Method of pressing bearing on crankshaft

A crankshaft and bearing technology is applied to the field of press-fitting bearings on the crankshaft, which can solve the problems of easy deformation at the crankshaft of the crankshaft and affect the quality of the crankshaft, and achieve the effect of preventing deformation under force and ensuring the quality of press-fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

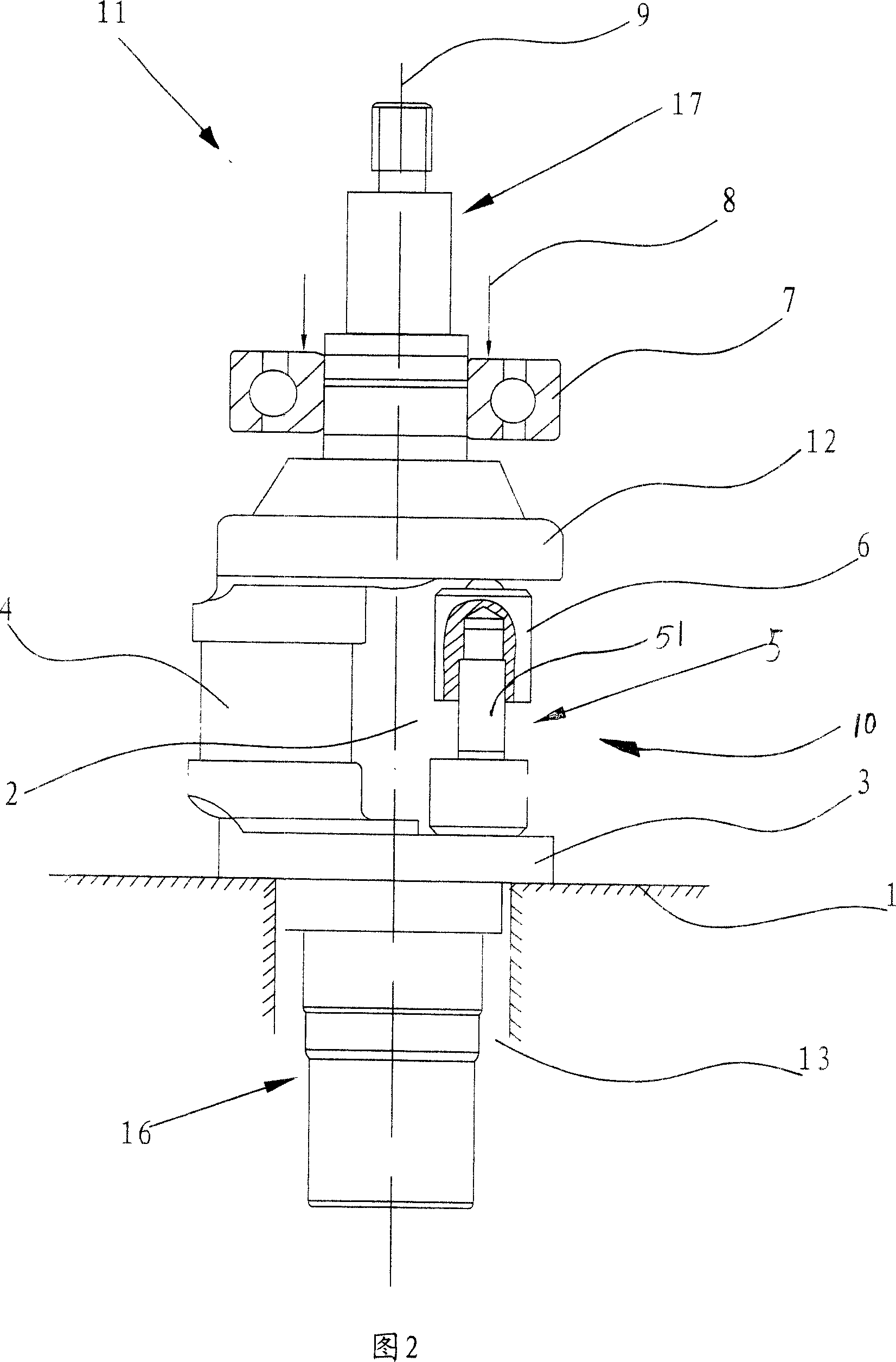

[0022] Accompanying drawing 2 represents the method for installing bearing on crankshaft among the embodiment one, comprises the following steps:

[0023] (a), the crankshaft 11 is fixed on the support frame 1, the support frame 1 is provided with a mounting hole 13, the second main shaft 16 of the crankshaft 11 penetrates into the described mounting hole 13 and makes the The second main journal 3 of the crankshaft 11 is fixedly mounted on the upper mouth of the mounting hole 13;

[0024] (b), the bearing 7 to be installed is sleeved on the upper side of the mounting portion of the crankshaft 11 and the axis line of the bearing 7 coincides with the axis line 9 of the crankshaft 11; The vacant part 2 of the crankshaft 11 is placed along the axis 9 direction of the crankshaft 11. The jack 10 includes a bolt 5 and a screw threaded on the screw 51 of the bolt 5. The cap 6, the bolt 5 is pressed against the upper end surface of the second main journal 3, the nut 6 is pressed again...

Embodiment 2

[0027] Accompanying drawing 3 represents the method for installing bearing on crankshaft among the embodiment two, comprises the following steps:

[0028] (a), the crankshaft 11 is fixed on the support frame 1, the support frame 1 is provided with a mounting hole 13, the second main shaft 16 of the crankshaft 11 penetrates into the described mounting hole 13 and makes the The second main journal 3 of the crankshaft 11 is fixedly mounted on the upper mouth of the mounting hole 13;

[0029] (b), the bearing 7 to be installed is sleeved on the upper side of the mounting portion of the crankshaft 11 and the axis line of the bearing 7 coincides with the axis line 9 of the crankshaft 11; The vacant part 2 of the crankshaft 11 is placed along the axis 9 direction of the crankshaft 11. The jack 10 includes a lead screw 19 and a nut threaded on the lower end of the lead screw 19. 18. The top cap 20 is fixedly sleeved on the upper end of the screw 19, the top cap 20 is pressed against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com