Vehicle horn driving circuit

A driving circuit and speaker technology, which is applied to vehicle components, sounding devices, instruments, etc., can solve problems such as poor sounding, and achieve the effects of suppressing voltage changes, avoiding large-scale, and reliable sounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, an embodiment of the present invention will be described based on an embodiment of the present invention shown in the drawings.

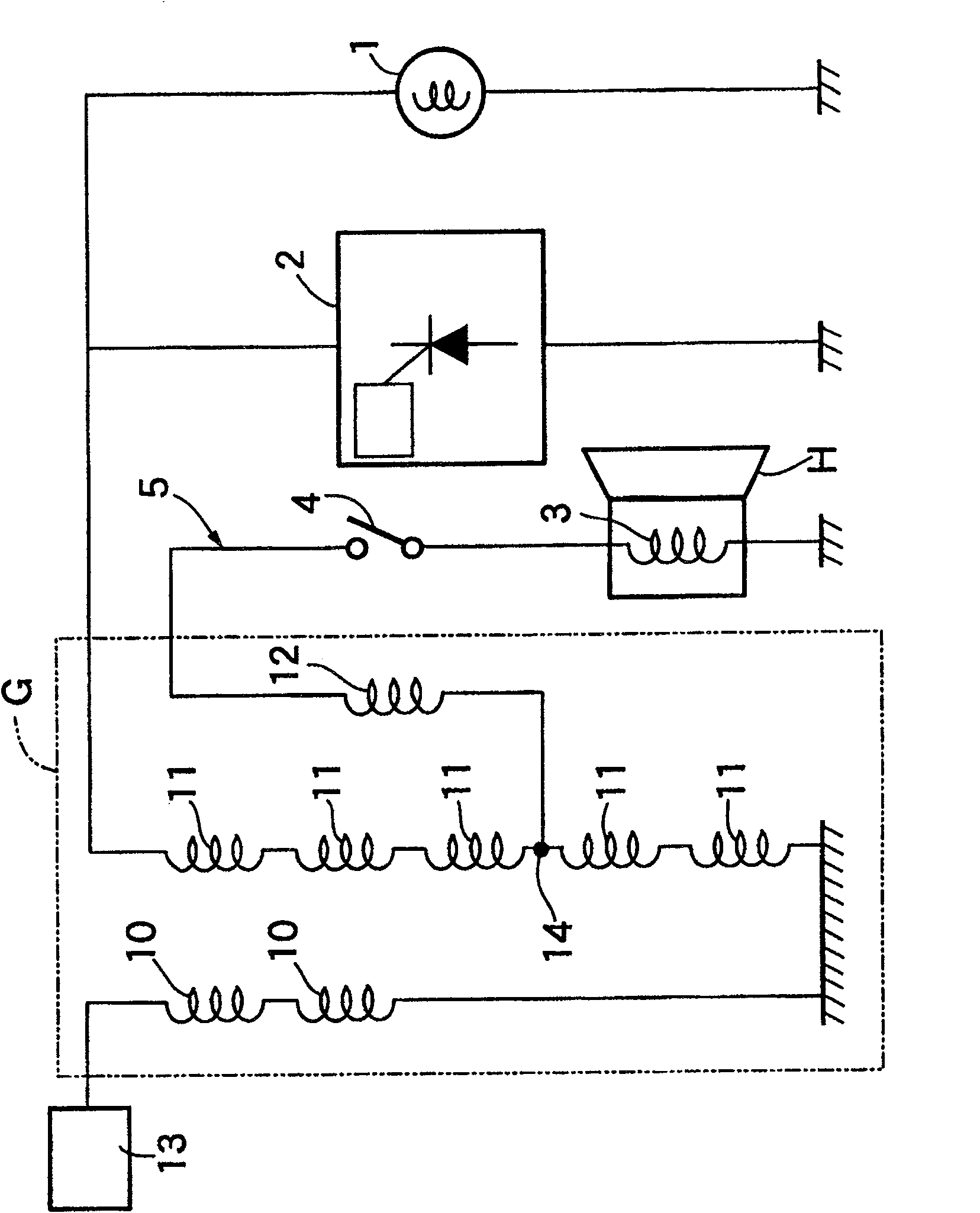

