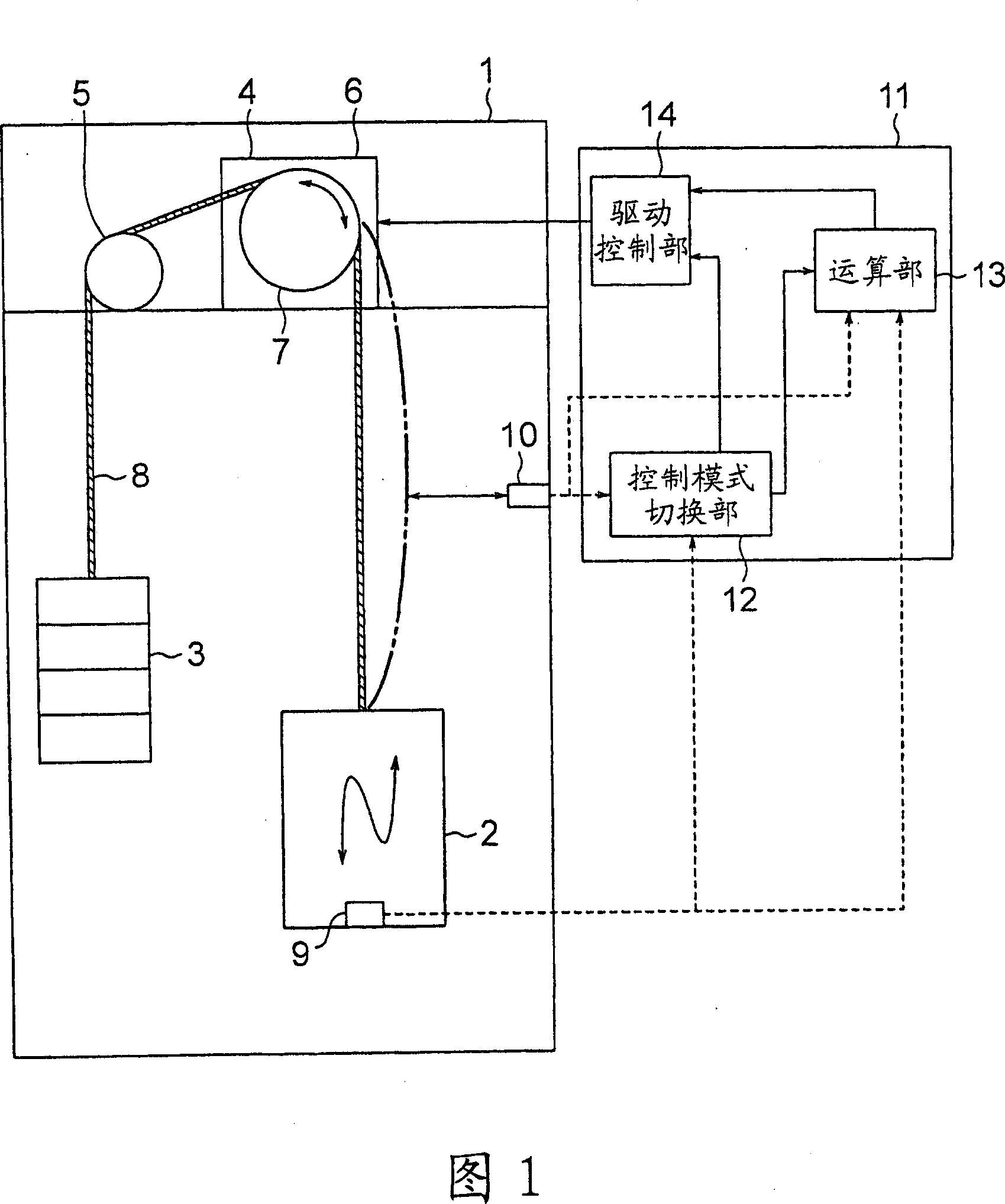

[0013] Fig. 1 is a configuration diagram showing an elevator control device according to Embodiment 1 of the present invention. In FIG. 1 , a car 2 and a counterweight 3 are provided in a hoistway 1 so as to be movable up and down. A hoist (drive device) 4 and a deflector pulley 5 for raising and lowering the car 2 and the counterweight 3 are provided on the upper portion of the hoistway 1 .

[0014] The hoist 4 has a hoist main body 6 including a motor, and a drive pulley 7 that is rotated by the hoist main body 6 . A plurality of main ropes (moving connectors) 8 are wound on the driving pulley 7 and the deflecting pulley 5 . The car 2 and the counterweight 3 are suspended in the hoistway 1 by respective main ropes 8 . One end of each main rope 8 is connected to the upper portion of the car 2 , and the other end of each main rope 8 is connected to the upper portion of the counterweight 3 .

[0015] The car 2 is provided with a car vibration measuring device 9 for measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com