Liquid container

A liquid container, liquid containment technology, applied in instruments, volume measurement instruments/methods, liquid/fluid solid measurement, etc., can solve the problem that the flexible film cannot track the volume change of the liquid detection chamber smoothly, the flexible film cannot be easy, and the cost of the liquid container Problems such as rising, to achieve the effect of not easy to deform, prevent cost increase, and shrink volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

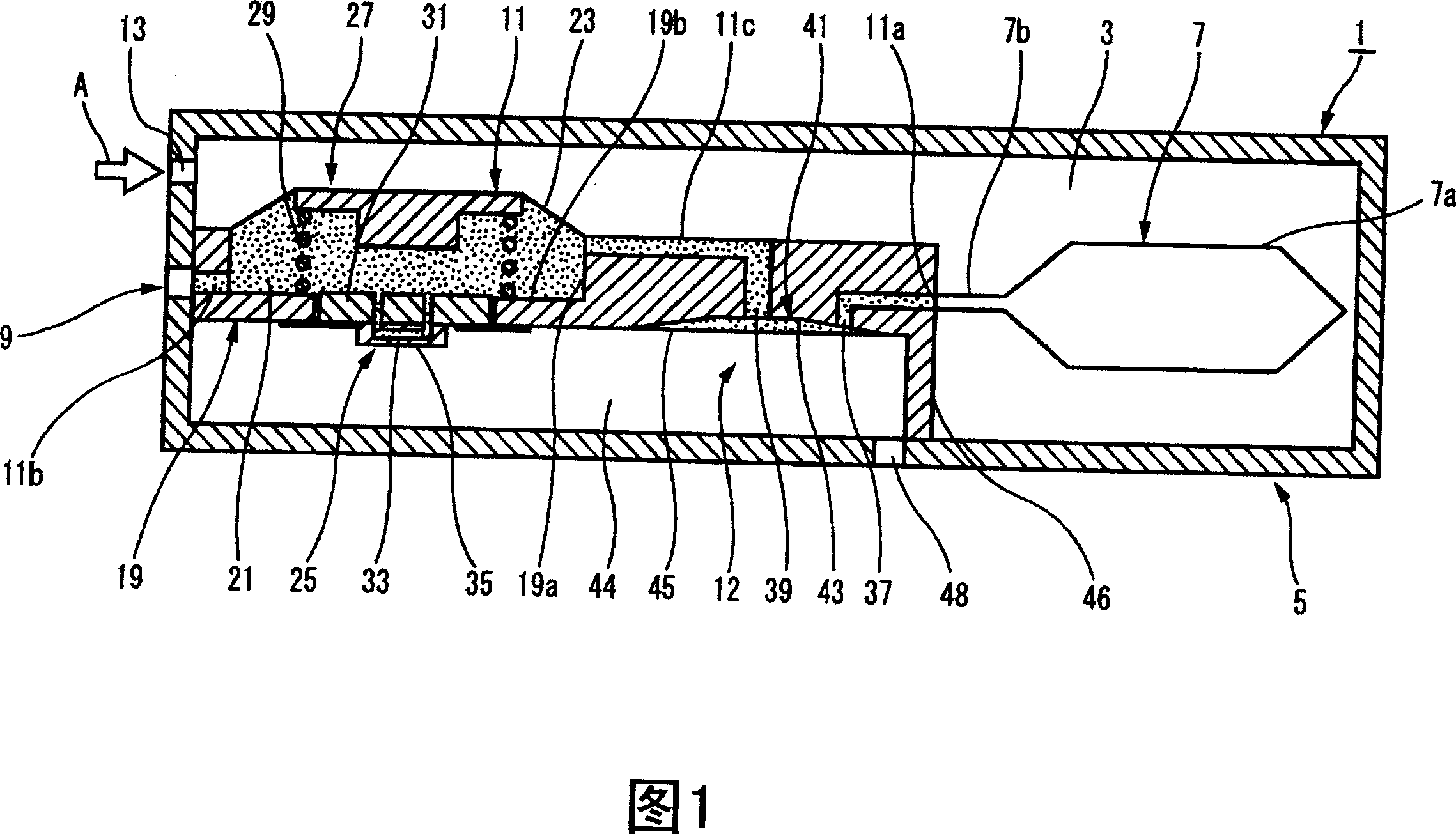

