Function expansion method for plasma digital control cutting machine

An expansion method and plasma technology, applied in the field of equipment function expansion and transformation, can solve the problems affecting the use effect and scope of the cutting machine, the limited length of the cutting plate, and the inability to fully meet the on-site use, etc., so as to improve the dust removal effect and reduce the difficulty of alignment. , Improve the effect of alignment accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It will be described below in conjunction with the accompanying drawings.

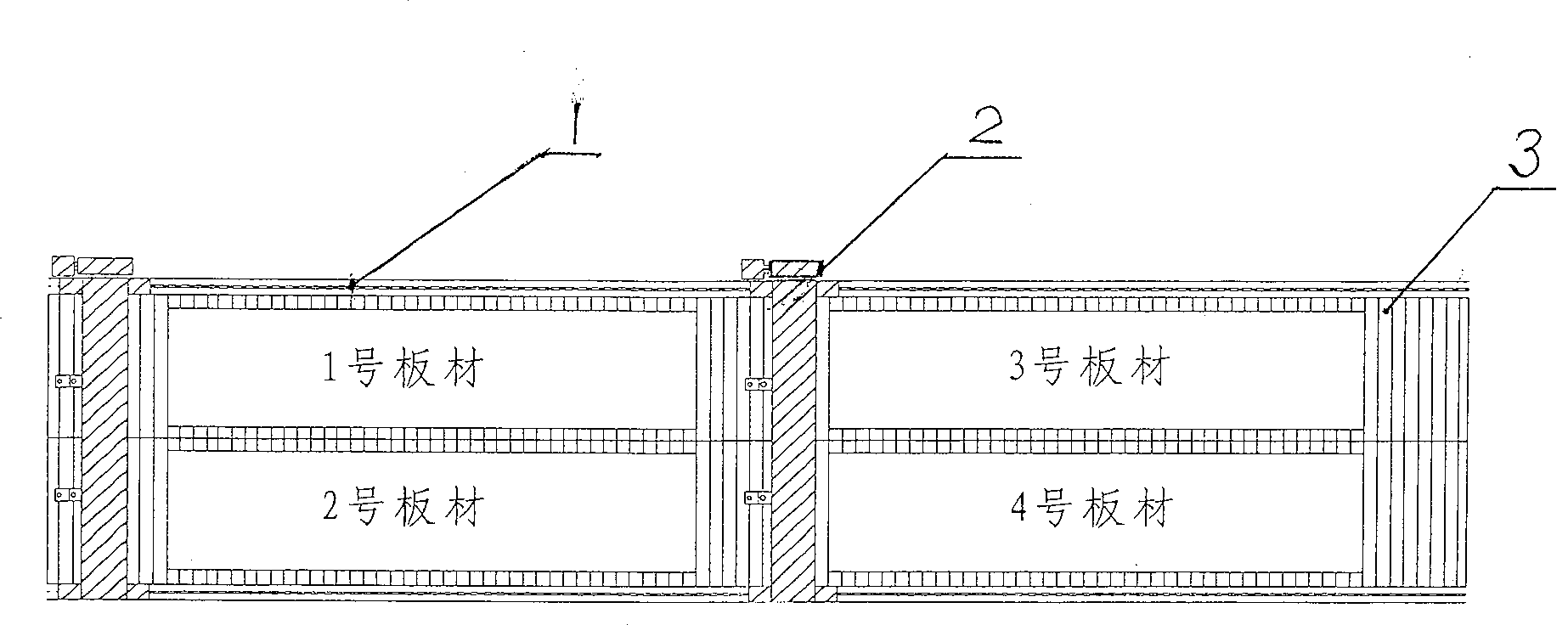

[0015] like figure 1 As shown, the plasma numerical control cutting machine that the present invention adopts is made up of track 1, body 2, platform 3, and its total length is 32m, and width is 7.5m. sheet. When the double head cuts two boards symmetrically, the other half of the platform can perform numbering, sorting, lower board and upper board at the same time. In addition, it can also complete tasks that could not be done before, such as the paneling of super-long and super-wide plates, thereby saving labor time and greatly improving labor efficiency.

