Apparatus for transferring of glass panel

A flat glass, conveying device technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

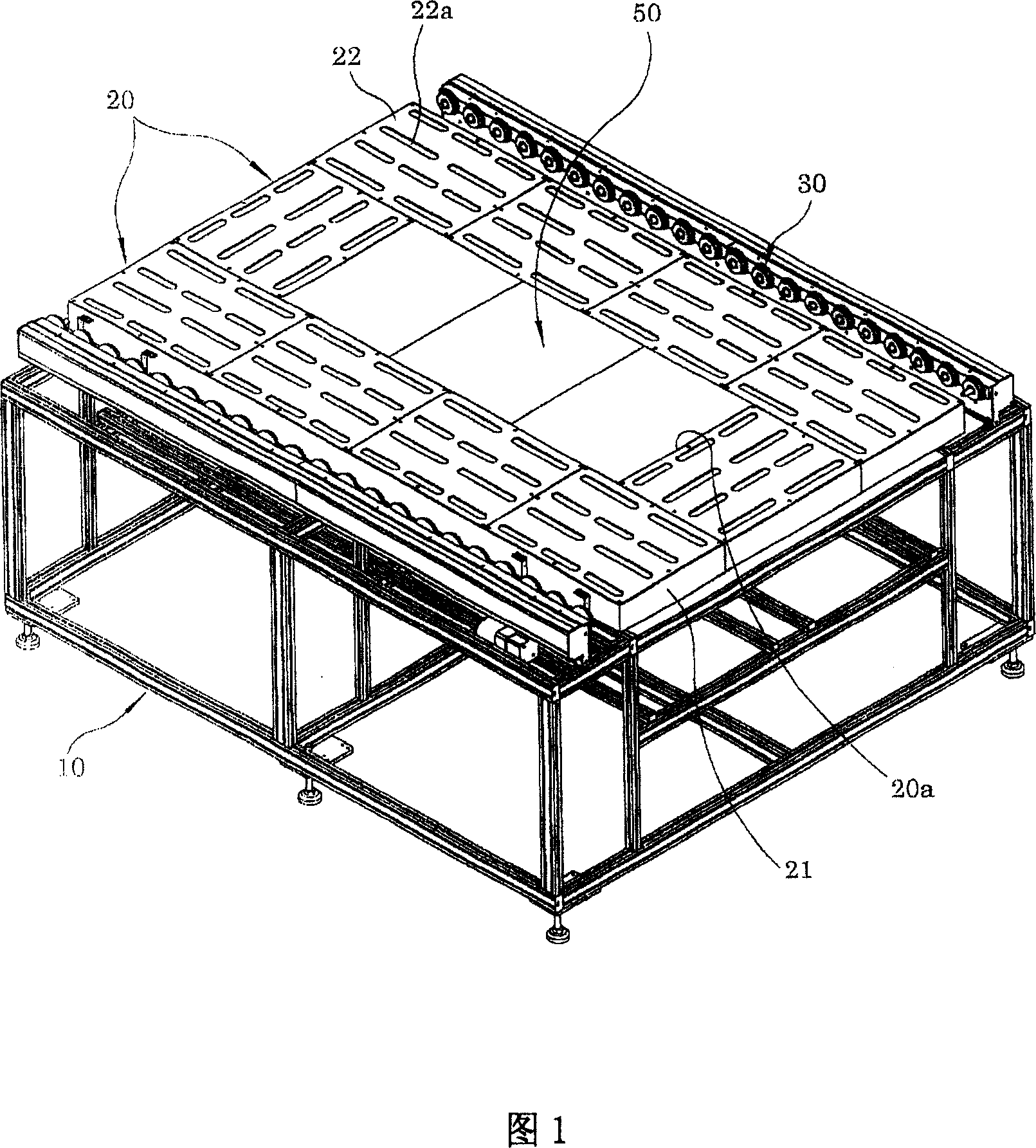

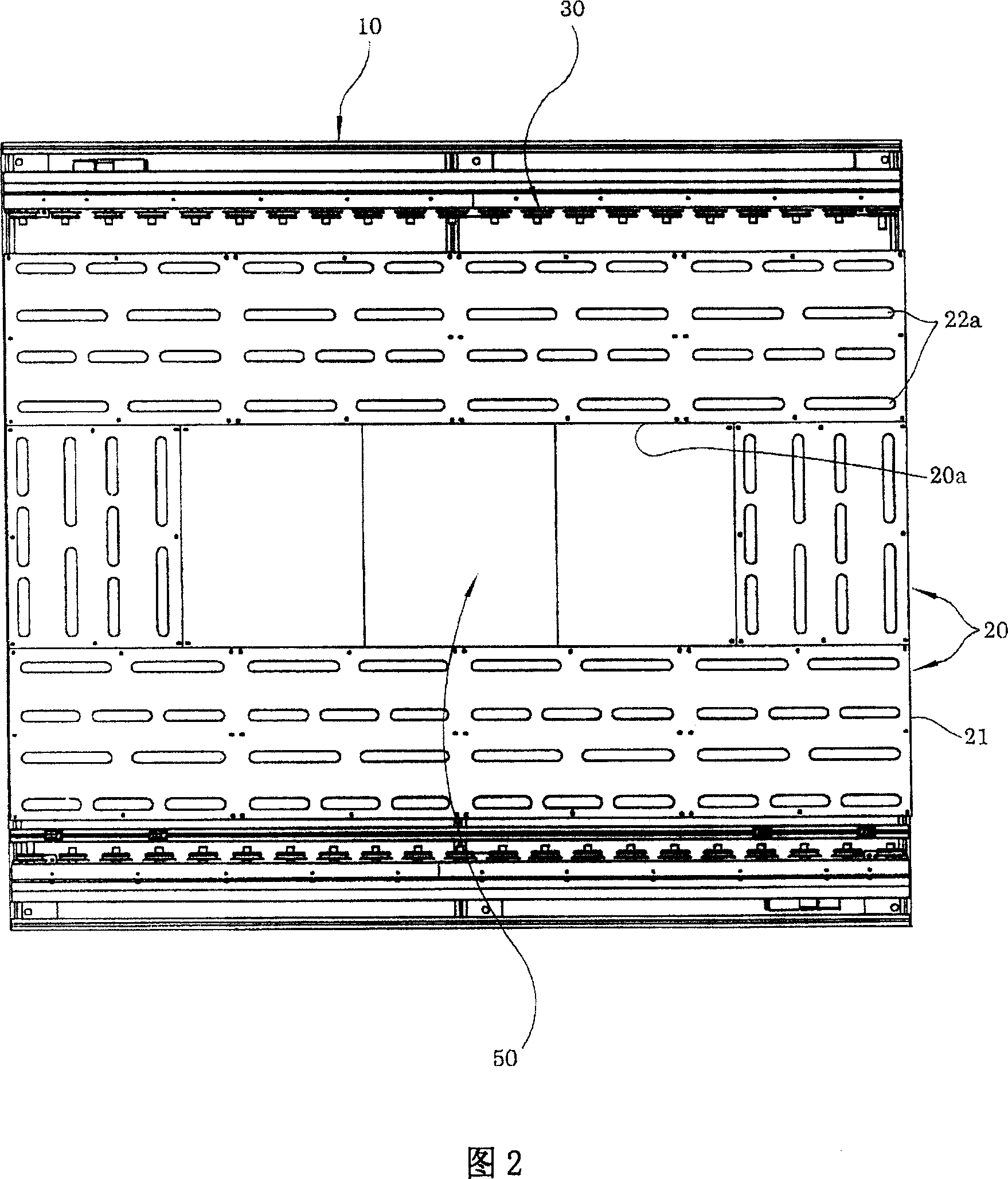

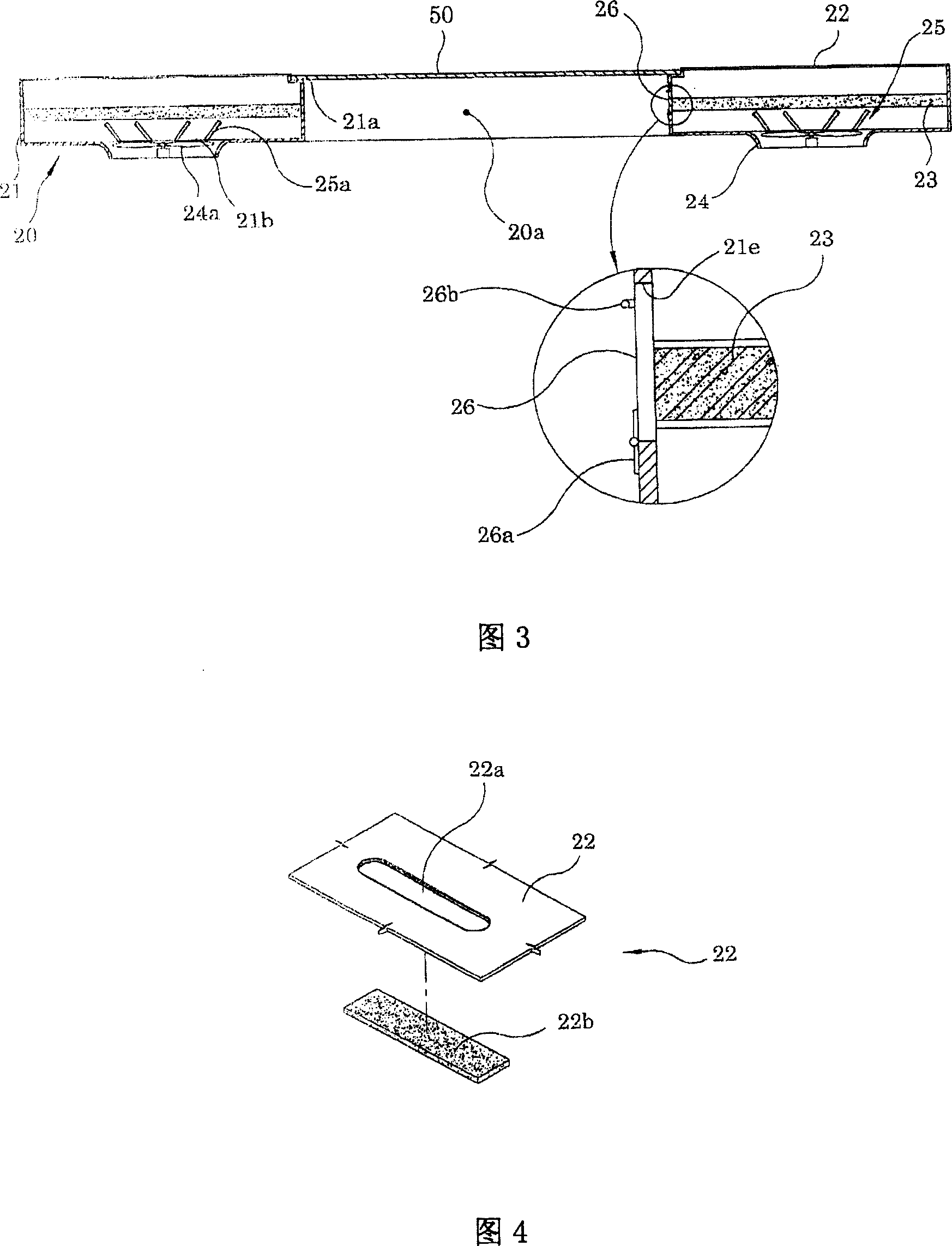

[0036] Fig. 1 is a perspective view of a flat glass conveying device according to a first embodiment of the present invention, Fig. 2 is a top view of a flat glass conveying device according to a first embodiment of the present invention, and Fig. 3 shows a flat glass according to a first embodiment of the present invention Fig. 4 is an enlarged exploded perspective view showing partial highlights of the top plate of the air flotation device in the flat glass conveying device according to the first embodiment of the present invention.

[0037] The plate glass conveying device according to the first embodiment of the present invention includes: an air flotation device 20, which is arranged on the upper part of the workbench 10, and discharges the air supporting the plate glass 40; a conveyor 30, which is arranged on the above air flotation device 20 The two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com