Hydraulic up-down swing mechanism

A slewing mechanism, hydraulic technology, applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems of large installation space, high failure rate, complex structure, etc., to ensure control accuracy , Guarantee the effect of angular position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

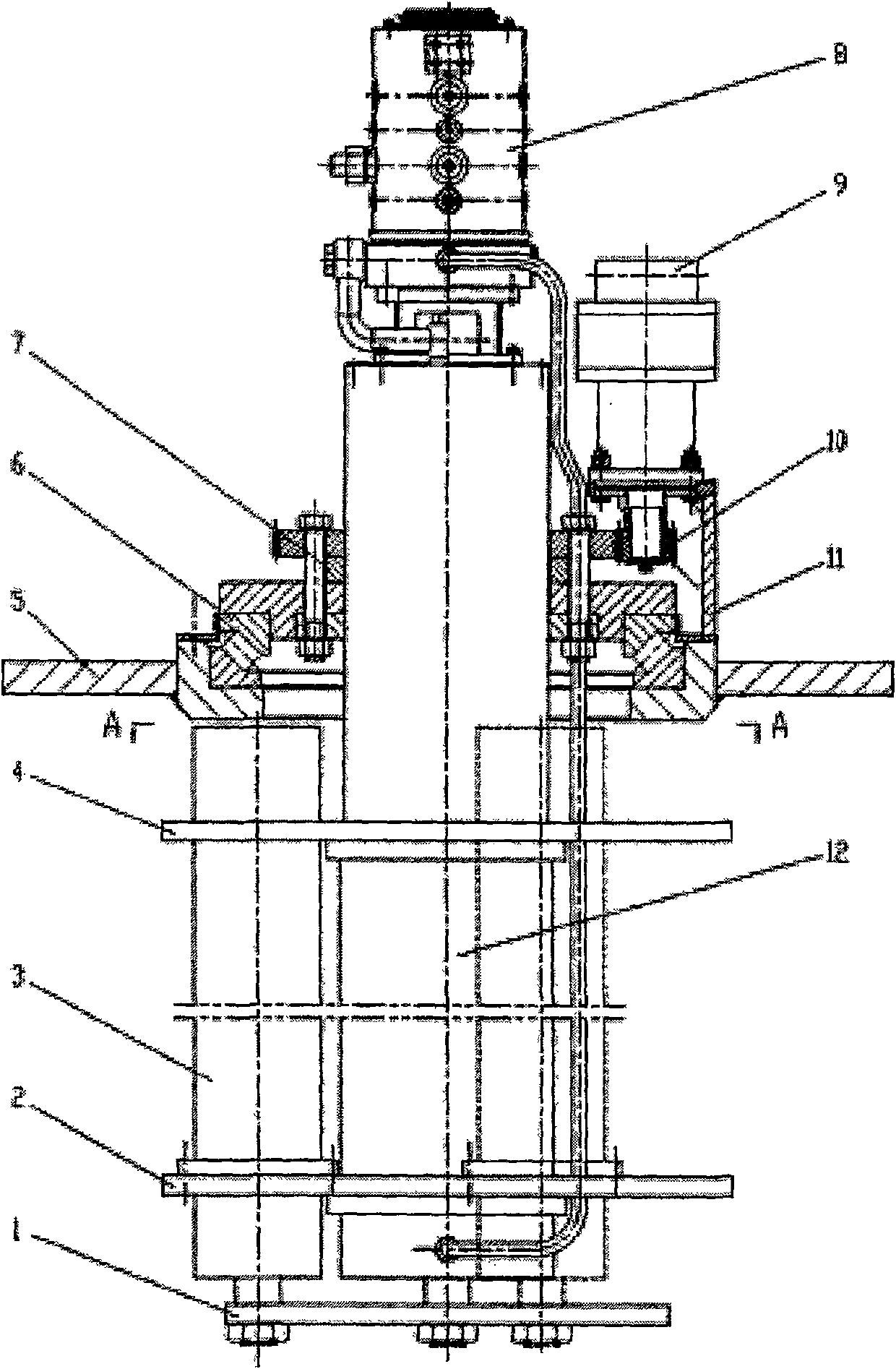

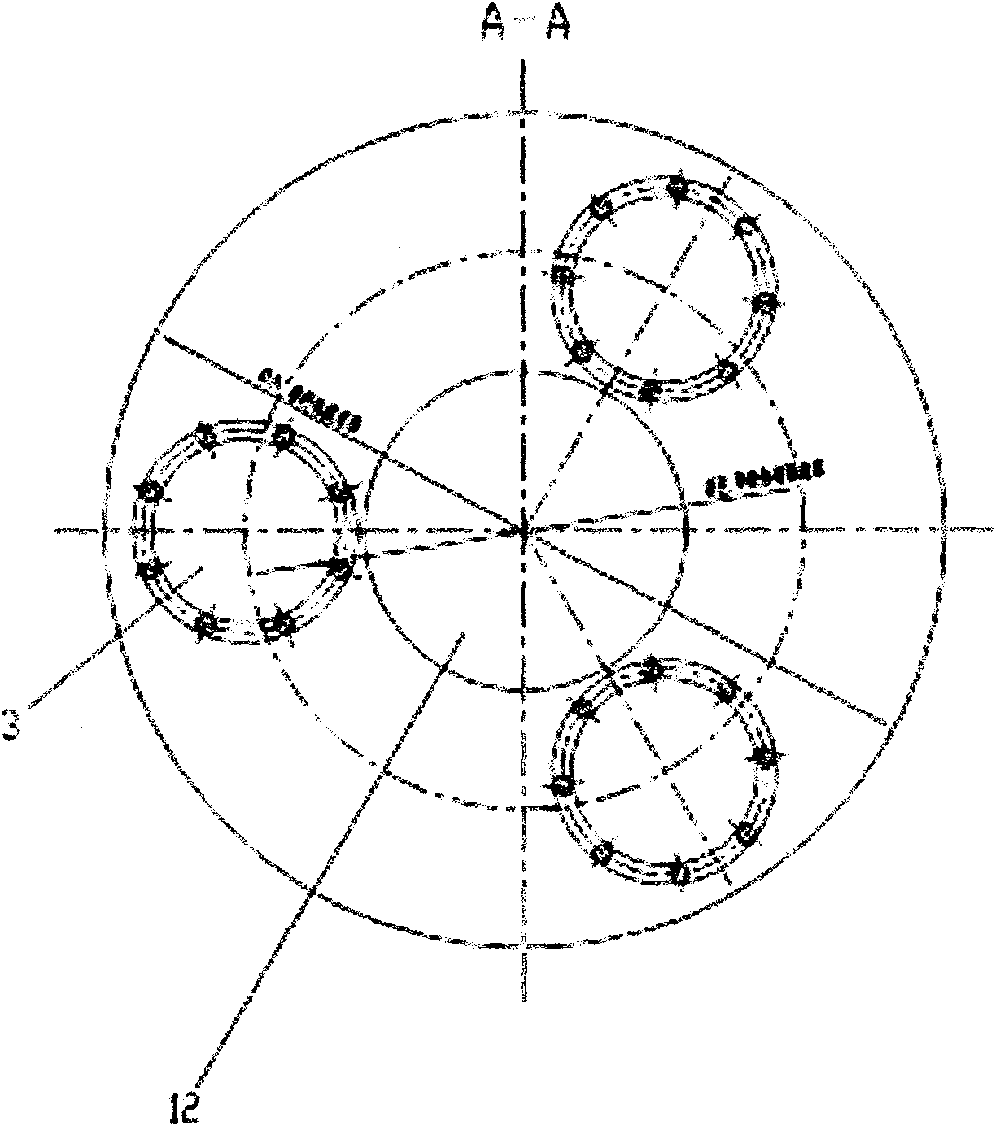

[0017] Such as figure 1 , figure 2 As shown, three groups of telescopic connecting rods 3 are distributed around the hydraulic cylinder 12 at a distance of 120° around the multi-stage single-rod double-acting multi-stage telescopic hydraulic cylinder 12. The connecting rods are fixed together on the load platform 1; the load platform 1 is mainly a connection platform for load parts. The upper support guide plate 4 and the lower support guide plate 2 are sleeved up and down on the hydraulic cylinder 12 and the telescopic connecting rod 3, and the upper support guide plate 4 and the lower support guide plate 2 play a supporting and guiding role. The lifting of the hydraulic cylinder 12 will drive the telescopic connecting rod 3 and the load platform 1 to lift together.

[0018] The upper part of the three sets of telescopic connecting rods 3 has a round table or a round table with ears main support platform 5, a round table or a round table with ears main support platform 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com