Method for lowering multi-wing centrifugal fan noise

A centrifugal fan, fan technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of product quality optimization, high cost, long product development cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0028] 1. Among similar fan products, a multi-blade centrifugal fan produced by a certain factory that meets the national performance indicators is used as a model fan.

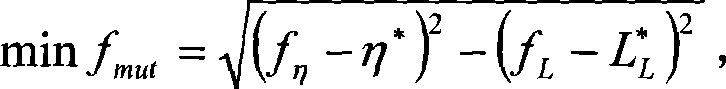

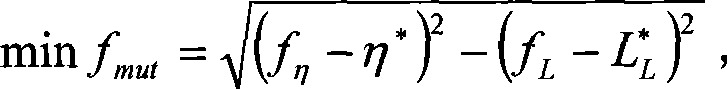

[0029] 2. First, carry out computational fluid dynamics numerical simulation on the model fan, and establish the fan impeller model: impeller outer diameter D 2 =240mm, wheel diameter ratio D 1 / D 2 =0.85, the included angle between the tangent line of the midpoint of the blade and the center of the impeller θ=35.74°, the inlet installation angle β 1 =90°, outlet installation angle β 2 = 154°, the blades are straight blades with a single arc th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com