Fuel oil and electric dual-purpose special type engineering machinery

A dual-purpose electric and construction machinery technology, which is applied in mechanical equipment, machines/engines, fluid pressure actuation devices, etc., can solve the problems of no public satisfaction, etc., and achieve the effects of reducing operating costs, eliminating pollution, and long maintenance cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

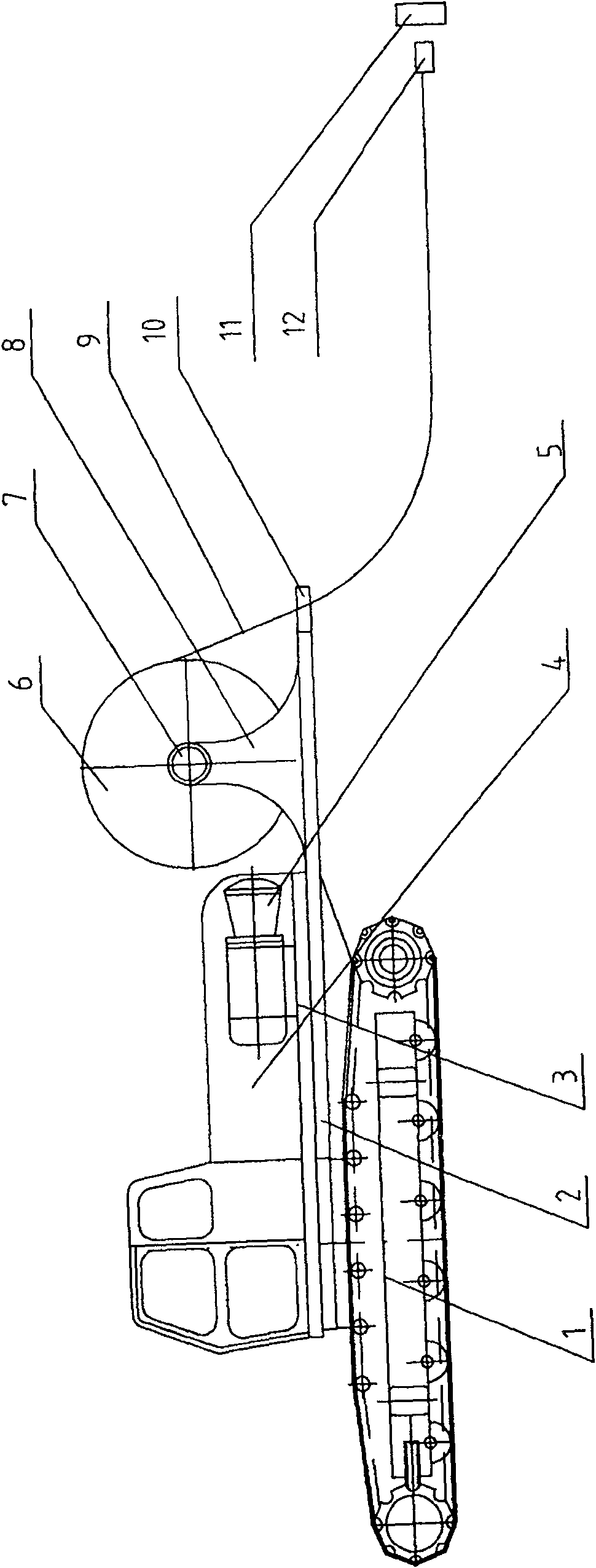

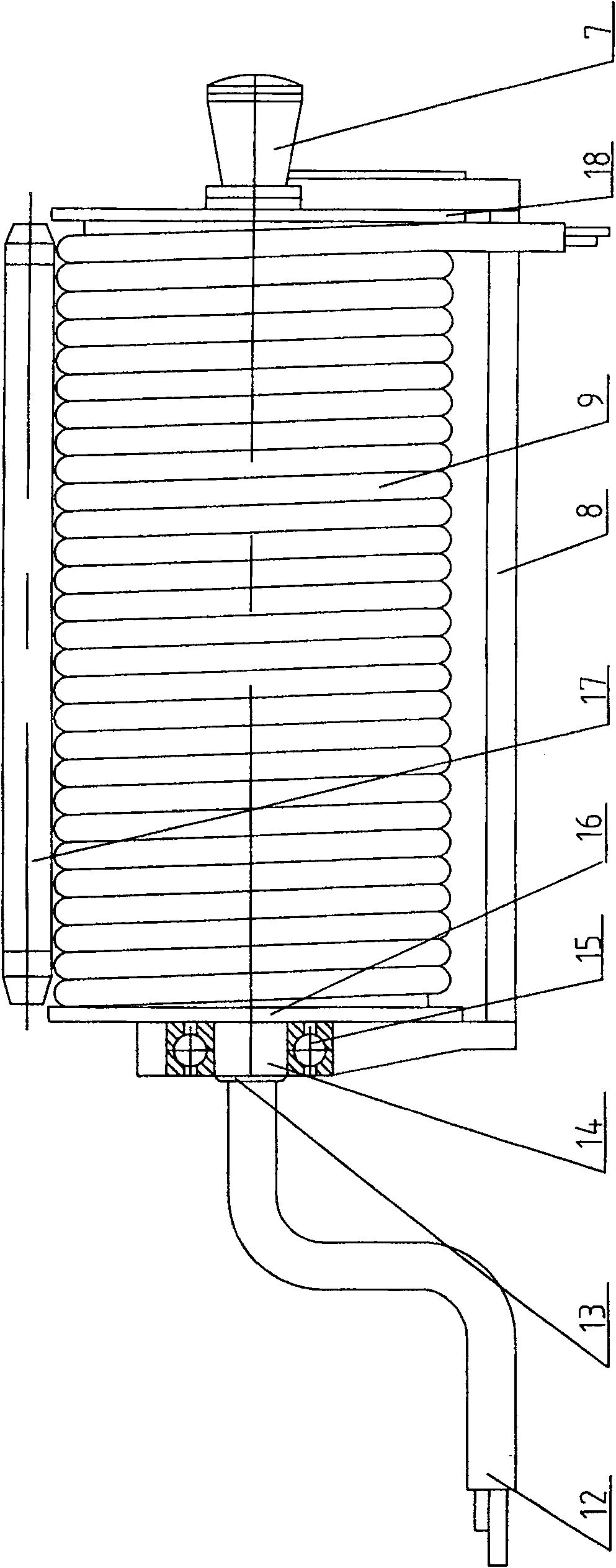

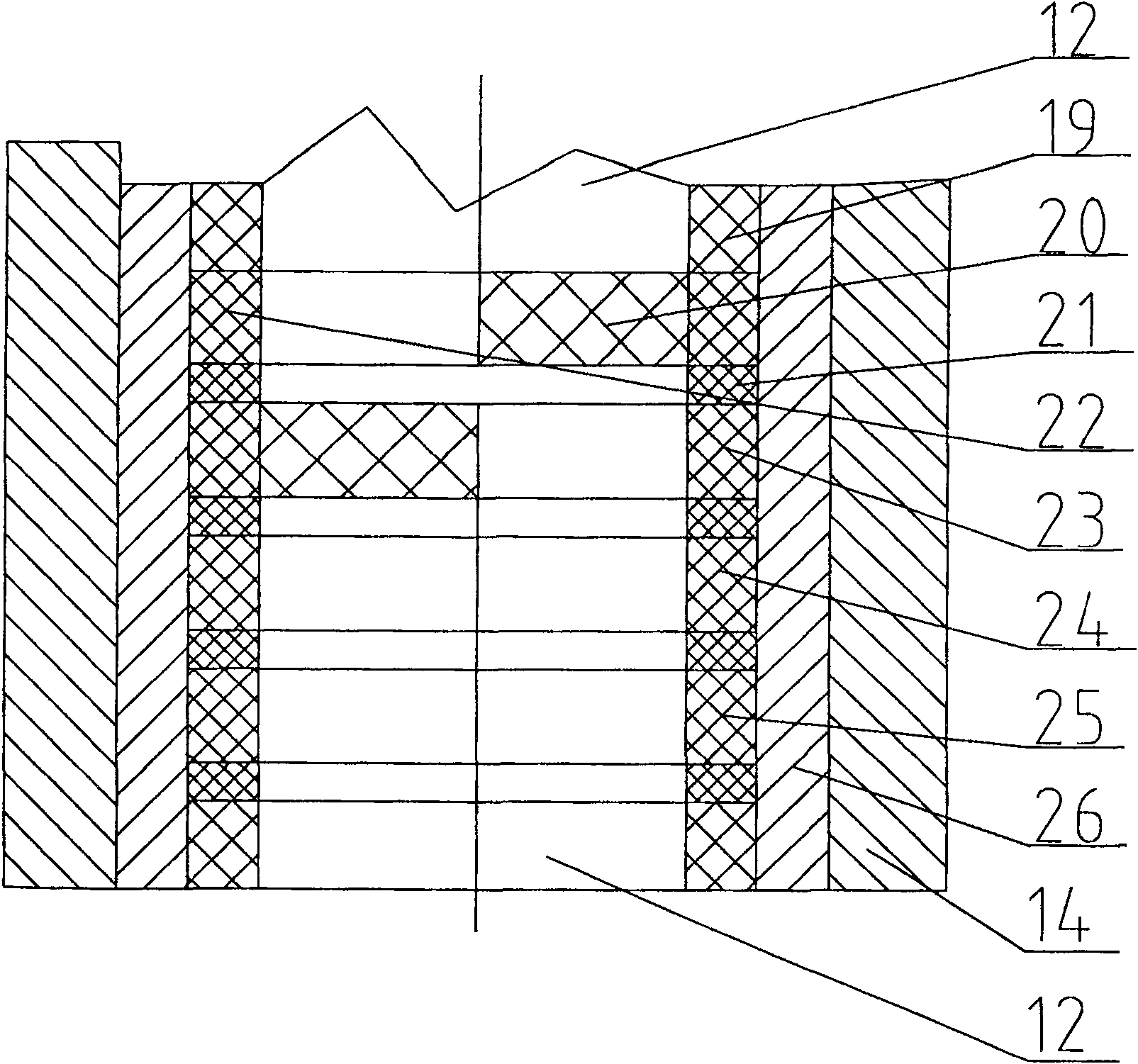

[0030] See figure 1 . The invention relates to a fuel-electric dual-purpose special engineering machine. It has a self-propelled frame 1 on which a central turntable is provided. The turning disk 3 of the central turntable is provided with a power system, a hydraulic pump station, and a hydraulic System, control circuit, operating system (not shown), the fixed disk 2 of the central turntable is connected to the walking system, the tail of the fixed disk 2 is fixed with a reel bracket 8, and the reel bracket 8 is equipped with a cable reel 6 and a reel oil motor 7. The power system drives the hydraulic pump station and walking system, the hydraulic pump station provides pressure oil to the hydraulic system, and the hydraulic system drives the operating system. among them:

[0031] The power system includes a fuel engine 4 and an AC motor 5; the hydraulic pump station includes a hydraulic pump station driven by a fuel engine and an electric hydraulic pump station driven by an AC m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com