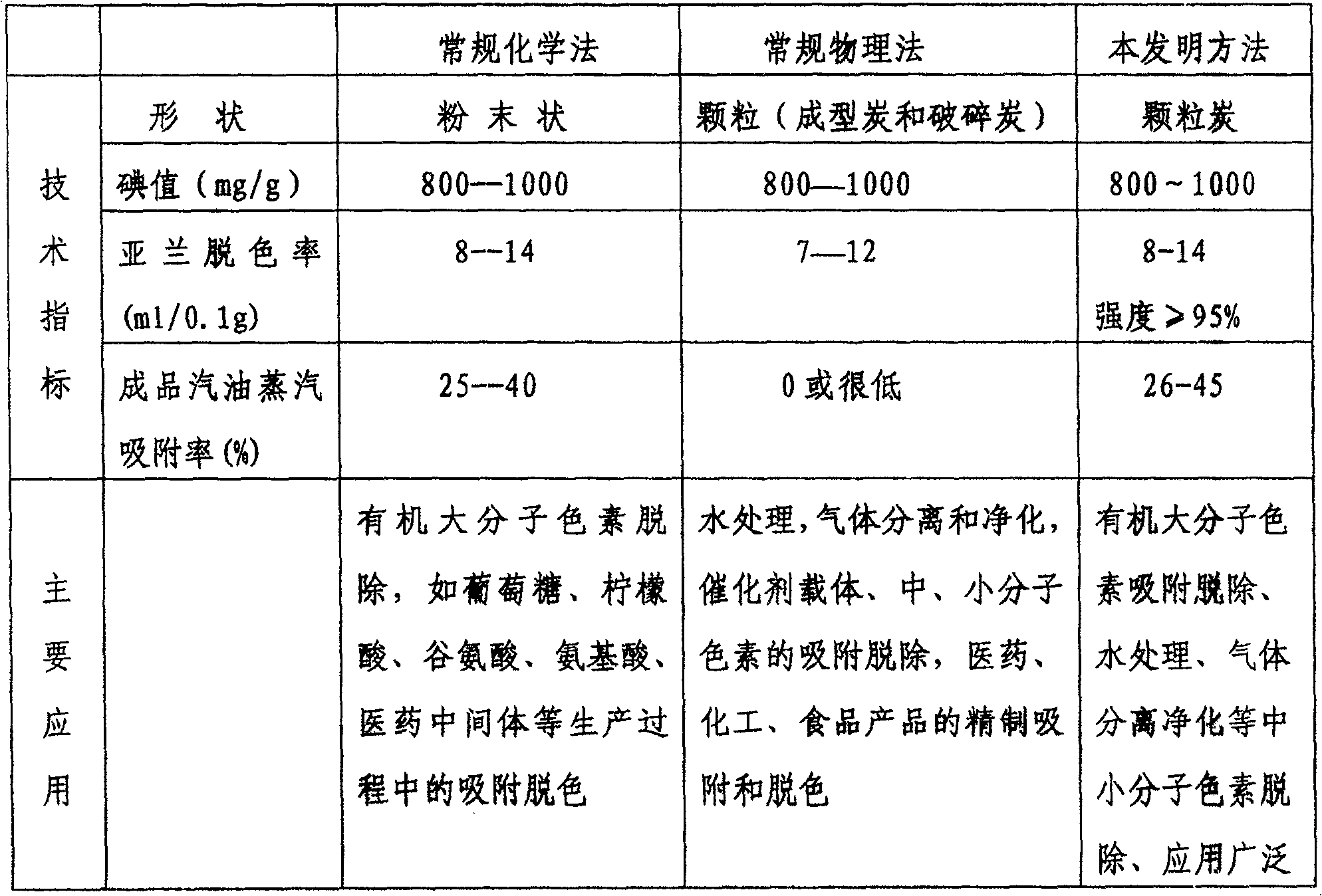

Special activated charcoal for gasoline vapor adsorption and preparation method thereof

A technology for adsorbing gasoline and activated carbon, applied in chemical instruments and methods, and other chemical processes, can solve the problems of unsatisfactory decolorization and adsorption performance, achieve excellent adsorption and decolorization performance, reduce adsorption and decolorization carbon consumption and sewage discharge, and high The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

