Binding element and plurality of binding elements particularly suited for automated processes

A technology of components and ridges, applied in folders, printing, etc., can solve the problems of not easy to pack tightly, unable to book pages, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

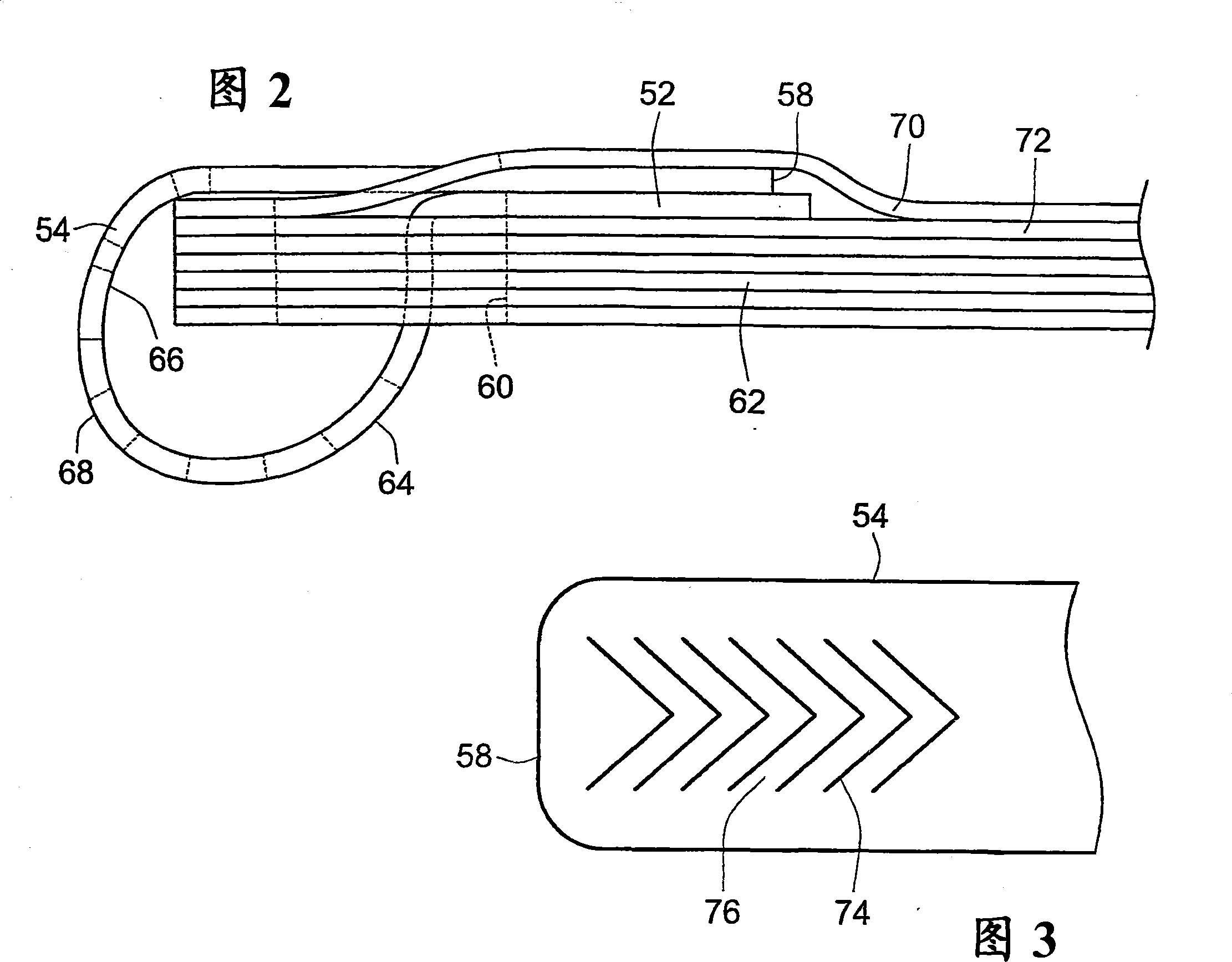

[0059] Referring to the drawings, Figure 1 illustrates a binding element 50 constructed in accordance with the teachings of the present invention. Binding element 50 includes a spine 52 from which a plurality of fingers 54 extend along an edge 56 . As shown in FIG. 2 , when assembled into a stack 62 of perforated sheets, the distal ends 58 of the fingers 52 are inserted into the apertures 60 and the distal ends 58 of the fingers 54 are coupled to the spine 52 to form a hole through the stack 62 of sheets. The closed loop 64. Binding element 50 includes an inner surface 66 and an outer surface 68 . Notably, in the presently preferred assembly of binding element 50 , the inner surface 66 of the distal end 58 of the fingers 54 is disposed on the inner surface 66 of the spine 52 , as shown in FIG. 2 . Thus, each loop portion 64 for a binding element 50 projects outwardly from one edge 56 of the spine 52 . In this way, the spine 52 together with the distal ends 58 of the fingers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com