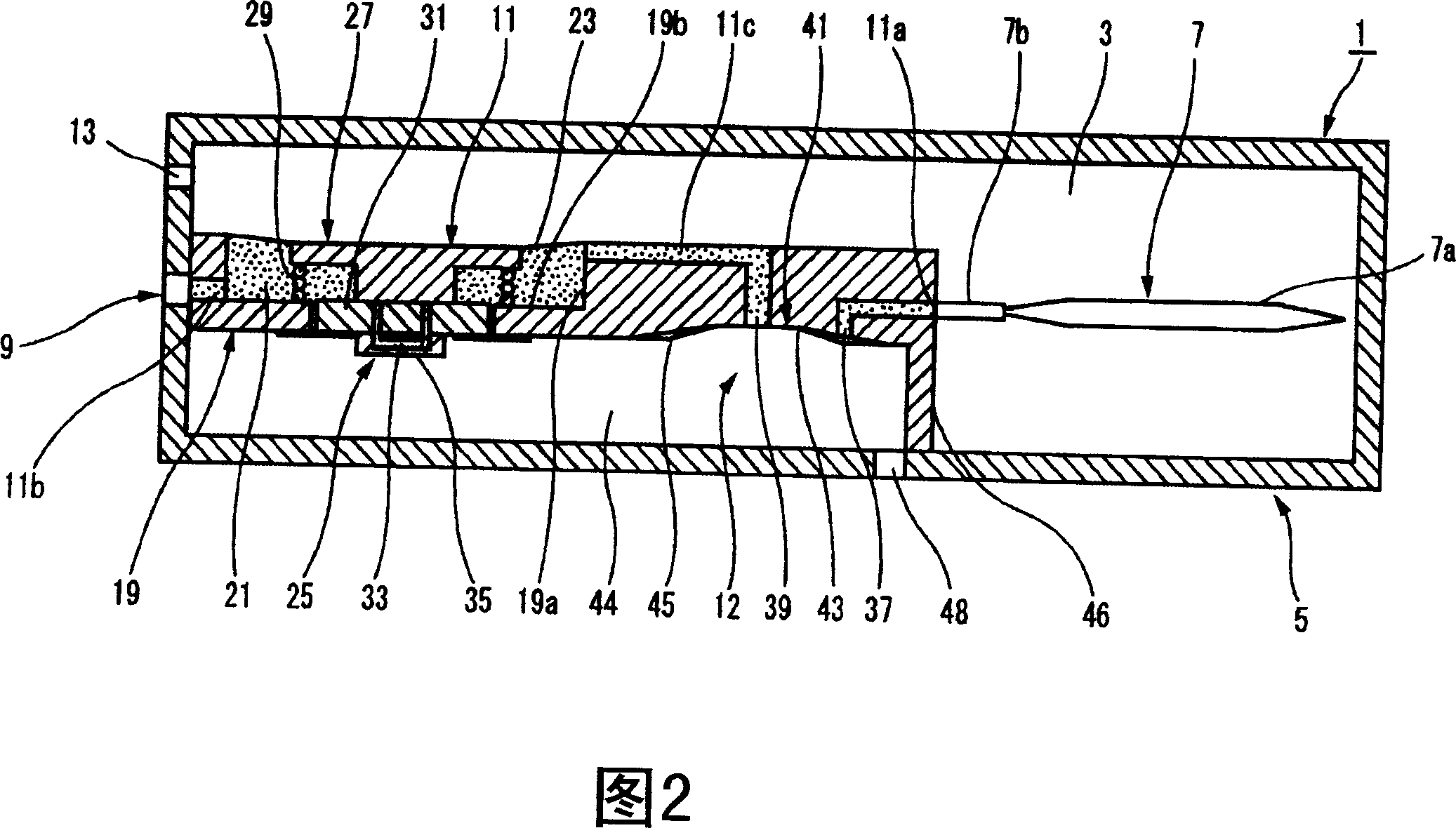

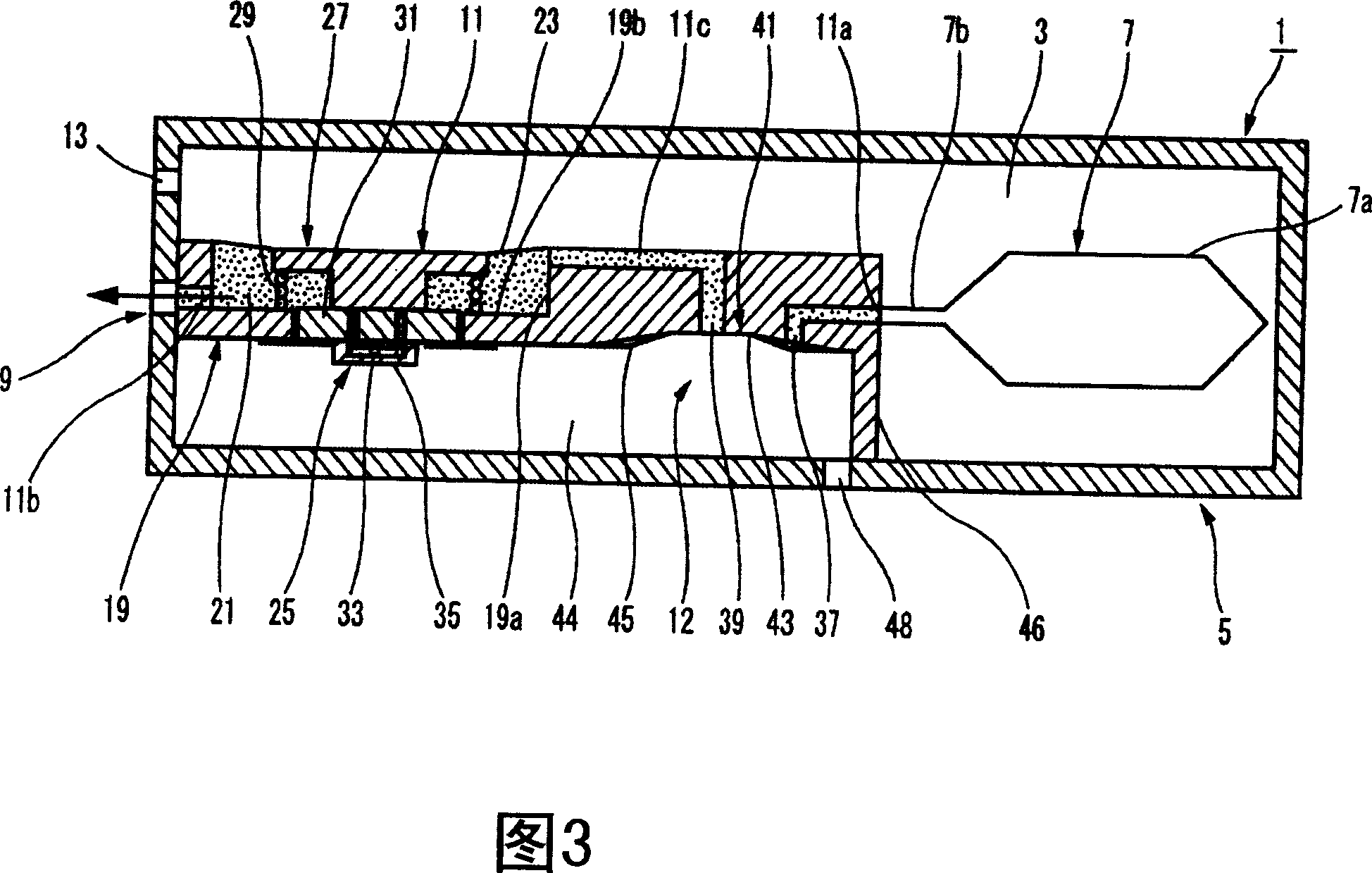

[0046] Hereinafter, preferred embodiments of the liquid container of the present invention will be described in detail with reference to the drawings.

[0047] 1 is a longitudinal sectional view of a liquid container according to a first embodiment of the present invention, showing a state in which a liquid capacity of a liquid detection chamber is equal to or greater than a predetermined amount. 2 is a longitudinal sectional view of the liquid container shown in FIG. 1 when the inflow port and the outflow port are closed, and FIG. 3 is a longitudinal sectional view of the liquid container in a virtual liquid-depleted state with the opening and closing valve mechanism closed.

[0048] The liquid container 1 of the first embodiment is an ink cartridge that is detachably mounted on a cartridge mounting portion of an inkjet recording device (liquid consuming device) The head supplies ink (liquid).

[0049] As shown in Figure 1, the liquid container 1 includes: a container body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com