Magnetic flux concentrating motor

一种通量集中、磁通泄漏的技术,应用在制造电动发电机、电动组件、机电装置等方向,能够解决外伸部分失去作用等问题,达到提高总体性能、扭矩提高、提高扭矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

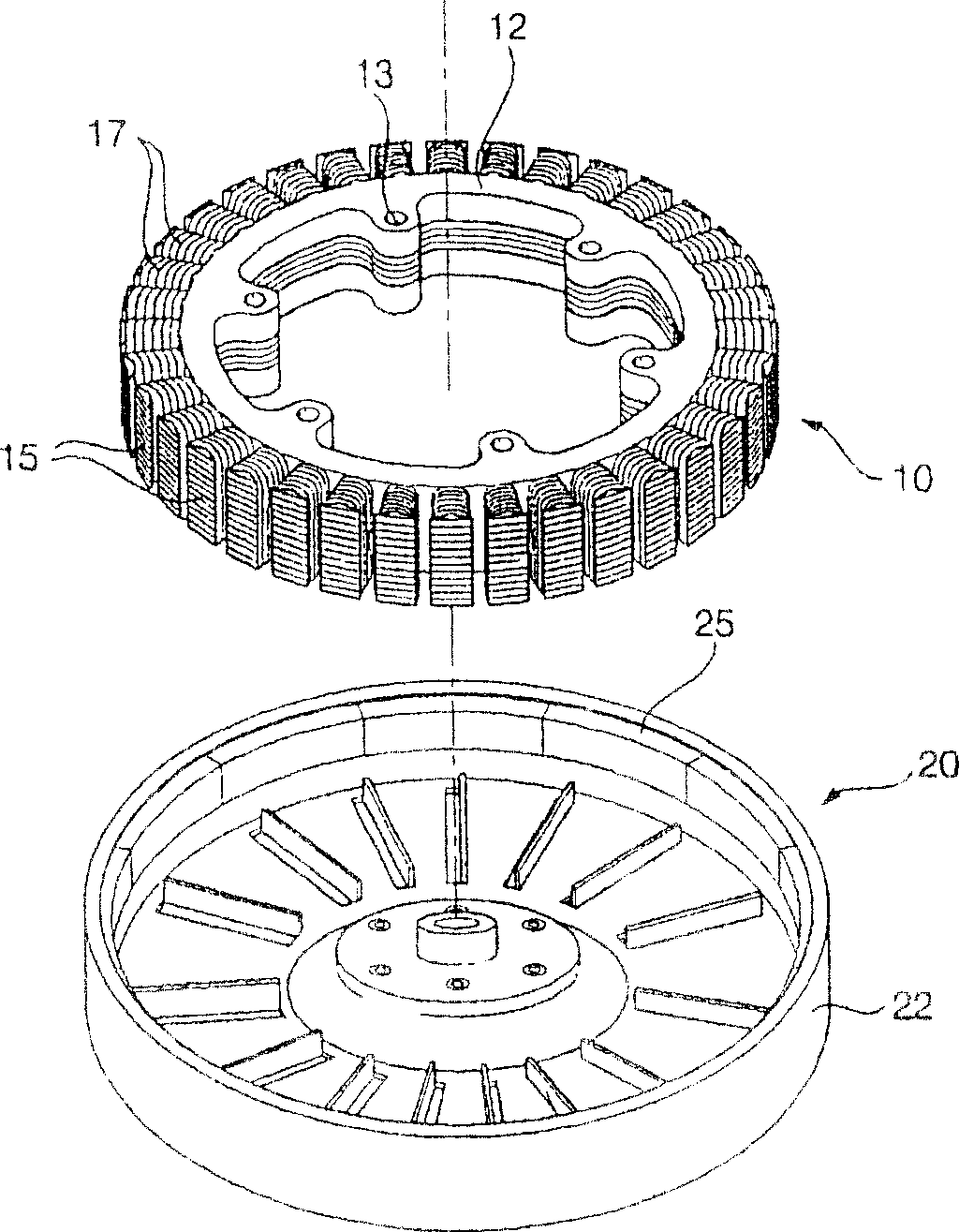

[0036] Now, a preferred embodiment of the permanent magnet motor of the present invention will be described in detail with reference to the accompanying drawings.

