Continuous dyeing supercritical fluid system and process

A supercritical fluid and production system technology, which is applied in dyeing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of continuous production and incapable of large batches, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

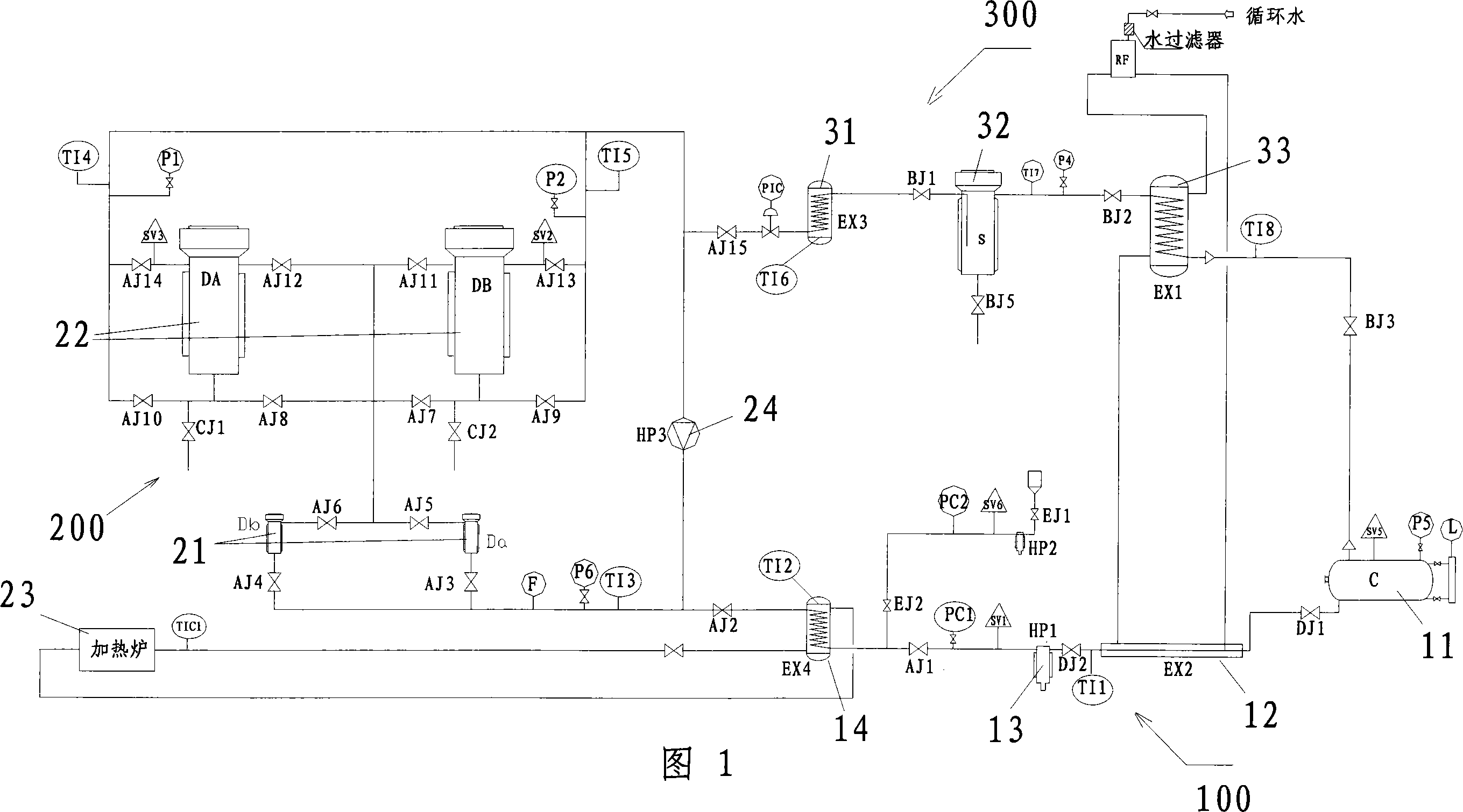

[0022] The present invention provides a continuous dyeing production system using supercritical fluid, which includes a supercritical fluid supply device 100 , at least two sets of dyeing circulation devices 200 and a supercritical fluid recovery device 300 connected to each other.

[0023] The supercritical fluid supply device 100 is used to supply the supercritical fluid to the dyeing cycle device 200 , and includes a storage tank 11 , a subcooler 12 , a main high pressure pump 13 and a preheater 14 connected by pipelines in sequence. The storage tank 11 is used to store and contain liquid working fluid, and the volume can be set according to the production requirements, for example: for a storage tank of 300L-10000L, the pressure limit of the tank body can be designed as 8MPa, the maximum working temperature is 30°C, and the top of the tank body It is equipped with gas inlet, safety valve interface, pressure gauge interface and emptying port. At the same time, the bottom is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com