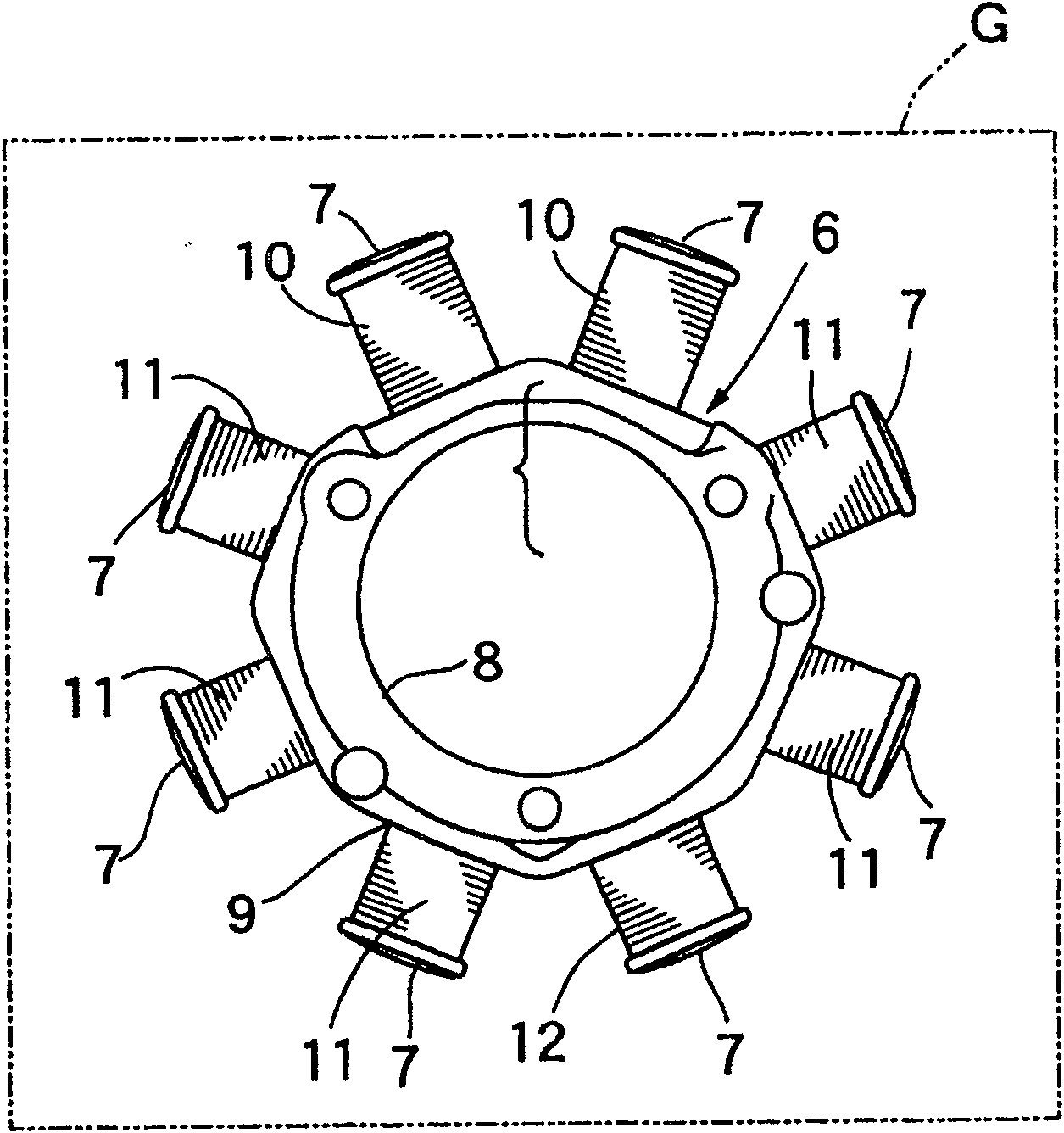

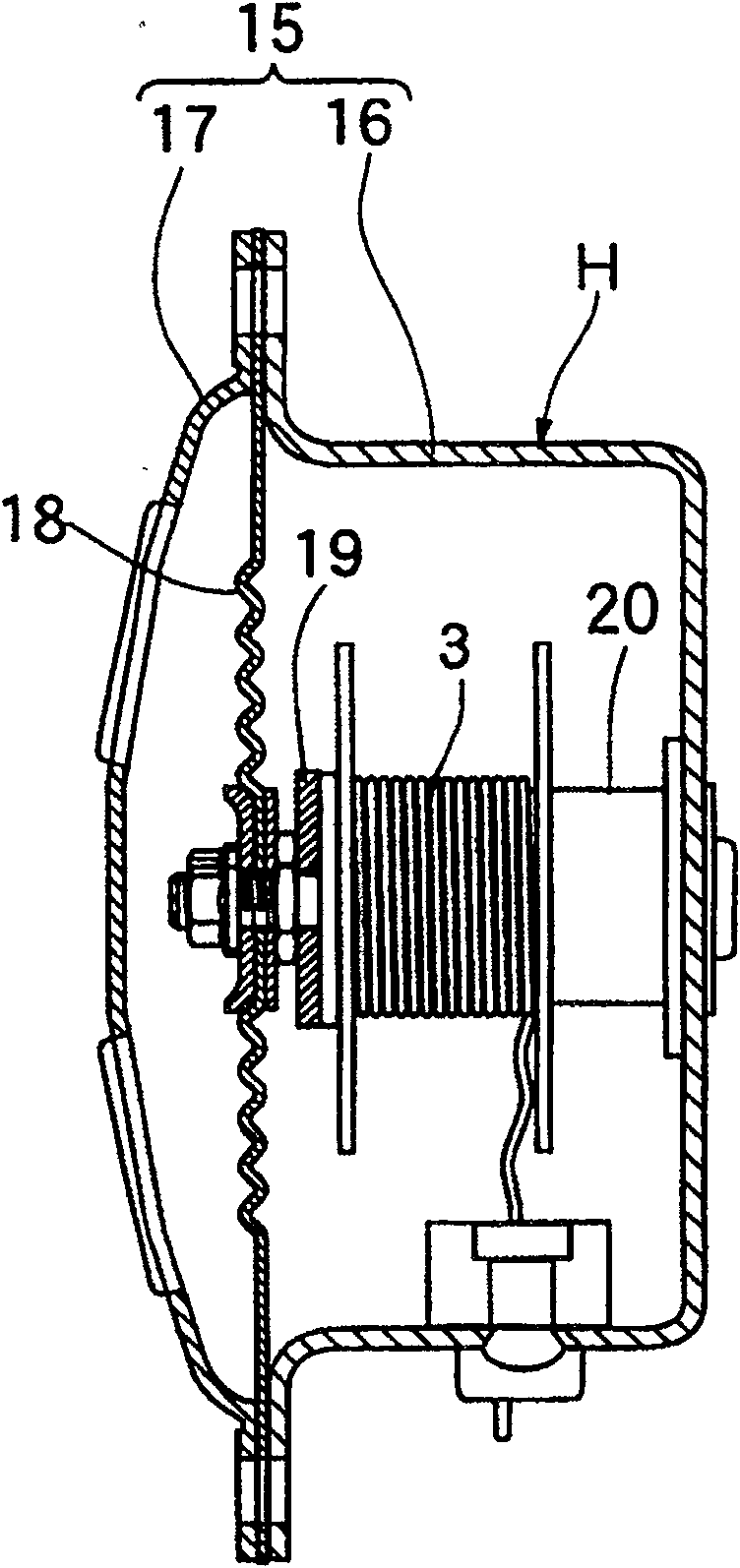

[0020] figure 1 It is a circuit diagram containing an AC speaker, figure 2 It is a front view of a stator included in a multi-pole alternator, image 3 is the longitudinal sectional view of the AC horn, Figure 4 It is a graph showing the field coil current supplied to the AC speaker in the rest state of the AC regulator in the low-speed rotation region when the electric load and the AC speaker are connected in parallel, Figure 5 It is a diagram showing the excitation coil current supplied to the AC speaker in the operating state of the AC regulator in the medium-speed rotation region when the electric load and the AC speaker are connected in parallel, Figure 6 It is a graph showing the field coil current supplied to the AC speaker in the operating state of the AC regulator when the electric load and the AC speaker are connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com