Circuit base board, its encapsulation structure, and making method of the encapsulation structure

A circuit substrate and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of increasing the cost of the process, increasing the complexity of the process, and achieve the effect of reducing the cost of the process and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

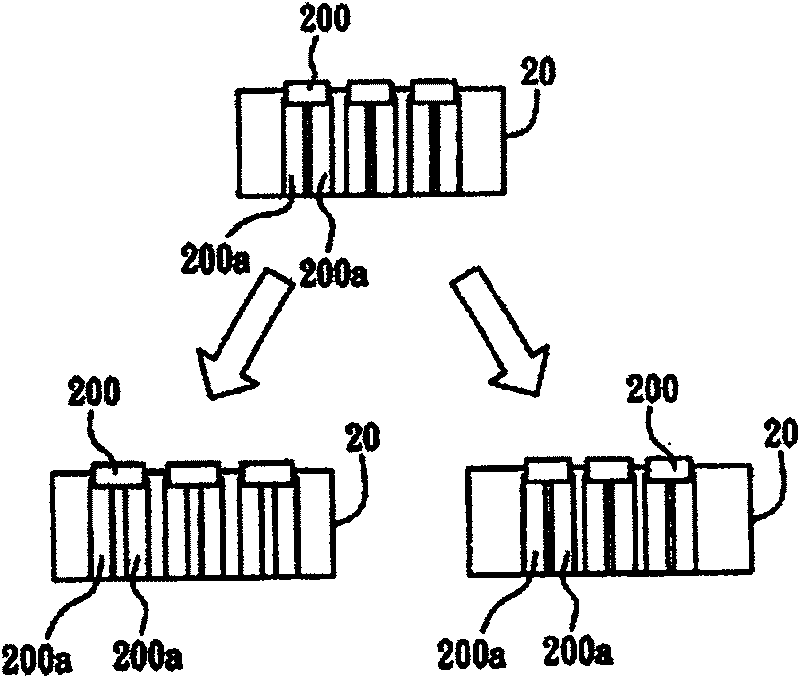

[0030] see Figure 2A It is a schematic plan view of the circuit substrate of the present invention. A plurality of electrodes 200 are formed on the surface of the circuit substrate 20, and each electrode 200 is formed with at least two forked structures 200a. As shown in the figure, the circuit substrate 20 expands the electrode 200 used for signal conduction with the outside world and splits it into two forks, that is, a distance is formed between the at least two forked structures 200a to increase the The combination probability that the electrode can be aligned with the external circuit board electrode.

[0031]The circuit substrate 20 is a plastic substrate, such as a flexible substrate (flexible substrate) used in a flexible display, and the insulating plastic substrate used in the circuit substrate 20 is, for example, polyethersulfone (Polyethersulfone, PES), and its glass The conversion temperature is about 200-220°C, and the thermal expansion coefficient is about 50-...

Embodiment 2

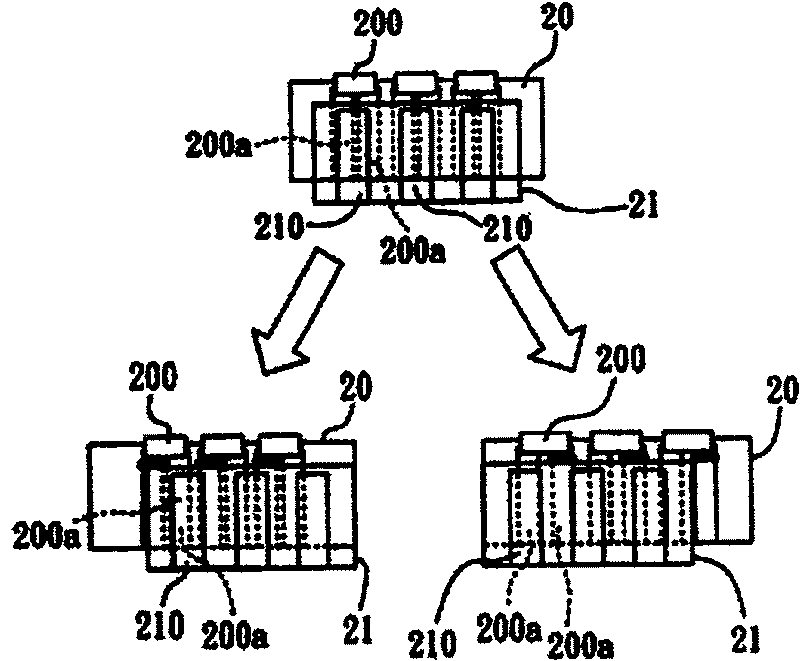

[0043] Figure 4A and Figure 4B It is a schematic plan view of Embodiment 2 of the circuit substrate of the present invention, and a schematic plan view of Embodiment 2 of the structure of the circuit substrate.

[0044] As shown in the figure, the circuit substrate and its assembly structure of Embodiment 2 of the present invention are substantially the same as the above-mentioned Embodiment 1, the main difference is that the forked structure formed on the circuit substrate 30 on the electrode 300 is in the shape of a grid 300a, so , not only can further increase the probability of alignment combination between the electrode 300 of the circuit substrate 30 and the electrode 310 of the external circuit board 31, but also increase the number of conductive particles captured in the anisotropic conductive film under the electrode of the circuit substrate 30 and the circuit board 31, and reduce the Combine resistors and increase the chance of conduction.

[0045] Furthermore, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com