Laser cutting device

A cutting device and laser technology, applied in auxiliary devices, welding/cutting auxiliary equipment, laser welding equipment, etc., can solve problems such as substrate deformation, adjustment of laser spot size and shape, and inability to remove coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

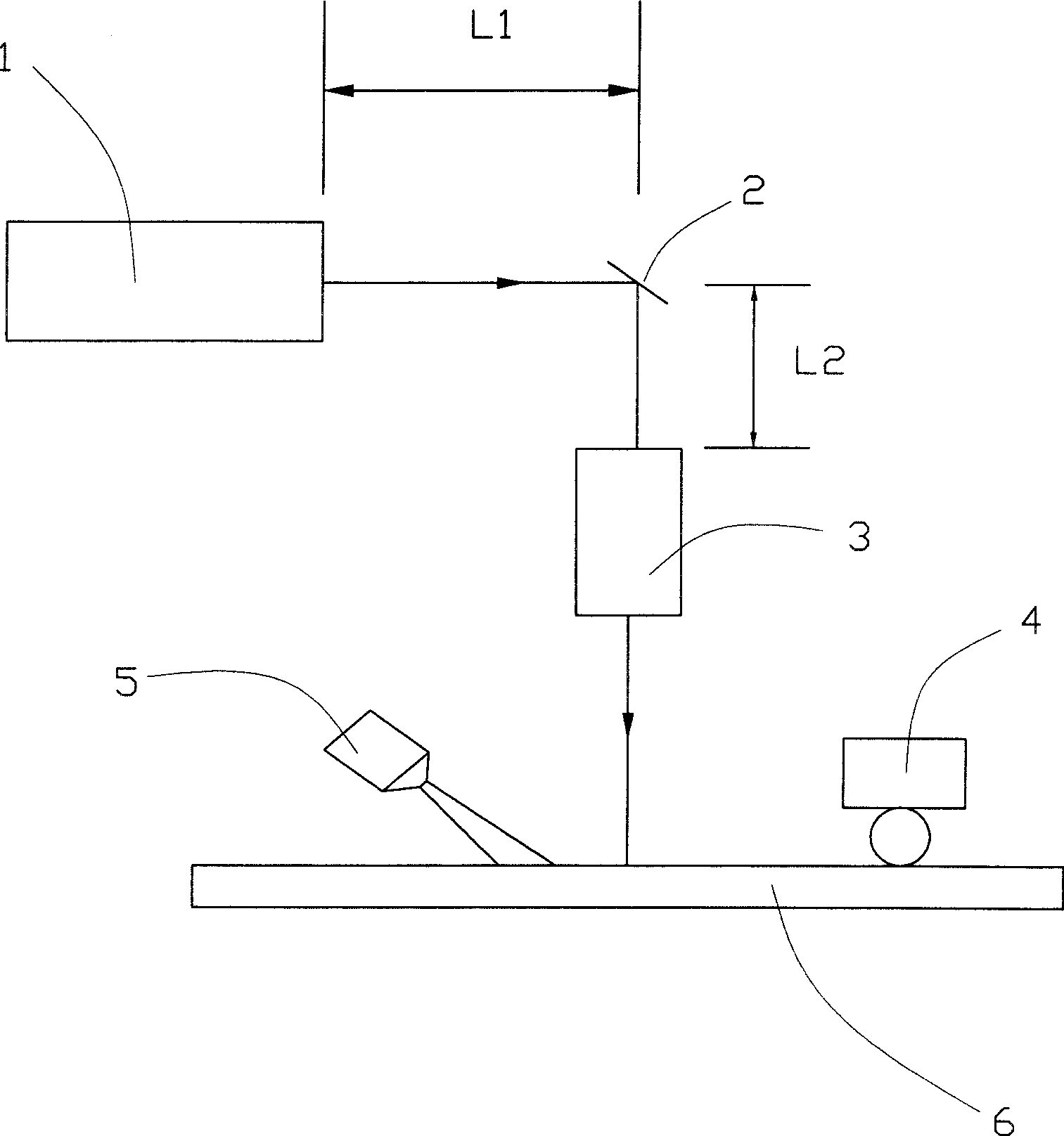

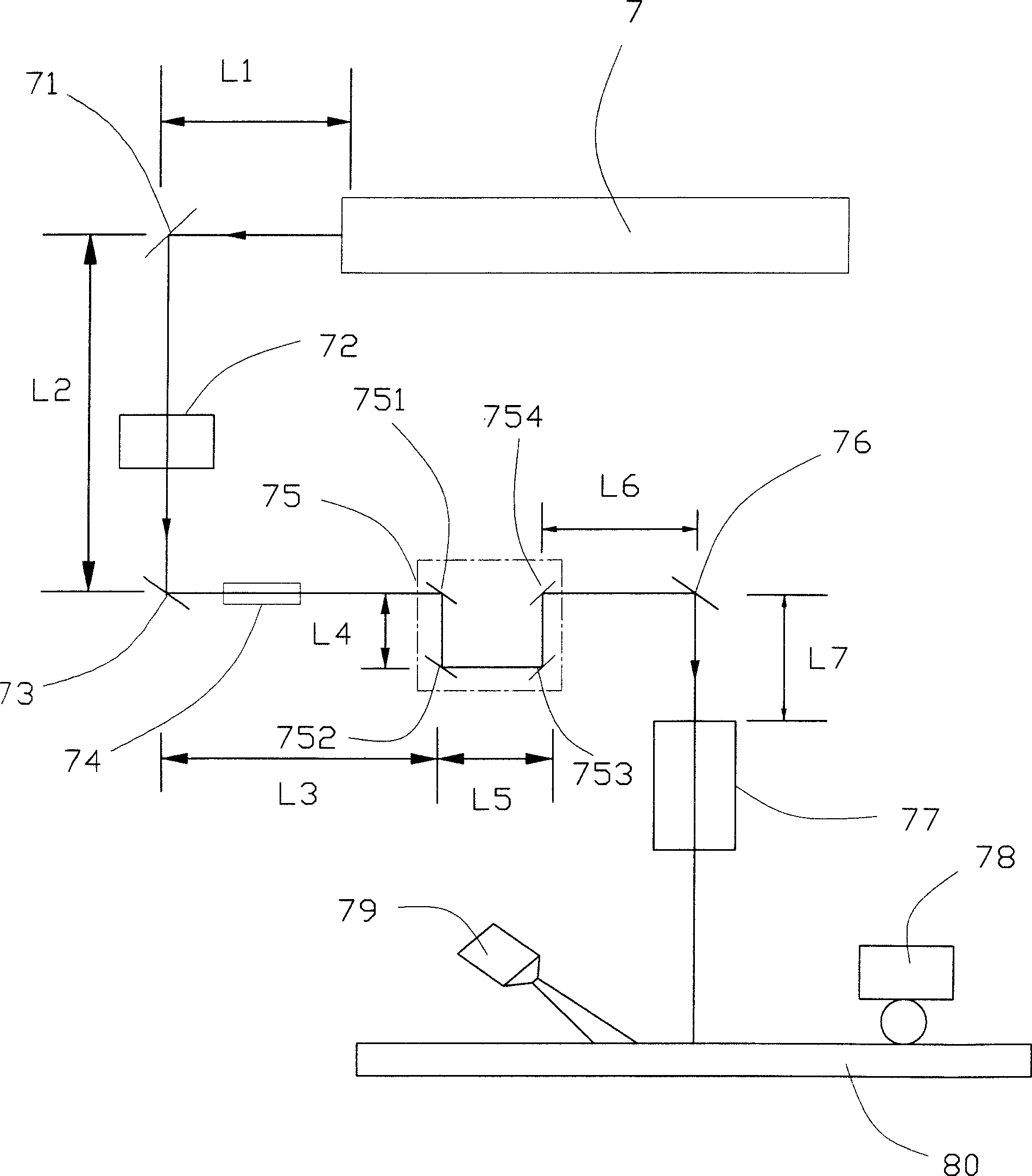

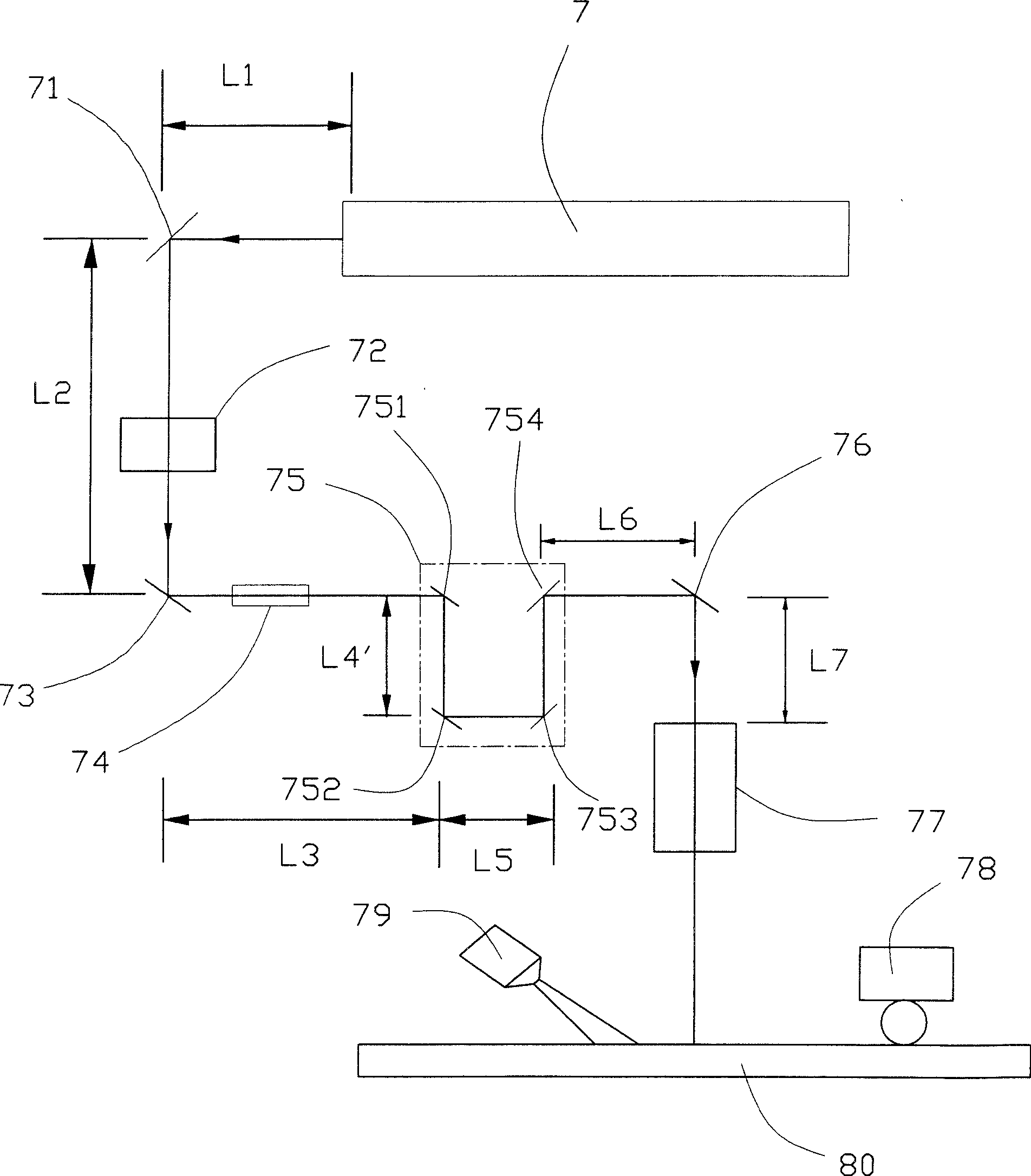

[0021] Such as figure 2 and image 3 As shown, the laser cutting device of the present invention is used for cutting brittle substrates (not shown), which includes a pre-cutting system 78 , a laser light system and a cooling system 79 . Above-mentioned laser optical system comprises the laser cavity 7 for producing laser light, the first reflection mirror 71, photointerrupter 72, the second reflection mirror 73, collimator (Collimator) 74, optical distance adjustment system 75, the first Three reflective mirrors 76 and a focusing lens group 77 . The laser cavity 7 generates laser light, and in the present invention, the laser light is carbon dioxide laser light. After the laser light is emitted from the laser cavity 7, it is reflected by the first reflector 71 and passes through the photointerrupter 72 to the second reflector 73, and after being reflected by the second reflector 73 and entering the collimator 74, the laser light becomes a parallel beam. Then the laser ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com