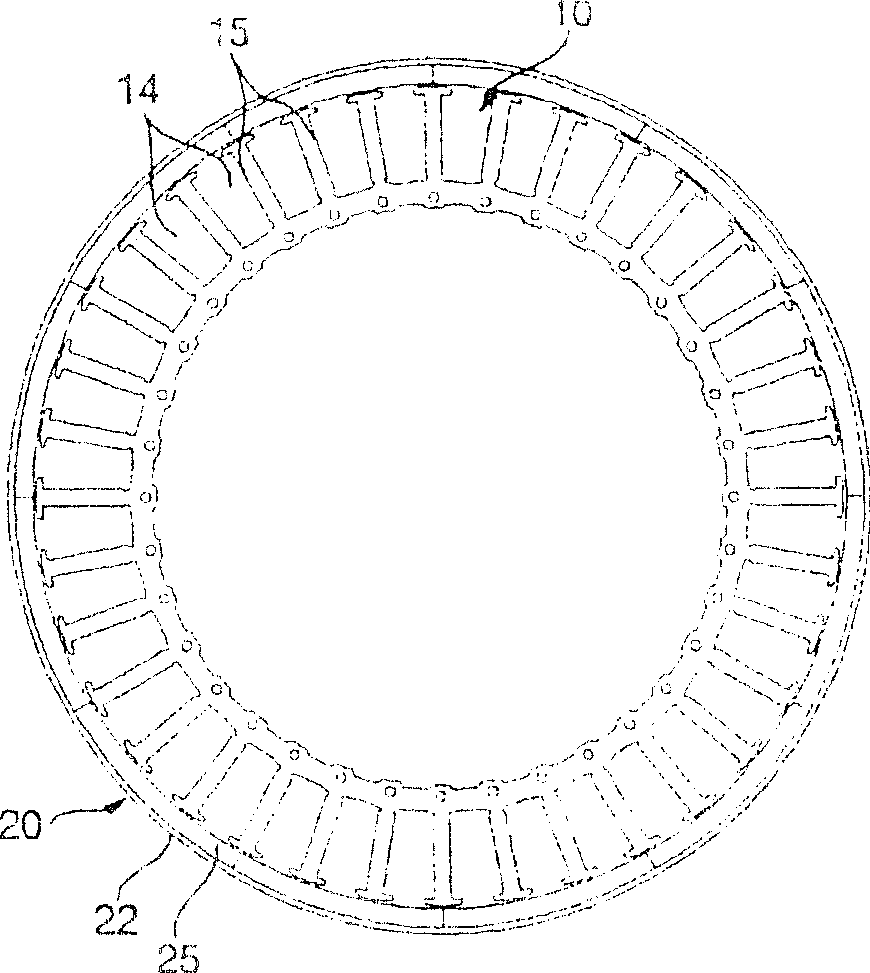

[0037] Figure 5 is a plan view of a flux-concentrated motor according to the present invention.

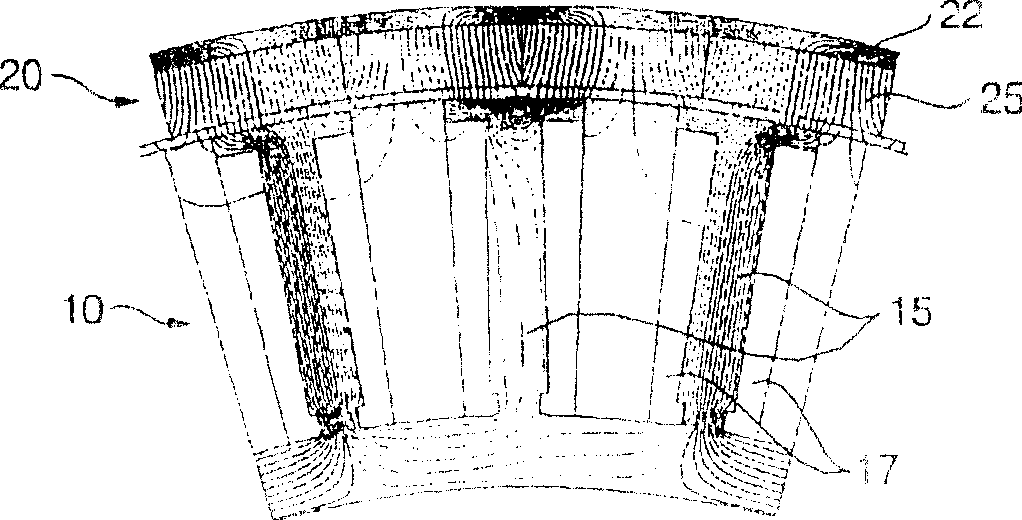

[0038] The flux-concentrated motor of the present invention includes: an annular stator 50 formed with a plurality of teeth 53 and coils 55 wound on the teeth 53 in the radial direction; and a rotor 60 located at the center of the stator 50, including a A plurality of magnets in the circumferential direction, whereby the magnets have poles of the same polarity facing each other, and the rotor rotates by interaction with the coil 55 of the stator 50 .

[0039] The stator 50 includes: an annular iron core 51 formed on an outer surface; a plurality of teeth 53 protruding from an inner circumferential surface of the iron core 51 toward the rotor 60 and arranged in a radial direction; and coils 55 wound on corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com