Power conversion system

A technology for converting system and power, which is applied in the direction of output power conversion device, control system, irreversible DC power input to AC power output, etc., to achieve the effect of miniaturization, reduction and suppression of voltage fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]

The power conversion system of the present invention will be described in detail below based on the illustrated embodiments.

[0022]

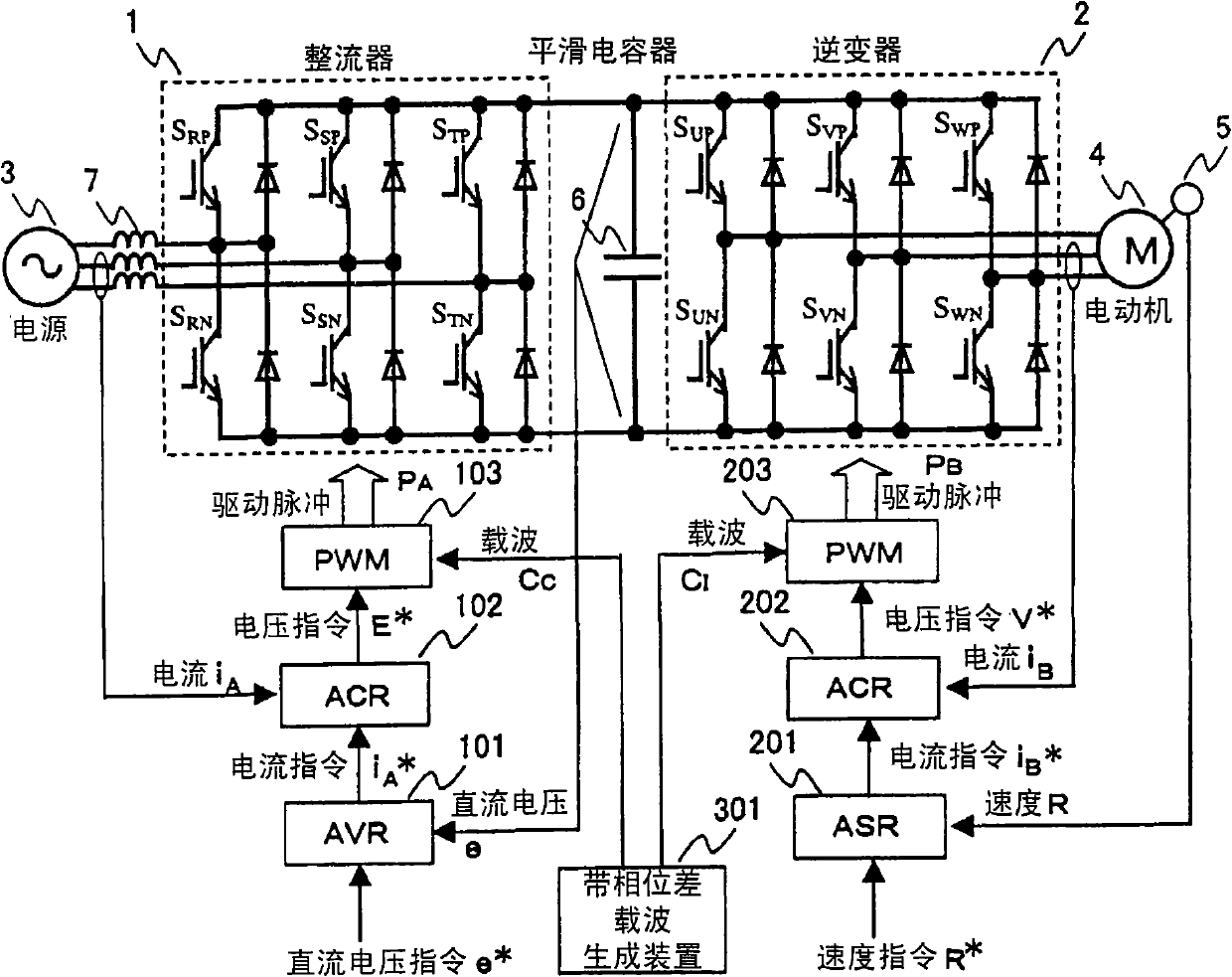

Fig. 1 shows an embodiment of the present invention, in the figure, 301 represents the generator with phase difference carrier, can generate the carrier CC with triangular waveform and the triangular waveform with certain phase difference Δ with respect to this carrier CC by this carrier generator There are two types of carriers, namely carrier CI, and these carriers can be supplied to PWM103 and PWM203, respectively. In addition, other structures are the same as those of the power conversion system in the prior art shown in FIG. 8 and FIG. 9 .

[0023]

Also, in the embodiment shown in FIG. 1 , the voltage across the terminals of the smoothing capacitor 6 is firstly fed back as a DC voltage e on the rectifier 1 side, and the current command iA* on the power supply side is generated by the AVR 101 so that the DC voltage e and DC The vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com