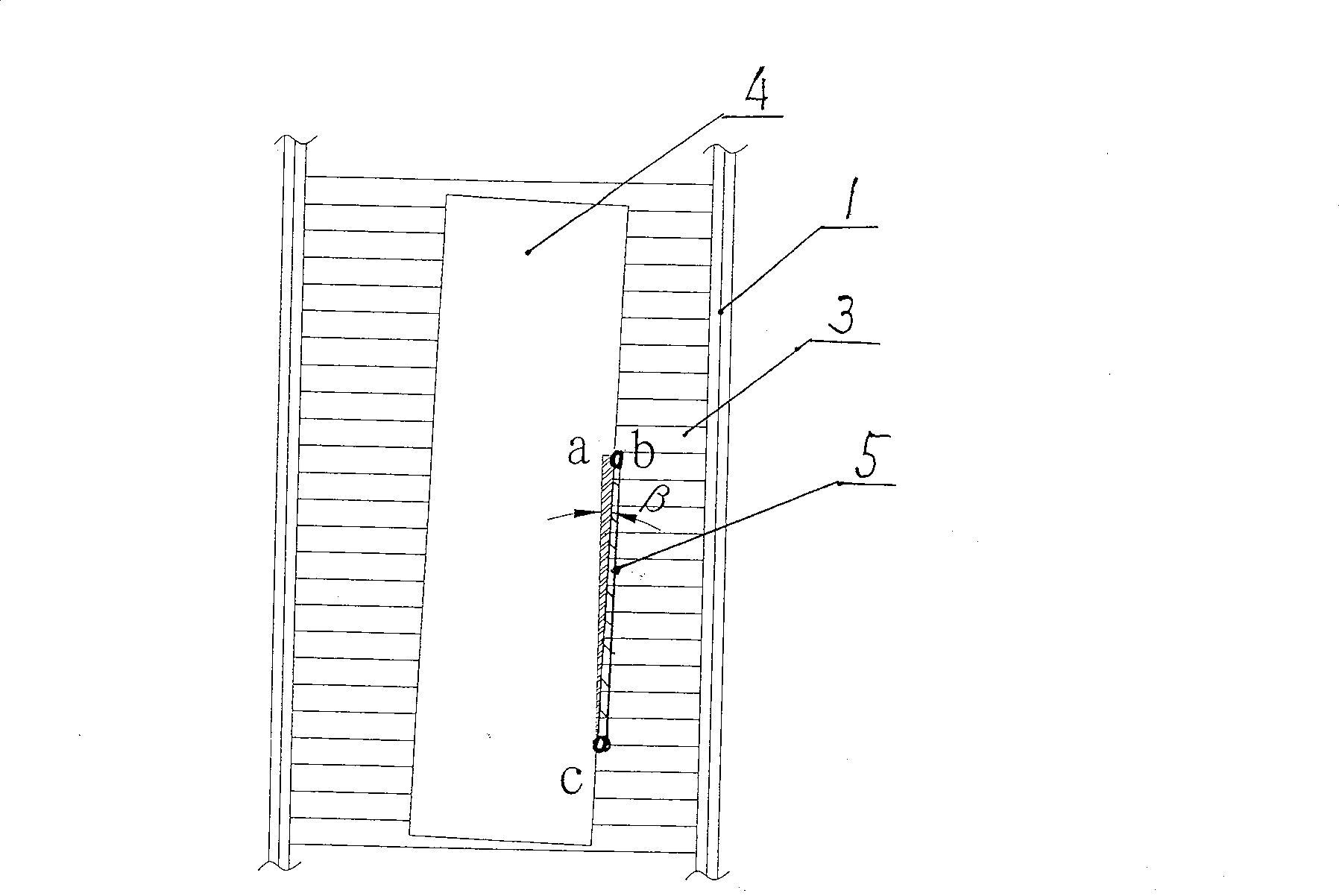

[0016] like figure 2 As shown, the plate inclination aligner 5 is placed on the side of the plate 4, and the tangent value of the inclination angle of the plate relative to the track can be obtained by measuring the lengths of the line segments ab and ac, and then the size of the angle can be obtained by calculating the arc tangent . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com