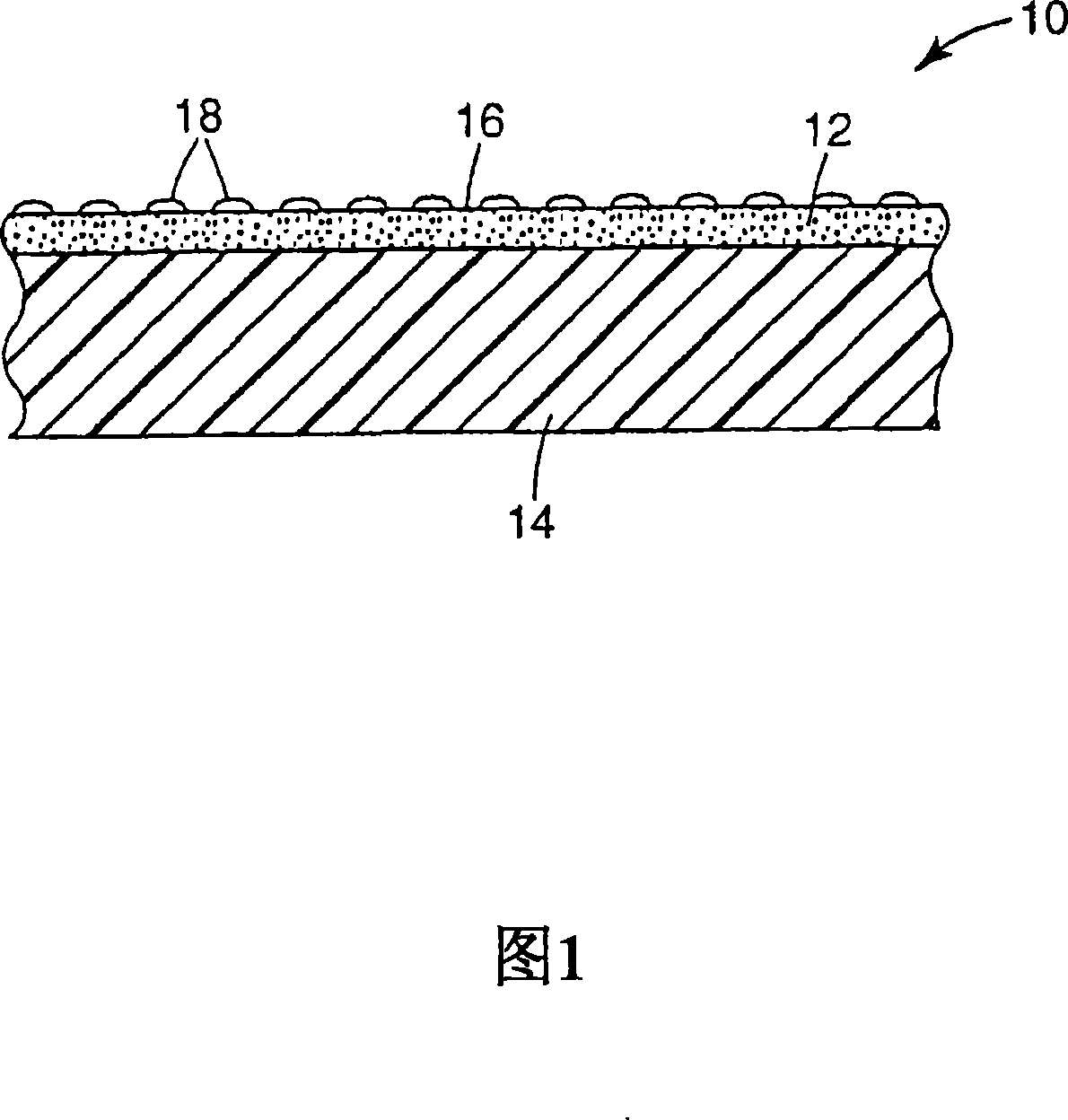

Biologically-active adhesive articles and methods of manufacture

A technology of biologically active substances and products, applied in medical science, coatings, absorbent pads, etc., can solve the problems of reducing the effect of wound care products, affecting the physical properties of the PSA layer, reducing the adhesive strength of the PSA layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

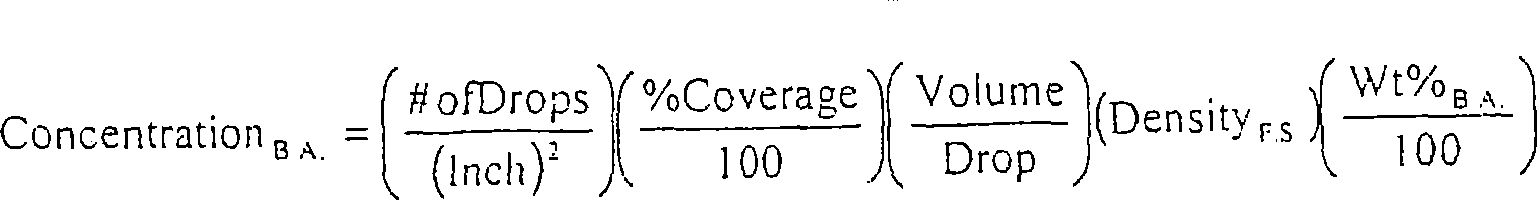

[0113] A mixture of 1.0% silver (I) oxide and 5.0% ammonium carbonate was heated to 60° C. and stirred until the silver (I) oxide was dissolved to prepare its aqueous solution. The fluid solution was ink-jet printed on the adhesive surface of Tegaderm using "XAARXJ128-200 print head" with 100% surface coverage. The print head is driven by 1.25kHz and 3.5V piezoelectric, with a printing resolution of 300×300dpi. The normal volume of the fluid solution drop thus produced is about 70 pL. The sample was then dried in an oven at 150°C for 10 minutes.

Embodiment 2

[0115] The fluid solution in Example 1 was ink-jet printed on the adhesive surface of Tegaderm with a surface coverage of 200% according to the ink-jet printing method described in Example 1 and dried.

Embodiment 3

[0117] The fluid solution in Example 1 was ink-jet printed on the adhesive surface of Tegaderm with 100% surface coverage according to the ink-jet printing method described in Example 1, but the coated sample was dried at room temperature (25°C) 24 hour.

[0118] Buying example 4

[0119] The fluid solution in Example 1 was ink-jet printed on the adhesive surface of Tegaderm HP with 100% surface coverage according to the ink-jet printing method described in Example 1 and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com