Overpressure resistant and explosion-proof mobile gas-liquid heating equipment

A heating equipment, mobile technology, applied in the direction of lighting and heating equipment, mechanical equipment, water heaters, etc., can solve the problems of affecting production operations, reducing visibility, and easily causing fires, etc., to achieve long residence time, long service life, Good mechanical properties and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

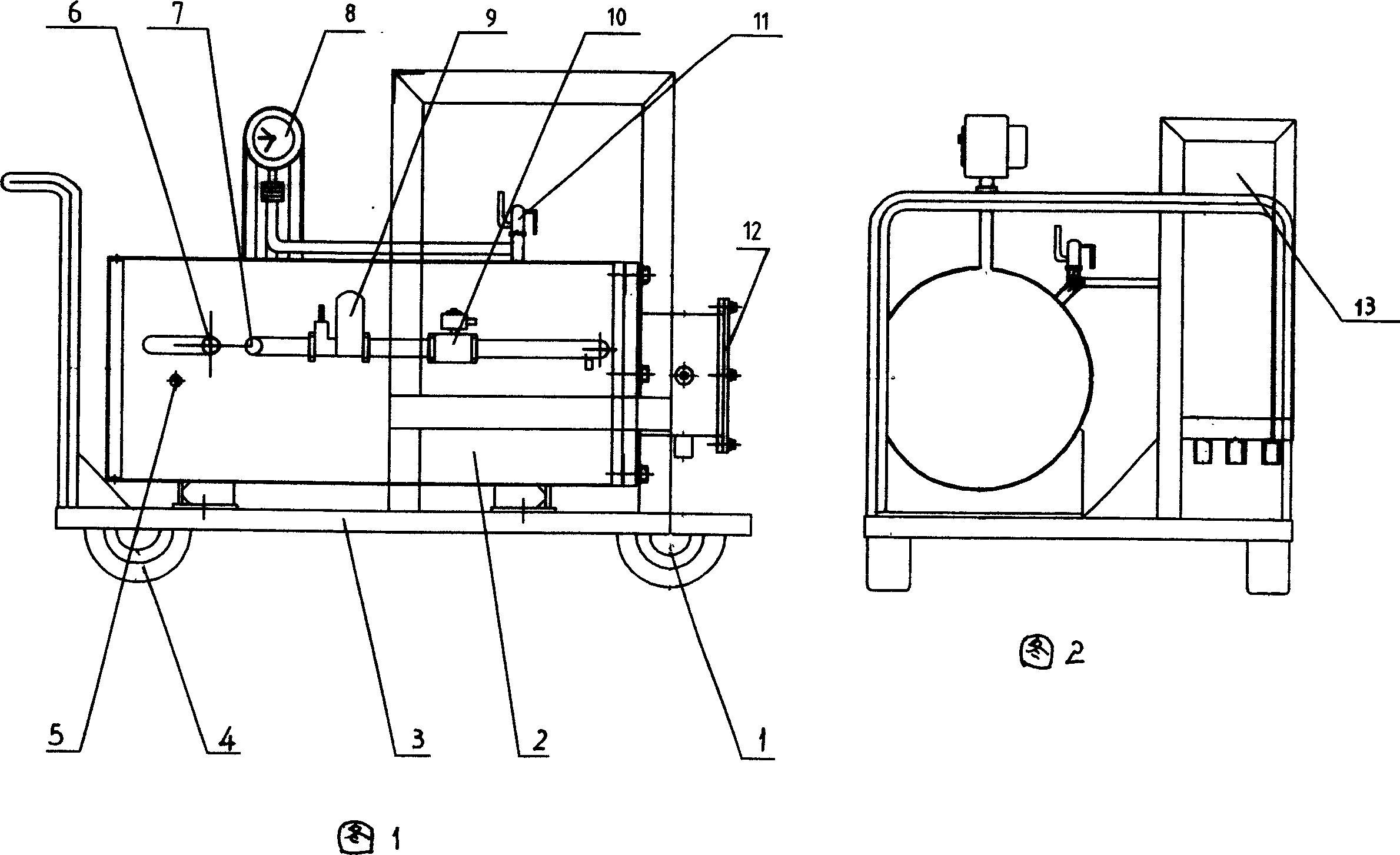

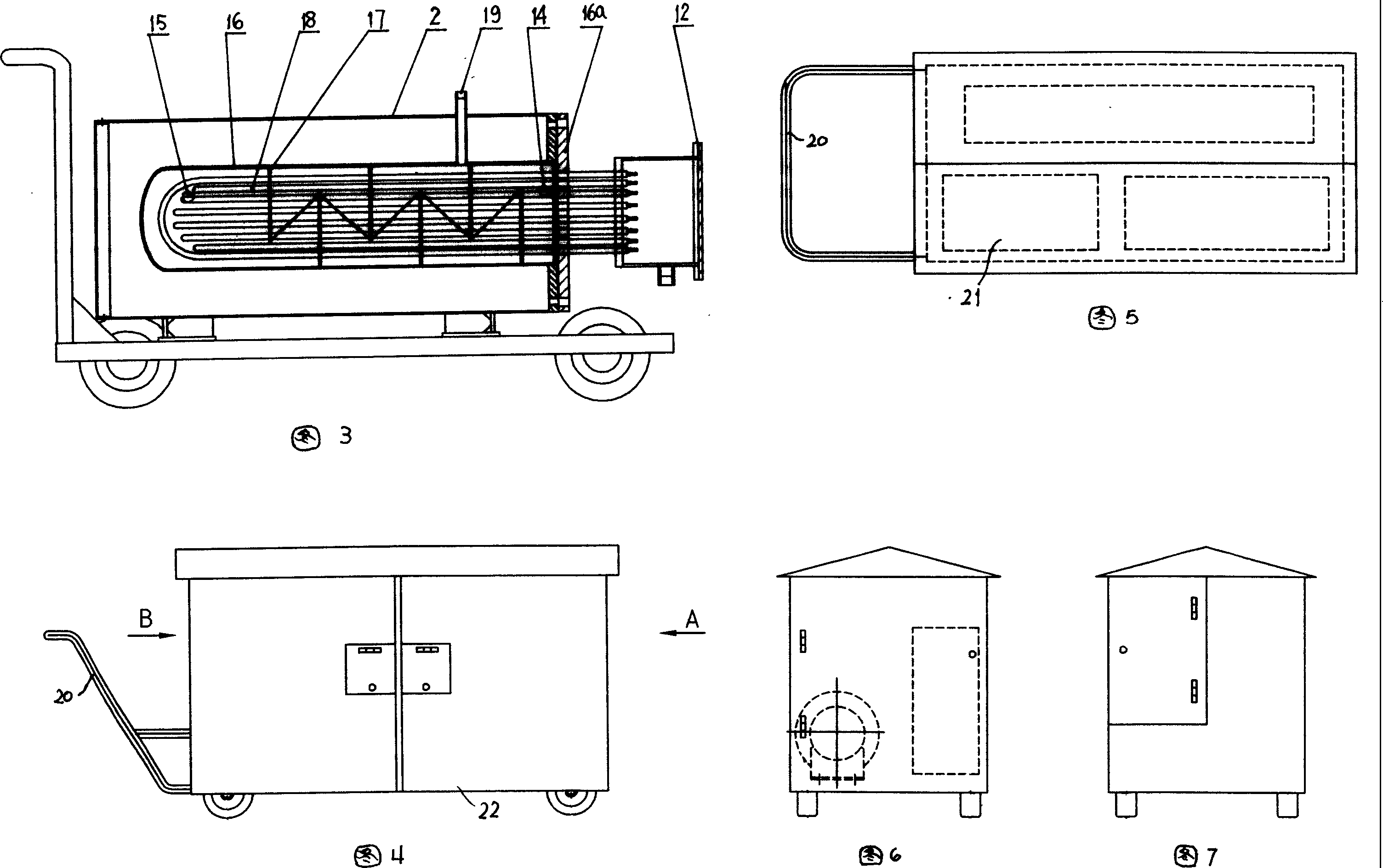

[0027] Figure 3 shows that an explosion-proof electric heating device is installed on the trolley 3: the electric heating assembly is assembled in a pressure vessel 16 by a plurality of electric heating tubes, and is bundled and fixed on the flange end 16a of the pressure vessel; a plurality of baffles 17 along the The axes of the pressure vessel 16 are fixed on the inner wall of the pressure vessel one by one with dislocations up and down, the inlet of the heating medium is set near the flange end of the vessel, the outlet is set near the head end of the vessel, and the vessel is provided with a pressure relief safety valve 11 , automatic electric control device is explosion-proof automatic electric control cabinet 13 (Fig. 2) and temperature automatic control device are all installed on the dolly. The shape of the baffle plate 17 is 2 / 3 of the circular cross section of the pressure vessel 16 . Referring to Fig. 3, after the air enters from the heating medium inlet 14 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com