Large turn angle ball support

A corner ball, upper seat technology, applied in the direction of building, building structure, etc., can solve the problems of small horizontal force deformation, small turning angle, increased engineering cost, etc., to achieve the effect of improving sealing, reducing friction, and preventing oil spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

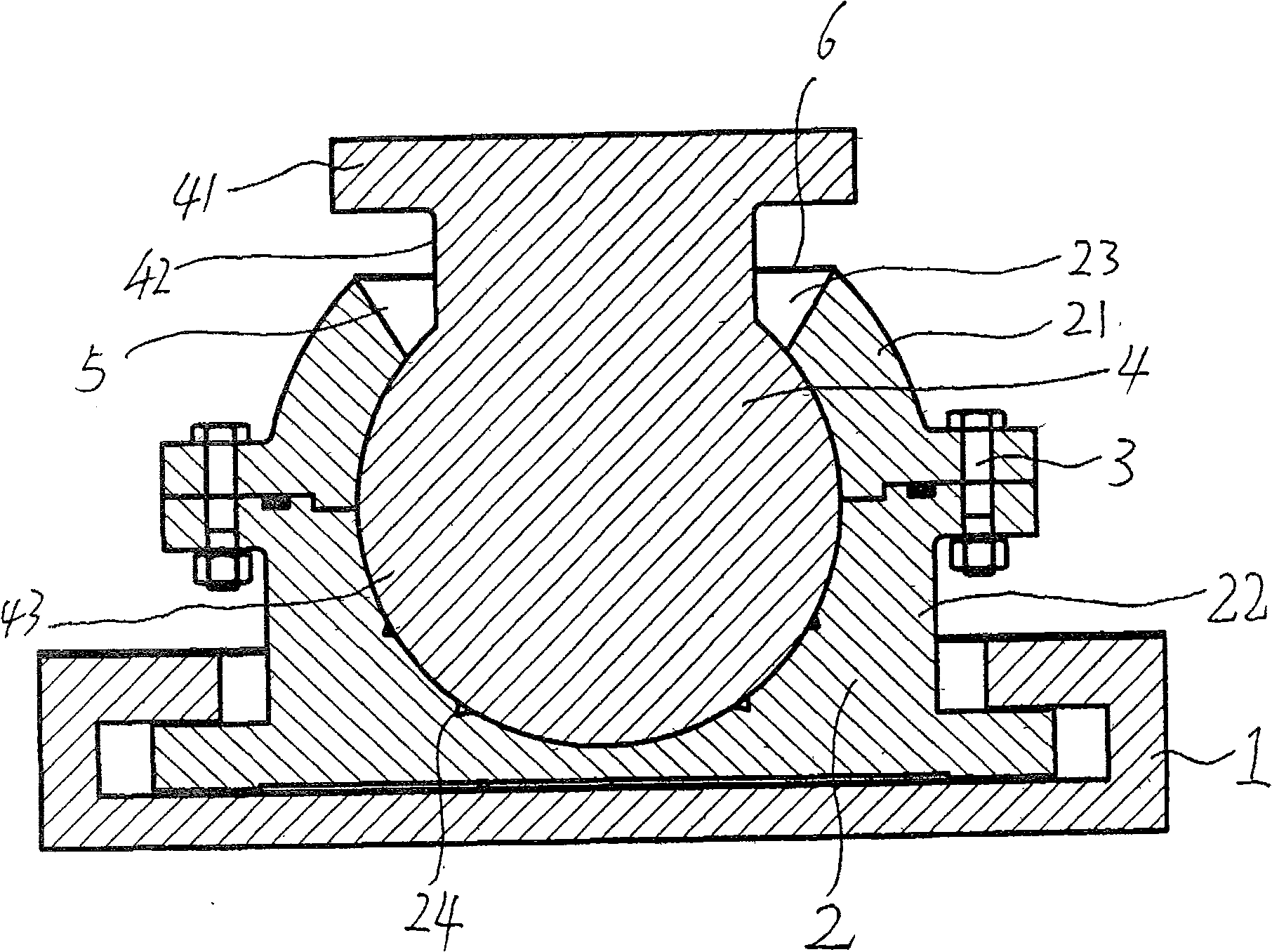

[0007] The structure and operating principle of a large-corner ball bearing of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0008] As shown in the accompanying drawings, it is a structural schematic diagram of a longitudinal section of a large corner ball bearing of the present invention. A large corner ball bearing of the present invention includes a box body 1 and a base 2 in the box body. The inner wall of the base 2 is a spherical surface with an upper seat plate opening 23 on the upper part. The base 2 is composed of an upper base 21 and a lower base 22. The upper base 21 and lower base 22 are connected together by screw rod 3, and upper seat plate 4 is arranged in base 2, and upper seat plate 4 comprises upper seat plate shoulder 41, upper seat plate waist 42 and upper seat plate lower shoulder 43, upper seat plate shoulder 41 is a square plate shape, the upper seat plate waist 42 is cylindrical, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com