Piezo crystal drive high speed switch valve

A technology of high-speed switching valves and piezoelectric crystals, applied in fluid pressure actuators, lifting valves, valve details, etc., can solve the problems of sensitive output displacement temperature changes, low output displacement, etc., and achieve high working pressure and load capacity Strong, high frequency response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

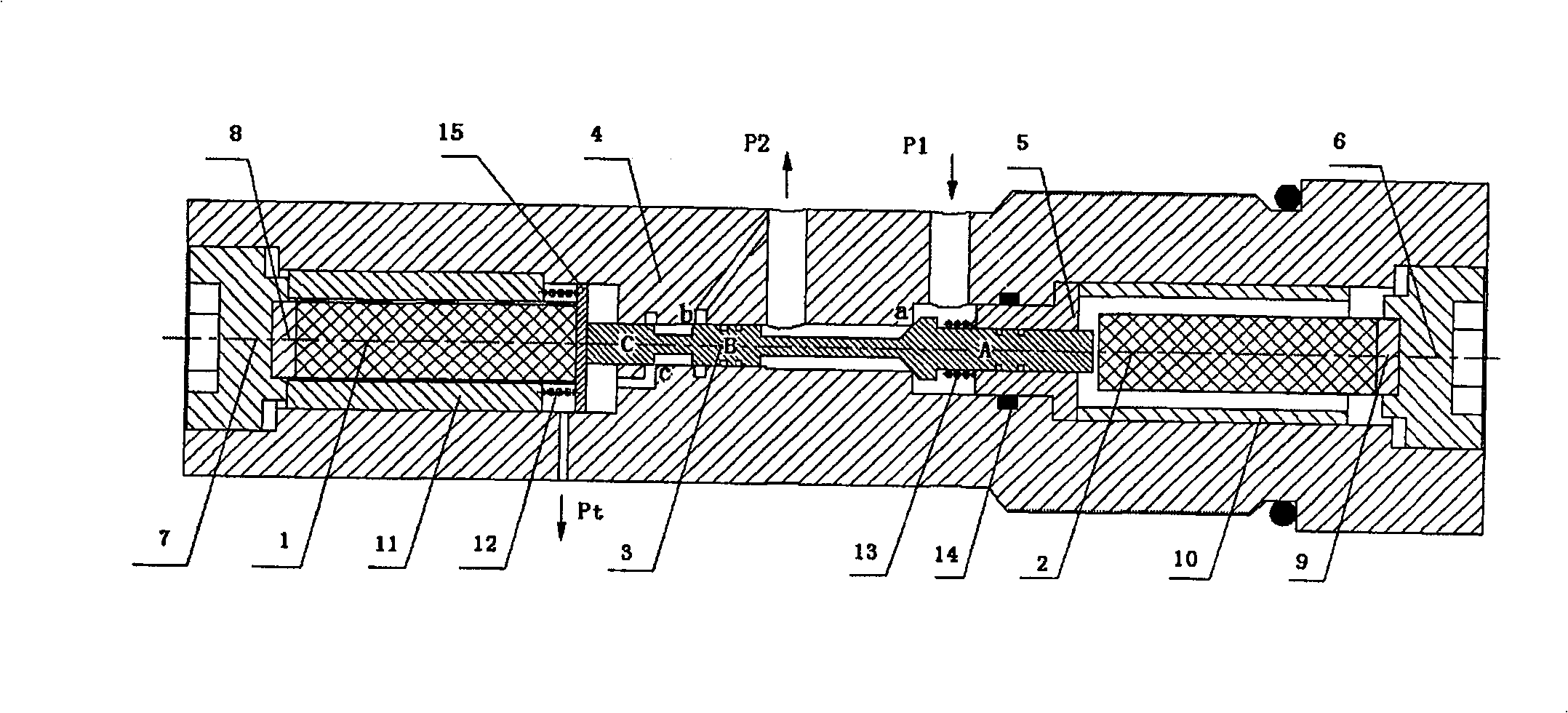

[0023] As shown in the accompanying drawings, the present invention is provided with a first driver casing 10 in one end hole of the valve body 4, and a first piezoelectric crystal 2 is housed in the first driver casing 10, and the first piezoelectric crystal 2 is close to an end of the outer side of the valve body 4. The first heat-shrinkable sheet 9 is installed, the first heat-shrinkable sheet 9 is embedded in the first end cover 6, and the valve sleeve 5 is installed in the hole of the valve body 4 at the other end of the first piezoelectric crystal 2; the hole at the other end of the valve body 4 A second driver jacket 10 is housed in the second driver jacket 10. A second piezoelectric crystal 1 is housed in the second driver jacket 1. A second heat shrinkable sheet 8 is installed on the end of the second piezoelectric crystal 1 near the outer side of the valve body 4. The second thermal Shrink sheet 8 is embedded in the second end cover 7, and the other end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com