An oxygen sensor and a method utilising it

An oxygen sensor and gas technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problem of destroying the organic residual products of the oxygen sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The two embodiments have a number of features in common, so below the same reference numerals will be used to identify corresponding parts of the two embodiments.

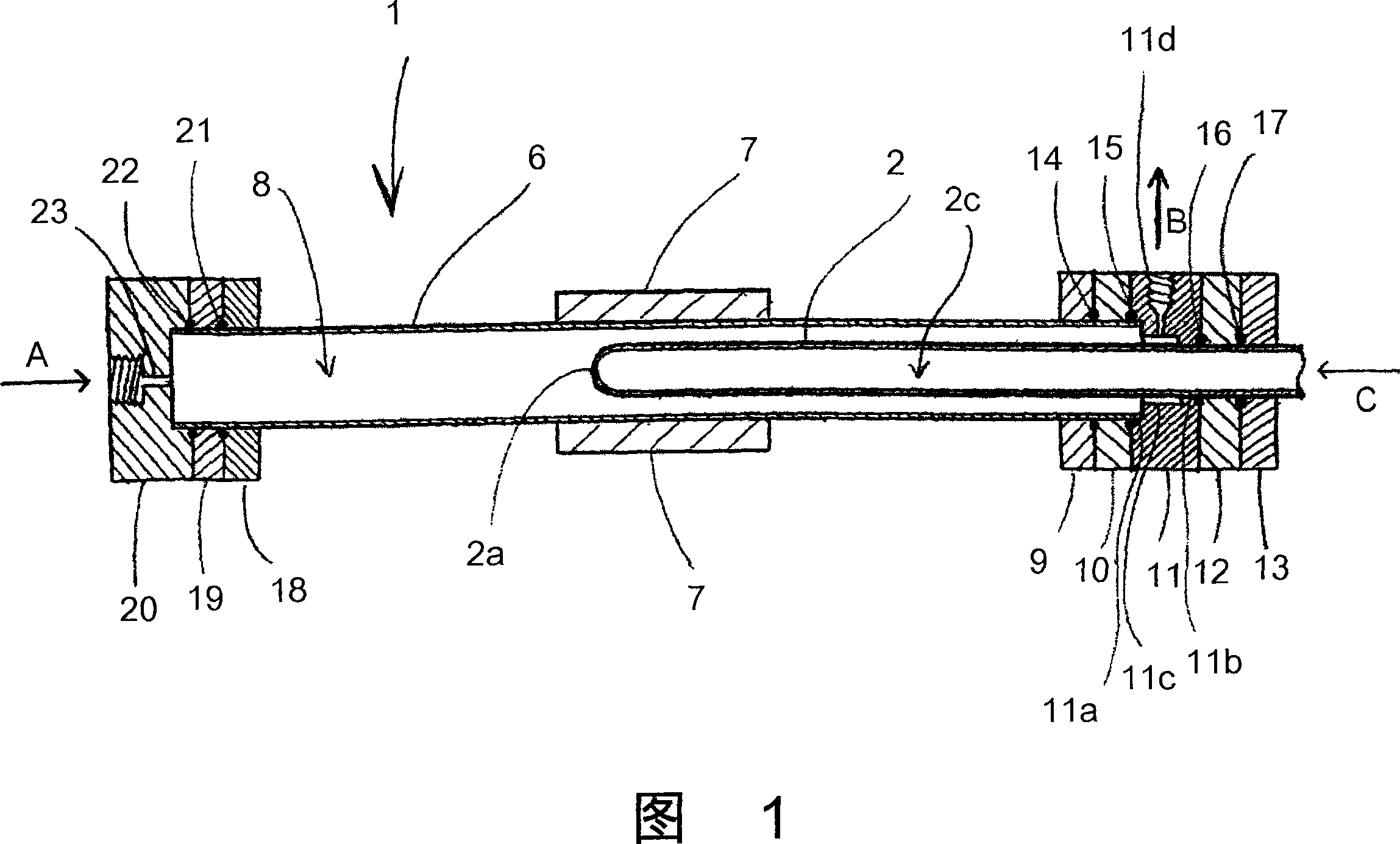

