Intelligentized manipulator paw mechanism for piling machine

A technology of manipulators and palletizers, applied in the field of claw mechanisms, can solve problems such as large stack gaps, loose stack shapes, and poor uniformity, and achieve the effect of eliminating gaps and reducing drop heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

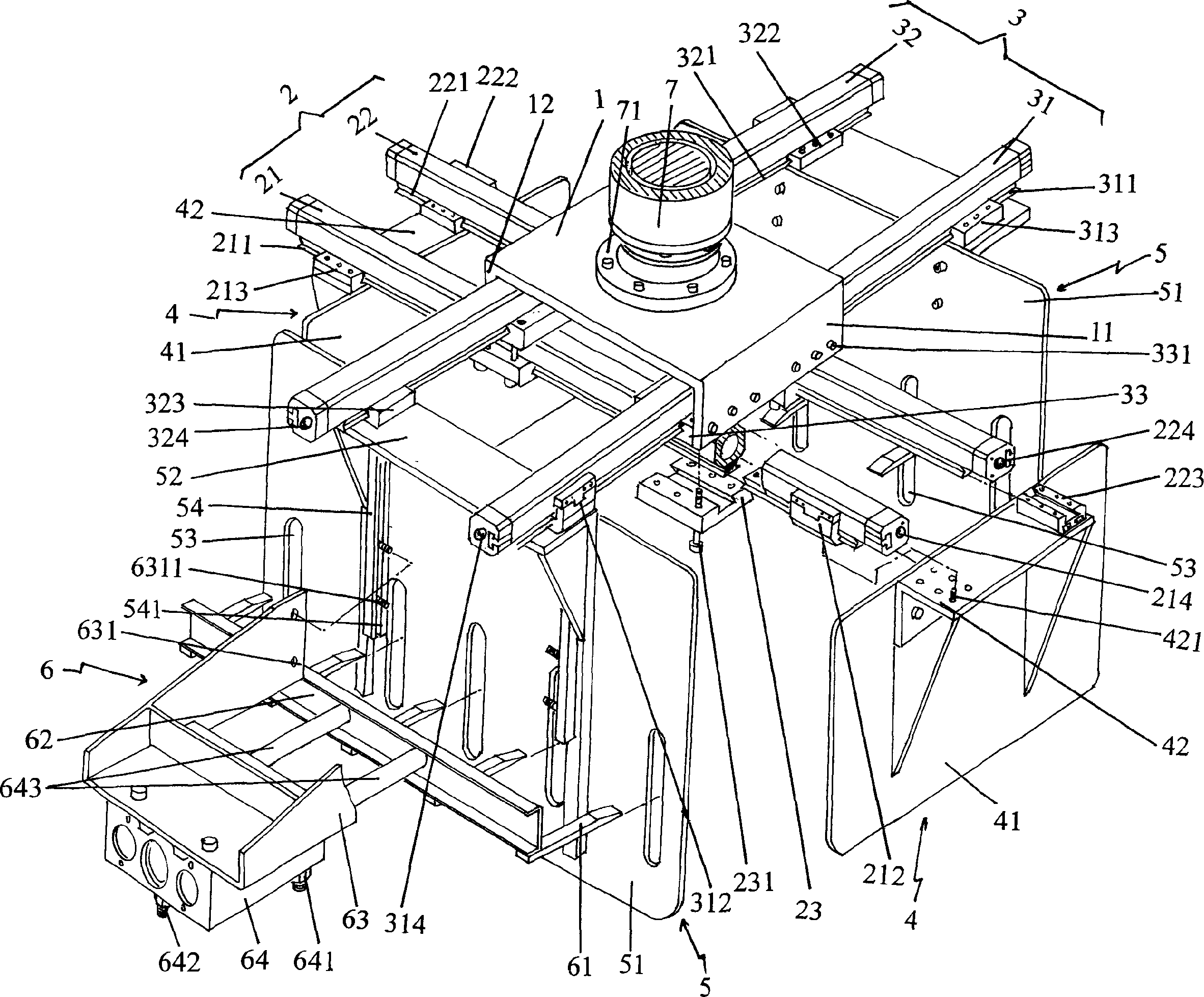

[0017] The applicant described in detail the technical features and the expected technical effects of the present invention with reference to the accompanying drawings. However, the description of all embodiments does not constitute a specific limitation on the technical solutions of the present invention, that is to say, any Equivalent changes or formal modifications based on the technical content disclosed by the applicant, especially the defined protection scope, should be regarded as the scope covered by the patent.

[0018] Please in conjunction with the accompanying drawings, the arm 7 as an intelligent manipulator is fixed on the grasping palm 1 of the present invention by the connecting legal edge 71 at the end, that is to say that the center of the top surface of the grasping palm 1 given by the applicant is Fixedly connected with arm 7. A pair of first driving device 2 is made of a pair of first and second action cylinders 21,22 that are preferably rodless cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com