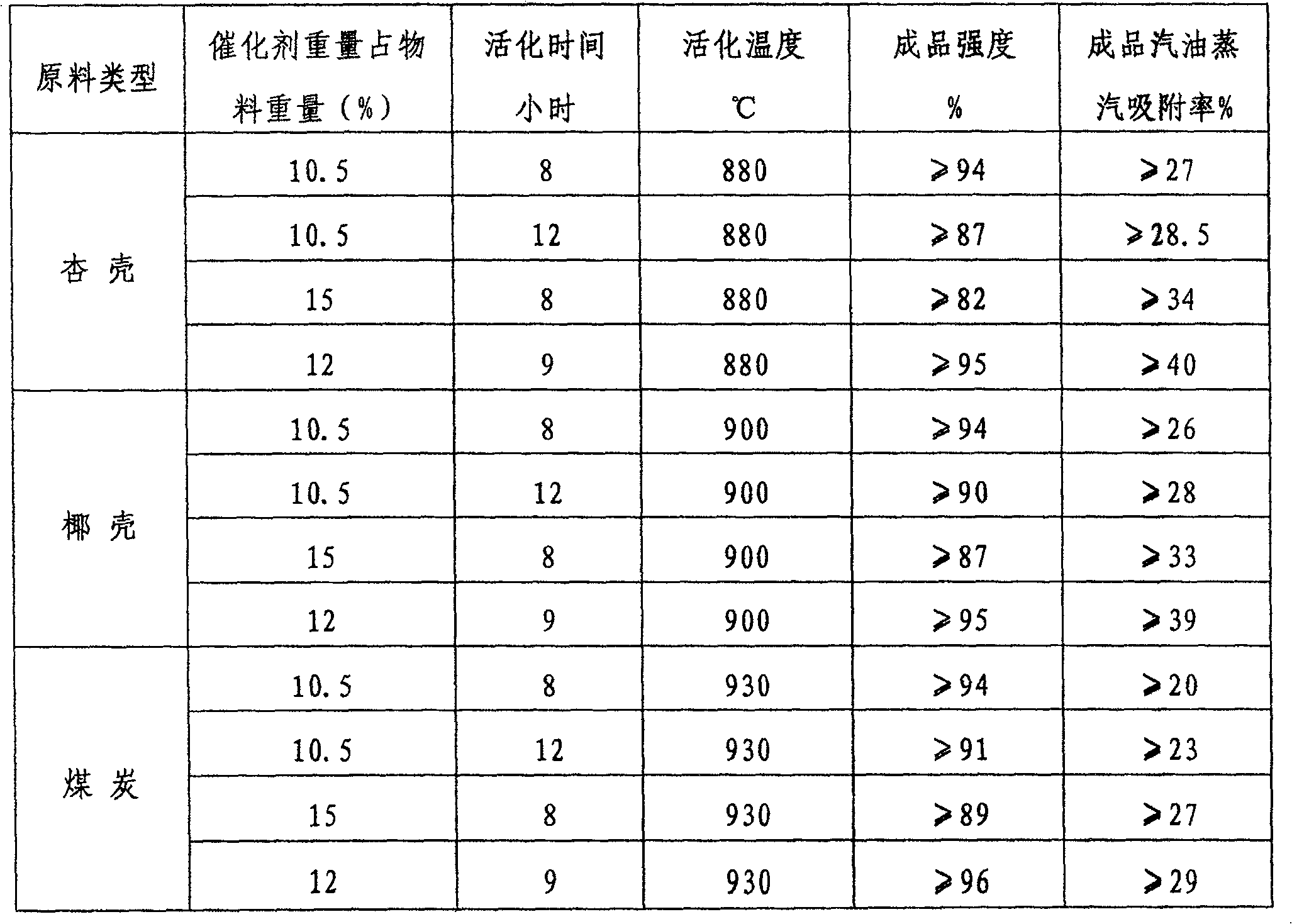

Embodiment 1

[0022] Embodiment 1: 100kg raw material apricot shells are put into carbonization furnace at 500 ± 50 ℃ of carbonization 2 hours, after being cooled to room temperature, carbonization material is put into dipping tank, with 5kg 85% phosphoric acid, 8kg magnesia and 100kg water, Prepare an impregnating aqueous solution, impregnate the carbonized material (the standard of the liquid level of the impregnated liquid is - subject to immersion in the carbon layer), soak at room temperature for 6-8 hours; then put the impregnated carbonized material in a drying oven at 400± Drying at 50°C; the carbonized material carrying the impregnation is activated at 800±50°C for 8 to 12 hours under the condition of passing overheated steam, and then the activated material is pickled with 10% hydrochloric acid aqueous solution. The material is dried at 400±50°C for 1 to 2 hours, and crushed to 20 to 60 mesh particles.

Embodiment 2

[0023] Example 2: Use wood tar as a binder and add coal powder to press into a columnar shape. Take 100kg of pressed material and carbonize it in a carbonization furnace at 500±50°C for 3 hours. After cooling to room temperature, put the carbonized material into a dipping tank. 5kg of 85% phosphoric acid, 10kg of magnesia and 100kg of water are prepared into an impregnating aqueous solution, impregnated with carbonized material (the standard of the liquid level of the impregnating solution is - subject to immersion in the carbon layer), and soaked at room temperature for 6 to 8 hours; The impregnated carbonized material is dried in a drying furnace at 400±50°C; the carbonized material carrying the impregnated material is activated for 8-12 hours at 800±50°C under the condition of passing through superheated steam, and then treated with 10% Pickle with hydrochloric acid aqueous solution, then dry at 400±50°C for 1-2 hours, and crush to 20-60 mesh particles.

[0024] Process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com