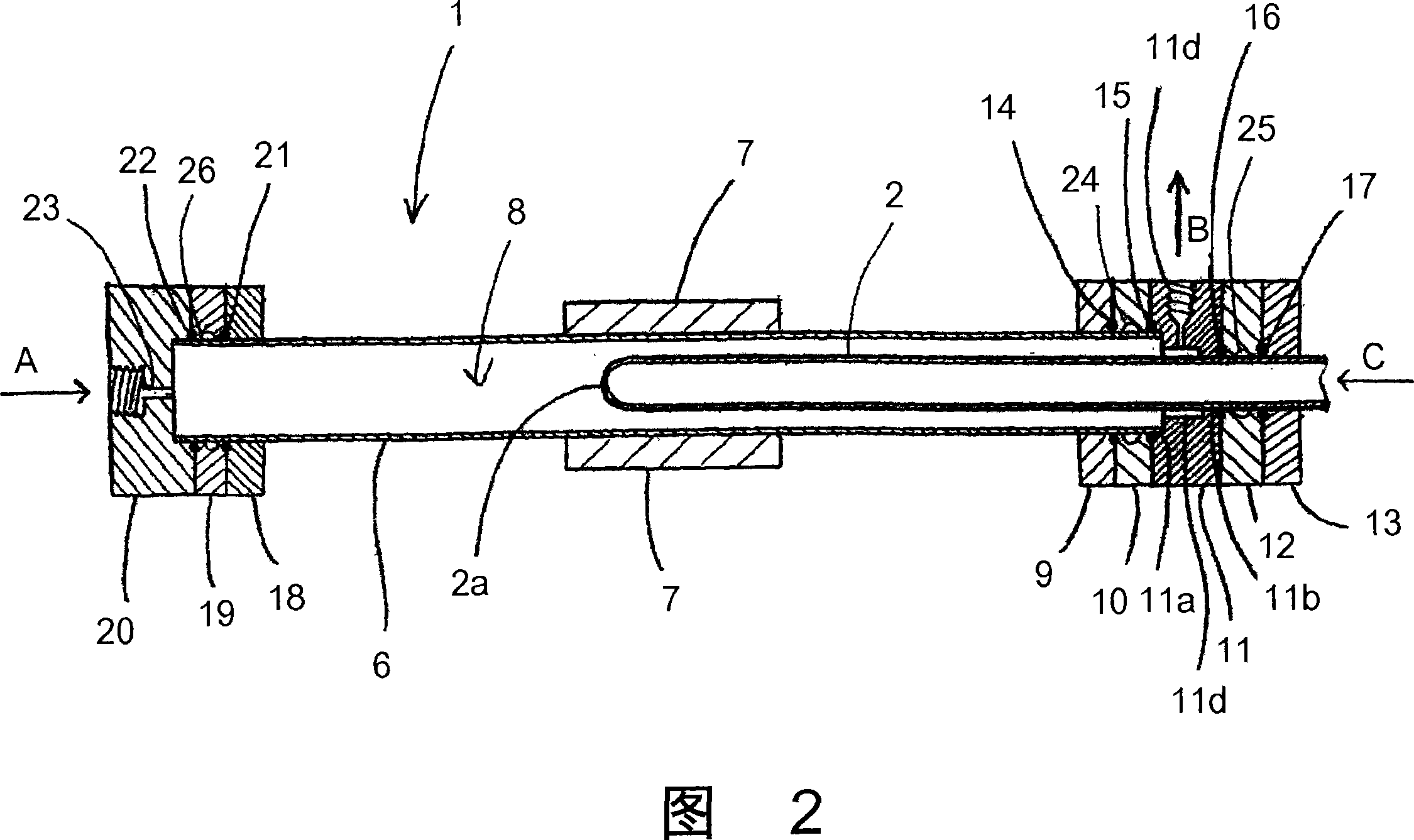

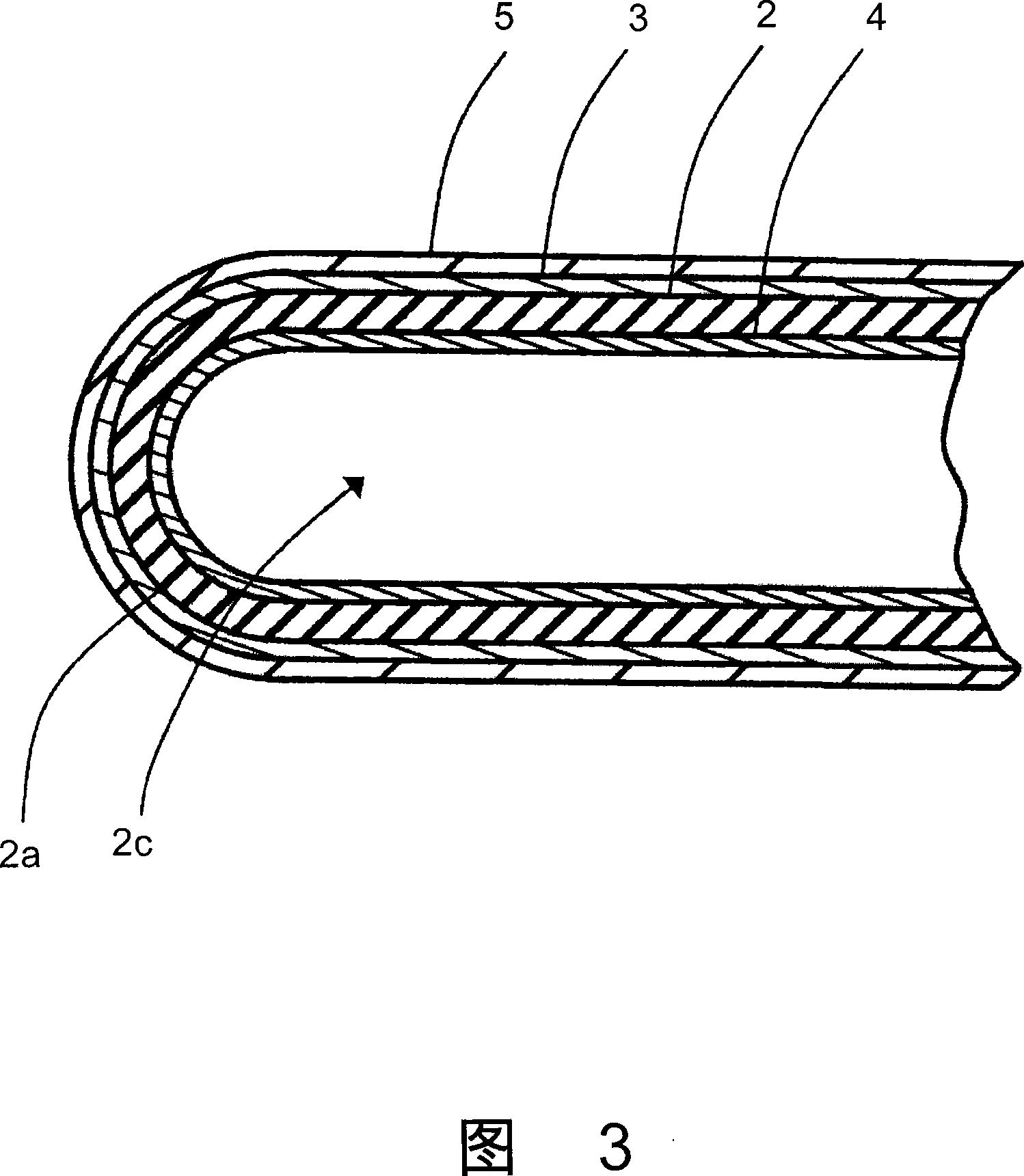

[0039] FIG. 1 schematically shows a section through an oxygen sensor 1 according to the invention. The oxygen sensor comprises a membrane in the form of a first tube 2 . The first tube 2 is basically made of stabilized zirconia (ZrO 2 )production. The first tube 2 is preferably cylindrical, but ends in a hermetically closed end 2a, which is integral with the rest of the tube, while the other end (not shown) is open. The first tube 2 is positioned such that it extends at least partly into the second tube 6, which is also preferably cylindrical. Preferably, the first tube 2 is placed concentrically with the second tube 6, as shown in Figures 1 and 2, that is, the open end of the first tube is located outside the second tube 6, and the closed end 2a is positioned approximately into the second tube half the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com