Yarn feeding device

A technology of yarn feeding device and adjusting device, which is applied in transportation and packaging, thin material handling, textiles and paper making, etc. It can solve the problems of individual yarn tension, achieve good yarn control, precise yarn tension, and ensure yarn separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

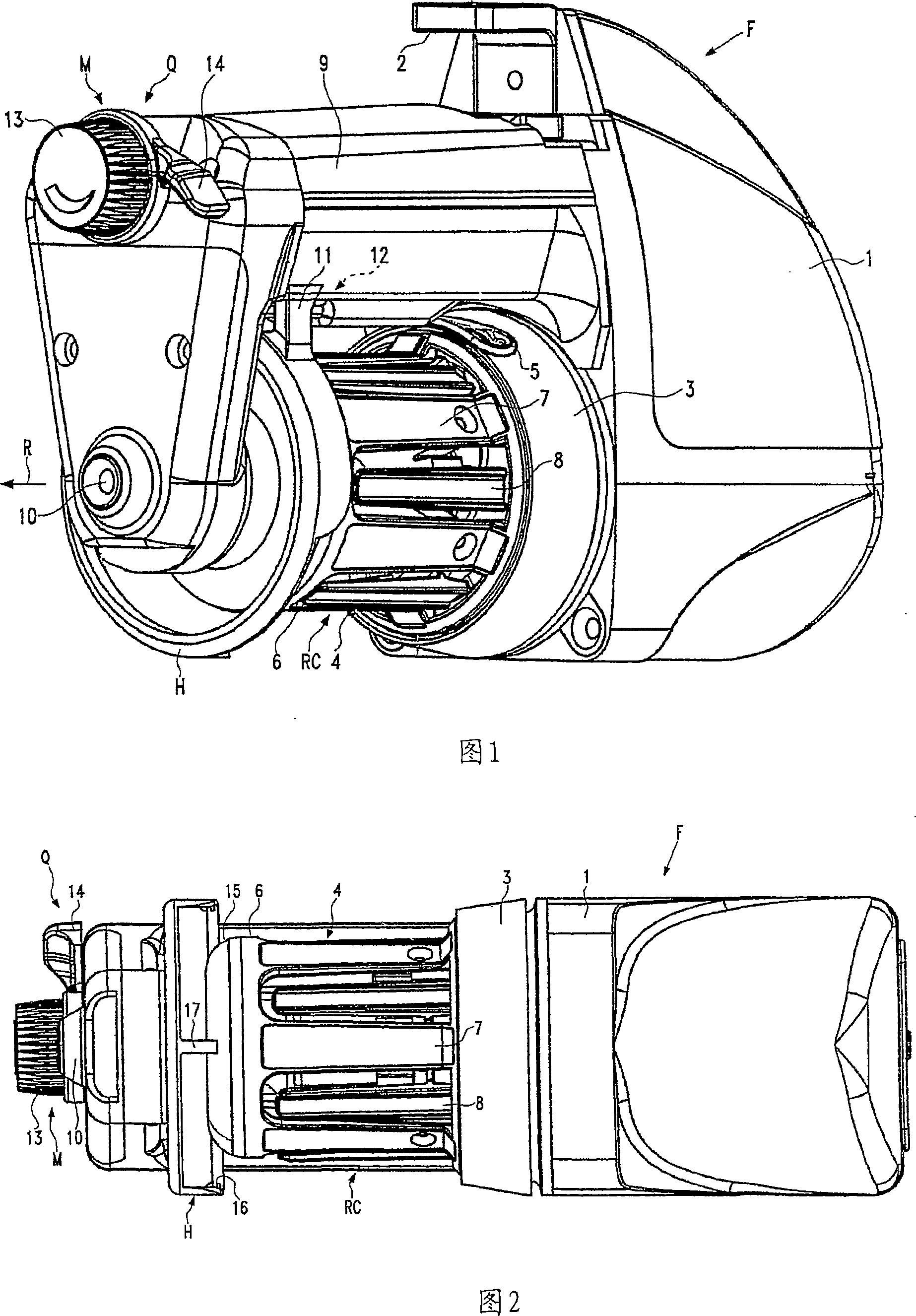

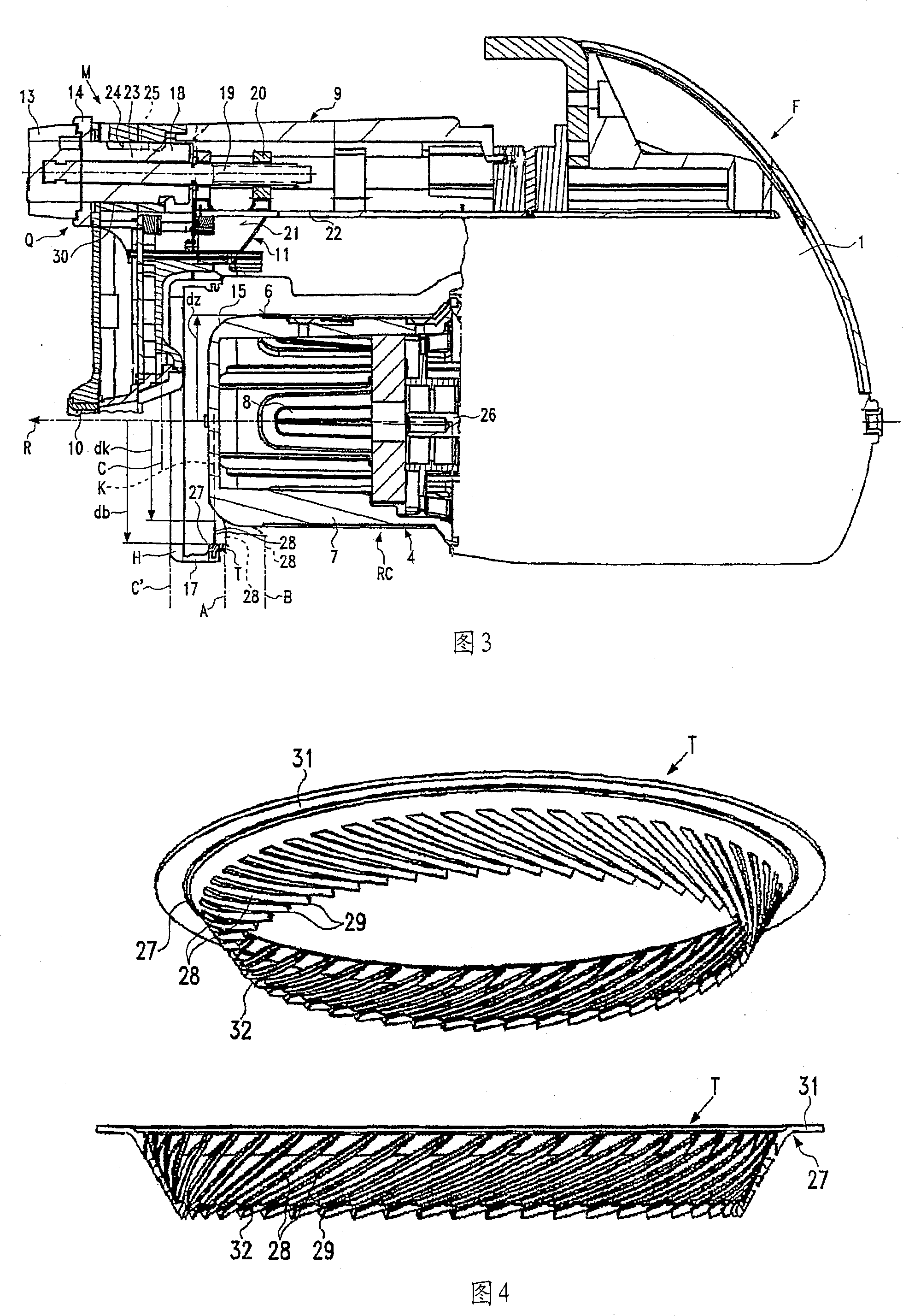

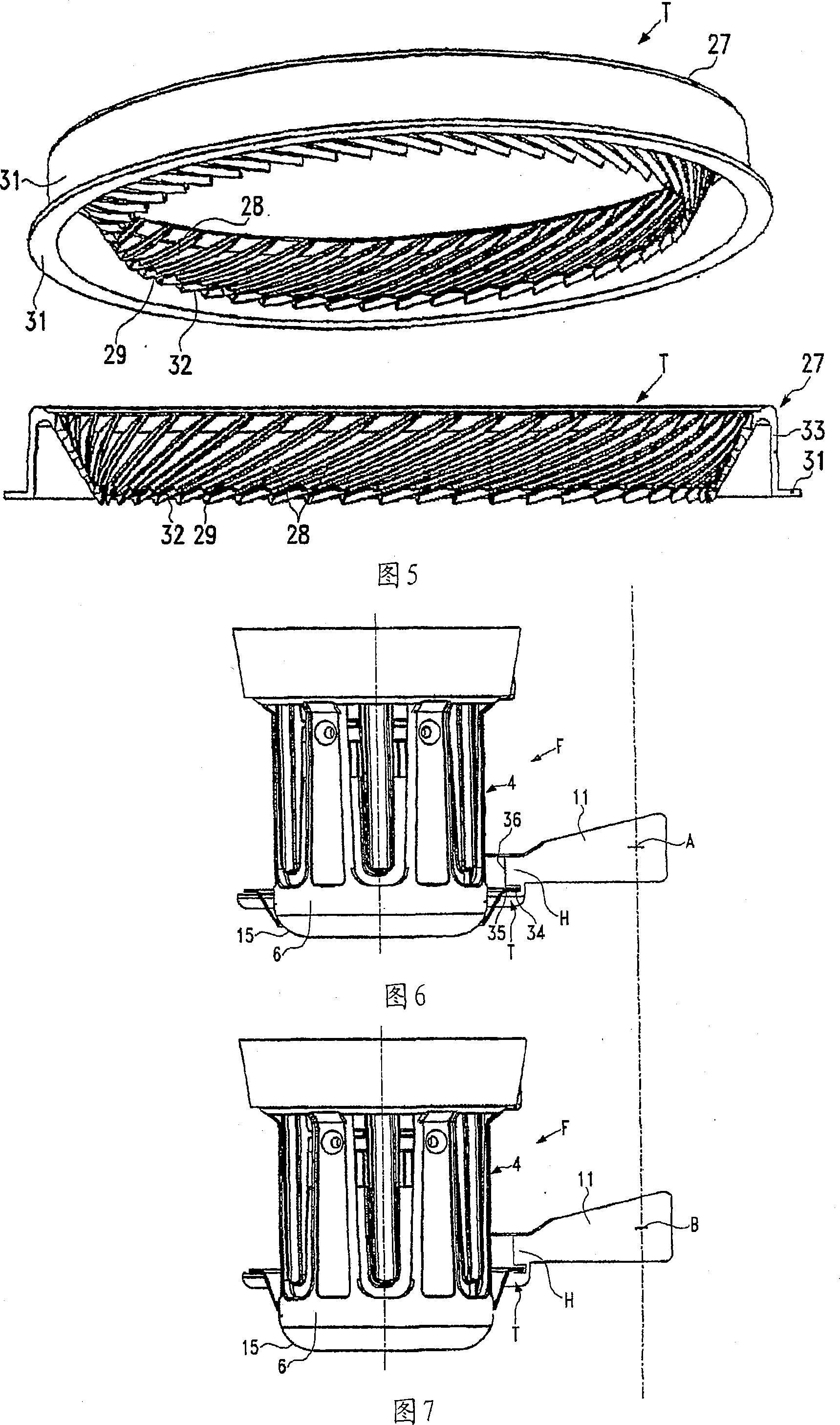

[0030]A yarn feeding device F usable for different types of knitting machines, as shown in Figures 1 to 3, comprises a housing 1 of consolidation 2, a rotatably driven winding unit 3 comprising yarn eyelets 5 and an opposite The yarn storage body 4 fixed on the winding unit 3. The yarn storage body 4 is drum-shaped and has a front cylindrical front end 6 in the unwinding direction, a front unwinding unwinding rim 15 which is circular in this embodiment, and a cylindrical Rod cage structure RC between front end 6 and winding unit 3 . Said rod cage structure RC comprises conveying rods 7 equidistantly distributed in the circumferential direction, and the conveying rods 7 are uninterrupted at least through their edges into the cylindrical front end 6 . A separating rod 8 is provided between the transport rods 7 , which can be driven due to the swinging separating movement. The separating movement of the separating lever 8 originates from an inclined rotatable bearing on the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com