Apparatus direct mounting connector

A technology for installing equipment and connectors, which is applied in the direction of connection, parts of connecting devices, and structural parts of conversion equipment, etc. The effect of improving operability, improving connection operability and connection quality, and improving design freedom and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiment of the present invention will be described in detail below according to the accompanying drawings.

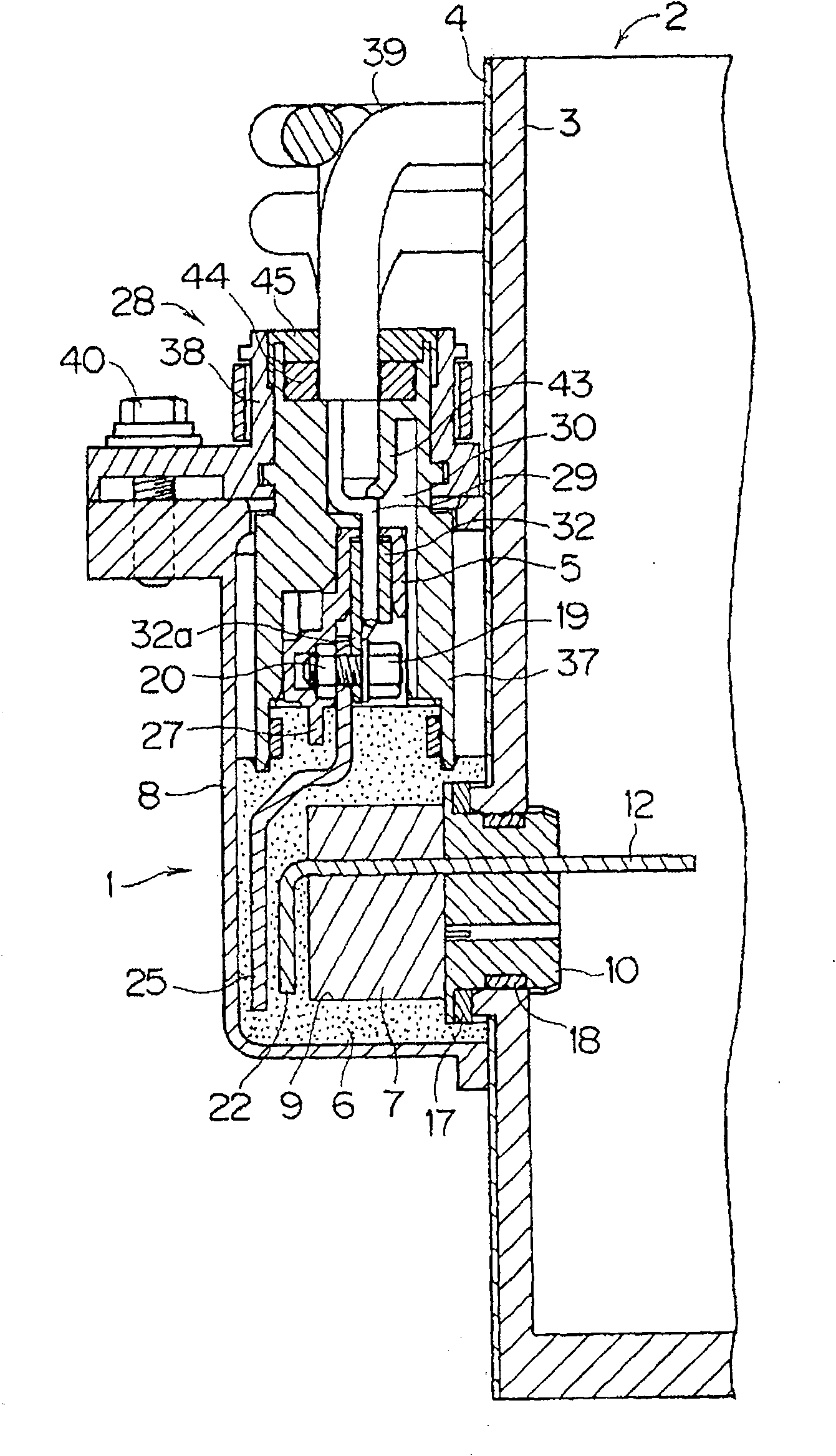

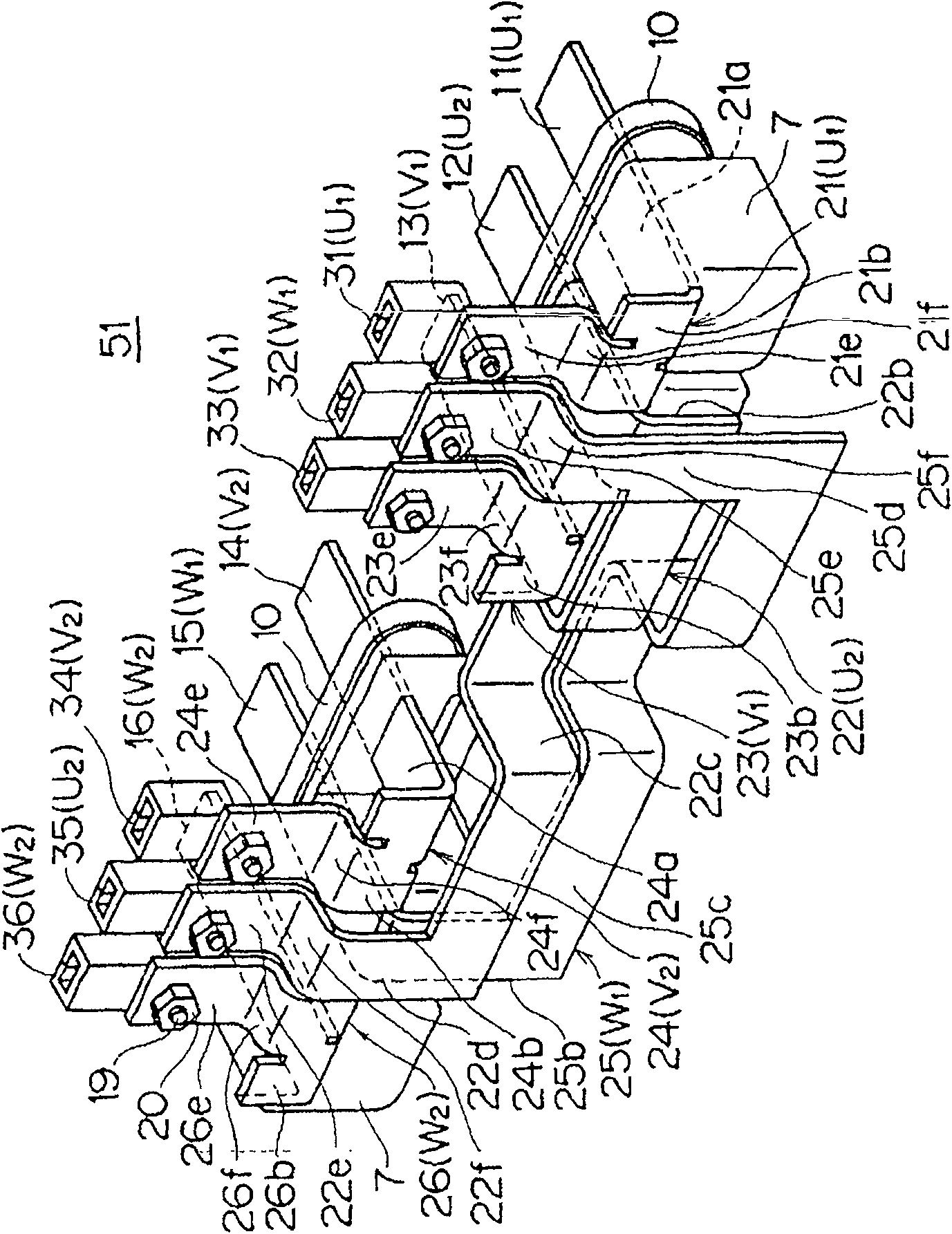

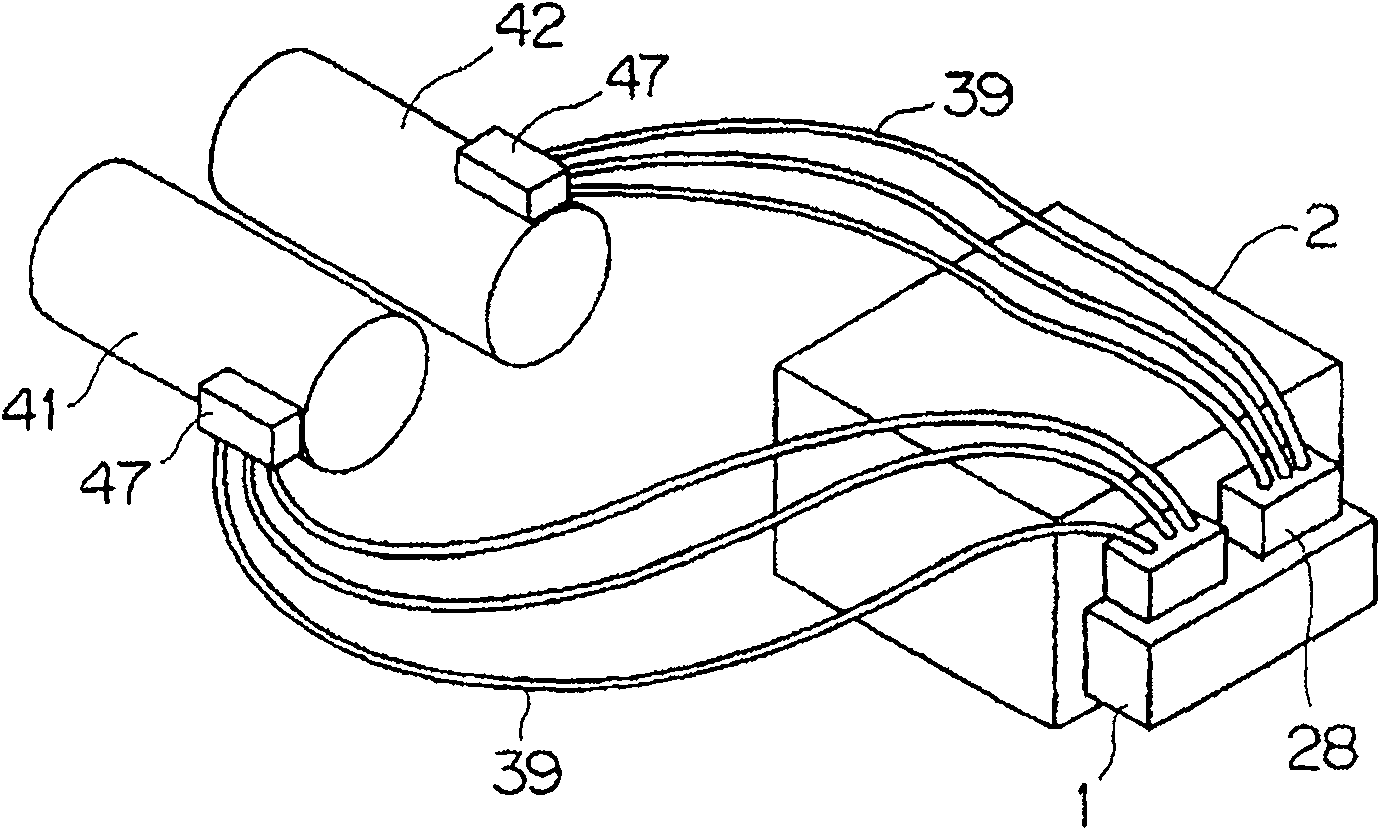

[0057] figure 1 Showing one embodiment of the connector for direct mounting equipment of the present invention, figure 2 An embodiment of a wiring structure of a bus bar to which a device connector is directly mounted is shown.

[0058] The direct mount device connector 1 has at least six terminal portions 11 to 16 ( figure 2 ) of six busbars 21-26; female terminals (terminal parts) 31-36 ( figure 2 ); housing 5 made of insulating resin for accommodating female terminals 31-36; insulating resin part (housing) 6 for insulating and fixing bus bars 21-26 by insert molding; current sensor 7 disposed in insulating resin part 6; covering insulation Resin part 6 and sealing cover 8 made of conductive metal of case 5 .

[0059] The terminal parts 11-16 of the six busbars 21-26 are arranged according to the pole sequence of UUVVWW, and each of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com