Thin film applied technology for cold transfer printing fixation

A technology of cold transfer printing and application method, applied in the field of printing and dyeing industry, can solve the problems such as decrease in fixing rate, discoloration, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The plastic film is selected as polyethylene film (PE).

[0013] Specifications: 0.02mm thickness, 1.6~1.8m width, each roll is 1000m long, and the transfer fabric width is 1.5m.

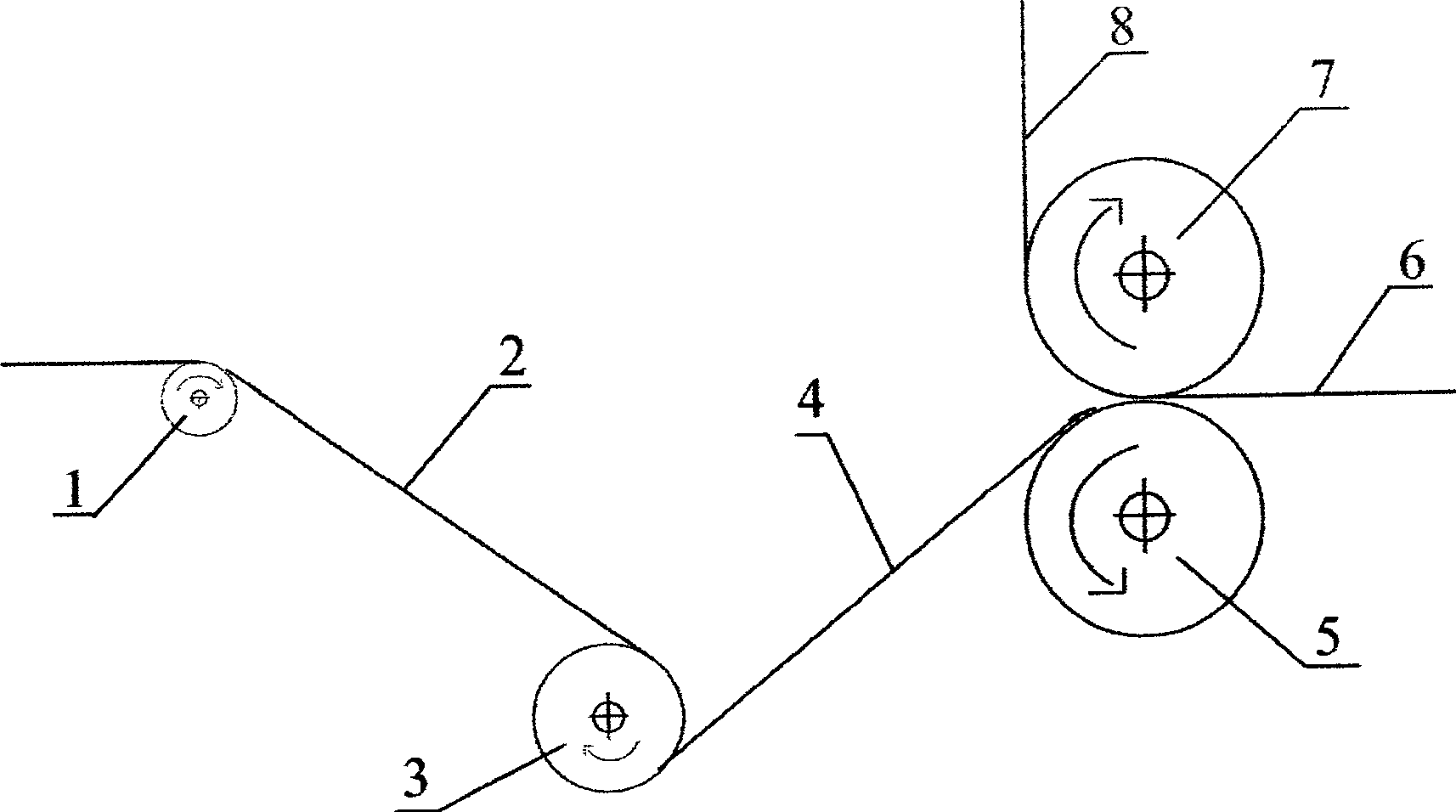

[0014] See figure 1 As shown, on the cold transfer printing machine, the rolled polyethylene plastic film 2 is placed on the inflatable shaft of the transfer printing machine fixed frame. During transfer printing, the plastic film 2 is fed synchronously through the guide roller 1 and passes through the fabric printing surface 4 printed on the main two rolls 7 and 5. The printed surface is closely bonded, moves with the fabric, and is rolled on the transfer printing machine. Take the frame 3 and wind it together into a reel, then seal the two ends of the film and the fabric with adhesive tape, and wrap the film to seal the outer layer of the fabric. In this way, when the fabric is rolled, it is not easy to cause cross-contamination and contamination of the printed pattern, and it is steamed ...

Embodiment 2

[0016] The plastic film is selected as a polypropylene film (PP) film.

[0017] Specifications: 0.05mm thickness, 1.6-1.8m width, 50kg per roll, about 800 meters long, 1.5m width of transfer fabric.

[0018] See figure 1 As shown, on the cold transfer printing machine, the rolled polypropylene plastic film 2 is placed on the inflatable shaft of the transfer printing machine fixed frame. During the transfer printing, the plastic film 2 is fed synchronously through the guide roller 1 and passes through the transfer printing surface 4 of the fabric transfer surface 4 after the main two rollers 7 and 5 are transferred. Take the frame 3 and wind it together into a reel, then seal the two ends of the film and the fabric with adhesive tape, and wrap the film to seal the outer layer of the fabric. In this way, when the fabric is rolled, it is not easy to cause cross-contamination and contamination of the printed pattern, and it is steamed and baked to fix the color, or the reel is r...

Embodiment 3

[0022] The plastic film is selected as low-density polyethylene.

[0023] Specifications: blow molding grade IPE--0.05mm thickness, width 1800mm, 20Kg / roll, transfer fabric width 1.65m.

[0024] See figure 1 As shown, on the cold transfer printing machine, the rolled low-density polyethylene plastic film 2 is placed on the inflatable shaft of the transfer printing machine fixed frame. During the transfer printing, the plastic film 2 is fed synchronously through the guide roller 1 and passes through the transfer printing surface 4 of the fabric transfer surface 4 after the main two rollers 7 and 5 are transferred. Take the frame 3 and wind it together into a reel, then seal the two ends of the film and the fabric with adhesive tape, and wrap the film to seal the outer layer of the fabric. In this way, when the fabric is rolled, it is not easy to cause cross-contamination and contamination of the printed pattern, and it is steamed and baked to fix the color, or the reel is rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com