Exhaust recycled valve multi-functional test device

A technology of exhaust gas recirculation valve and test device, which is applied in the direction of measuring device, internal combustion engine test, machine/structural component test, etc. It can solve problems such as single function, poor portability, and inability to strongly support the research work of exhaust gas recirculation valve , to achieve the effect of reduced operating cost, reduced damage probability, convenient installation test and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

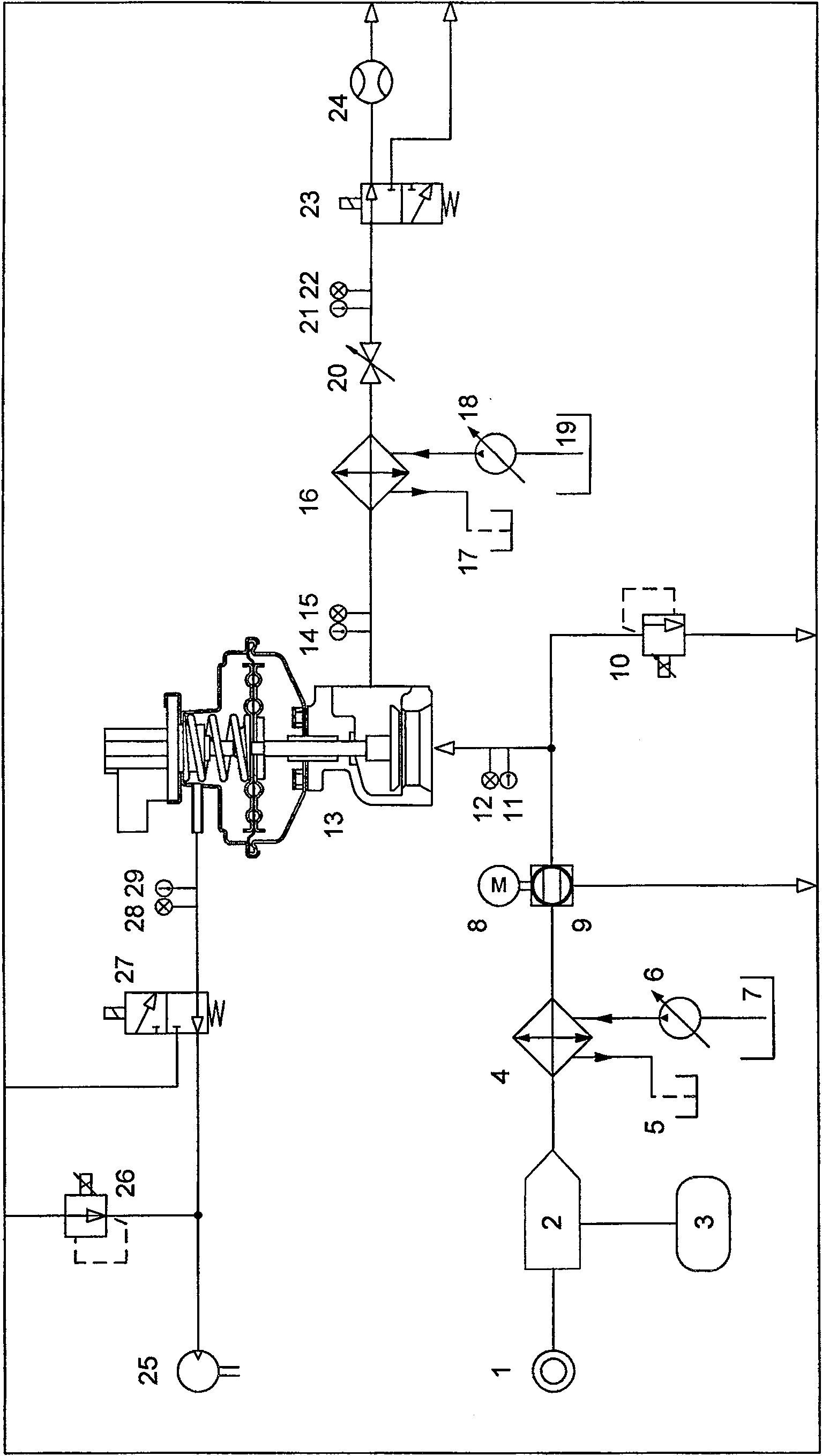

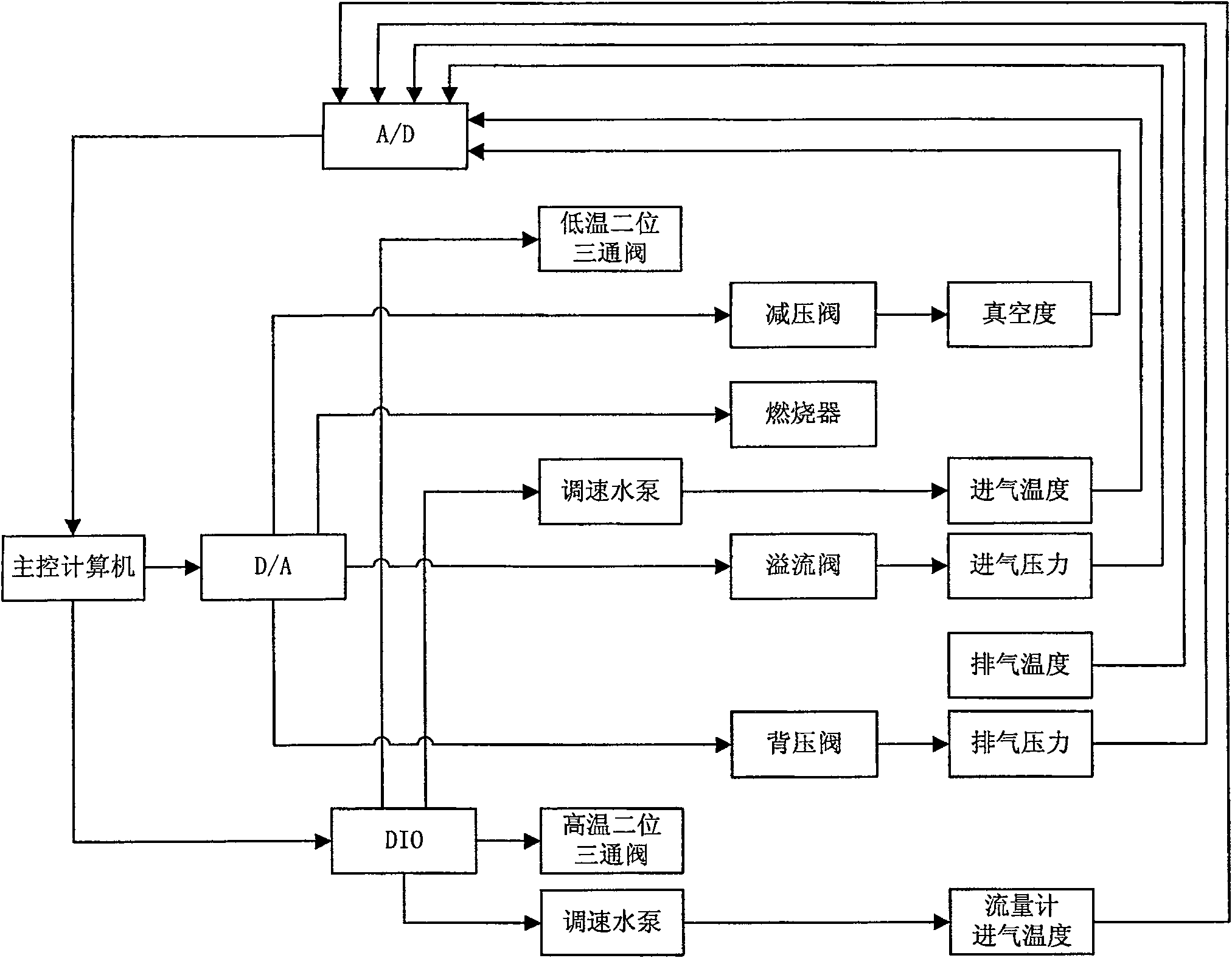

[0020] Such as figure 1 As shown, the gas outlet of the burner 2 in the EGR valve multifunctional test device is sequentially connected with the inlet cooler 4, the continuous rotary valve 9, one end of the overflow valve 10, and the gas inlet of the EGR valve 13 to be tested. Connect, the other air outlet of the continuous rotary valve 9 is open to the atmosphere, the air inlet of the vacuum pump 25 is connected with one end of the overflow valve 10, the normal temperature two-position three-way valve 27, and the vacuum tube of the exhaust gas recirculation valve 13 to be tested, One port of the normal temperature two-position three-way valve 27 is connected to the atmosphere, and the outlet of the exhaust gas recirculation valve 13 to be tested is connected with the exhaust cooler 16, the back pressure valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com