Low-gravity golf head structure

A golf club head and low center of gravity technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of reducing the weight of the front half of the club head and not being easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be exemplified below and described in detail with accompanying drawings.

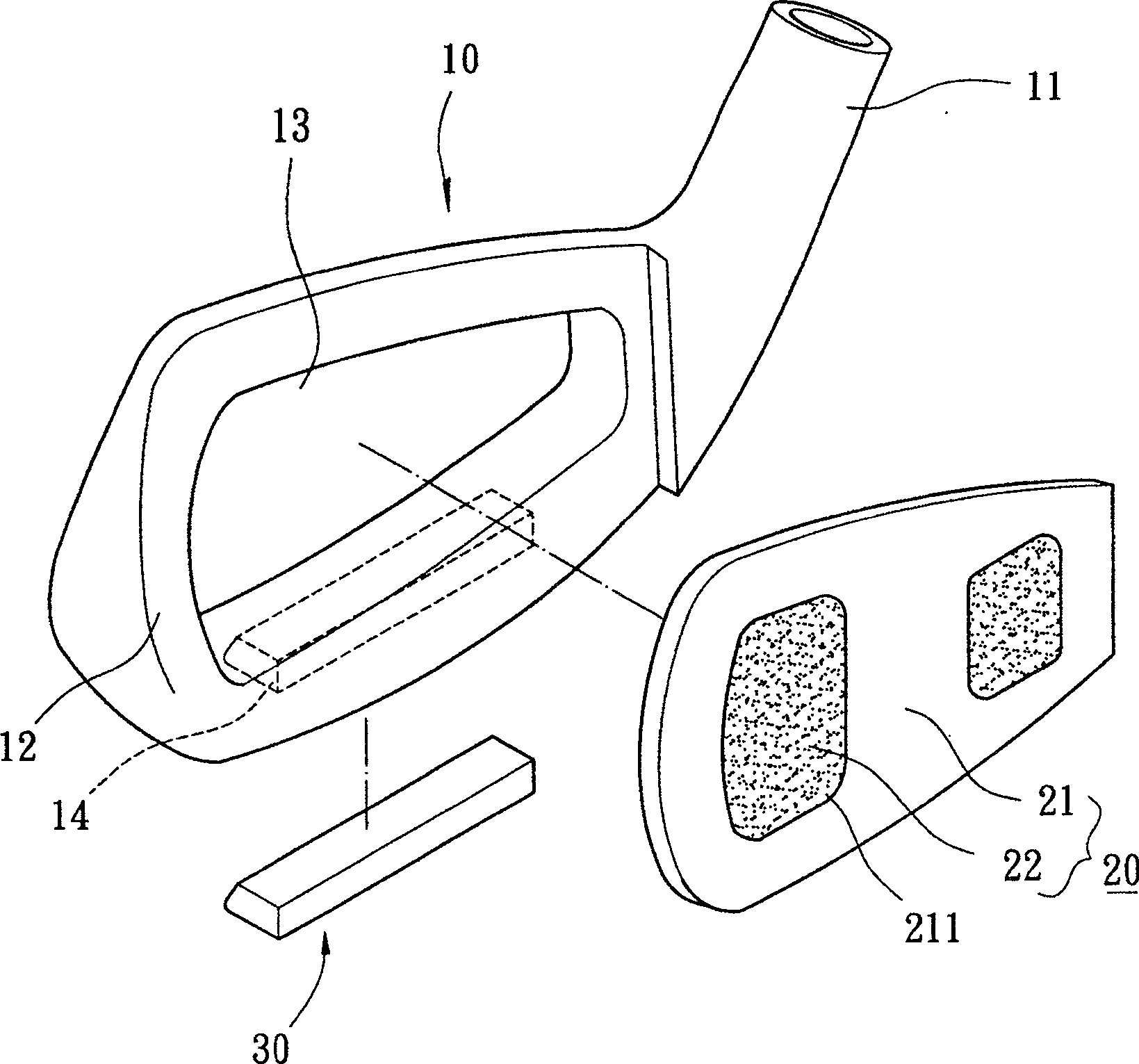

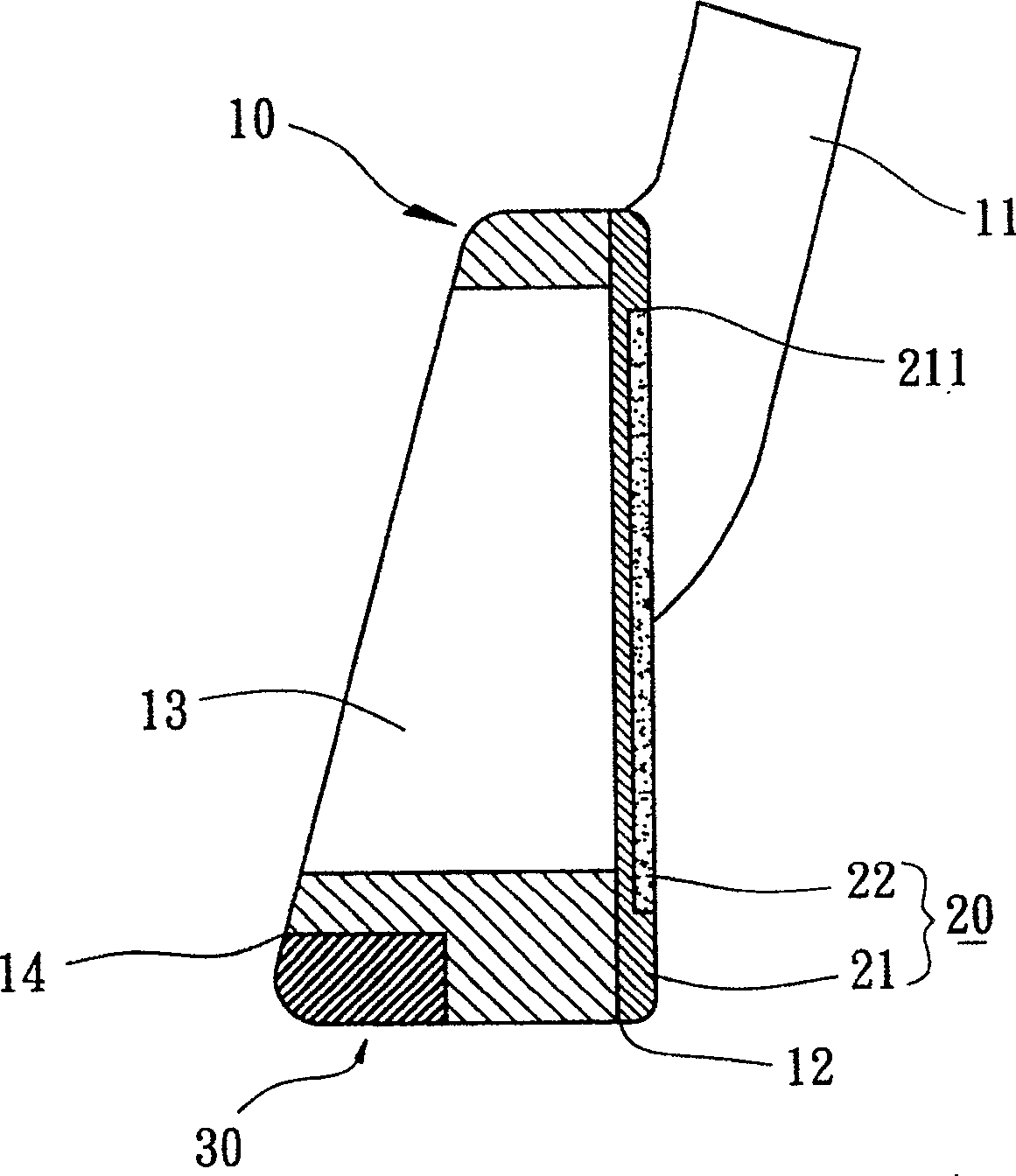

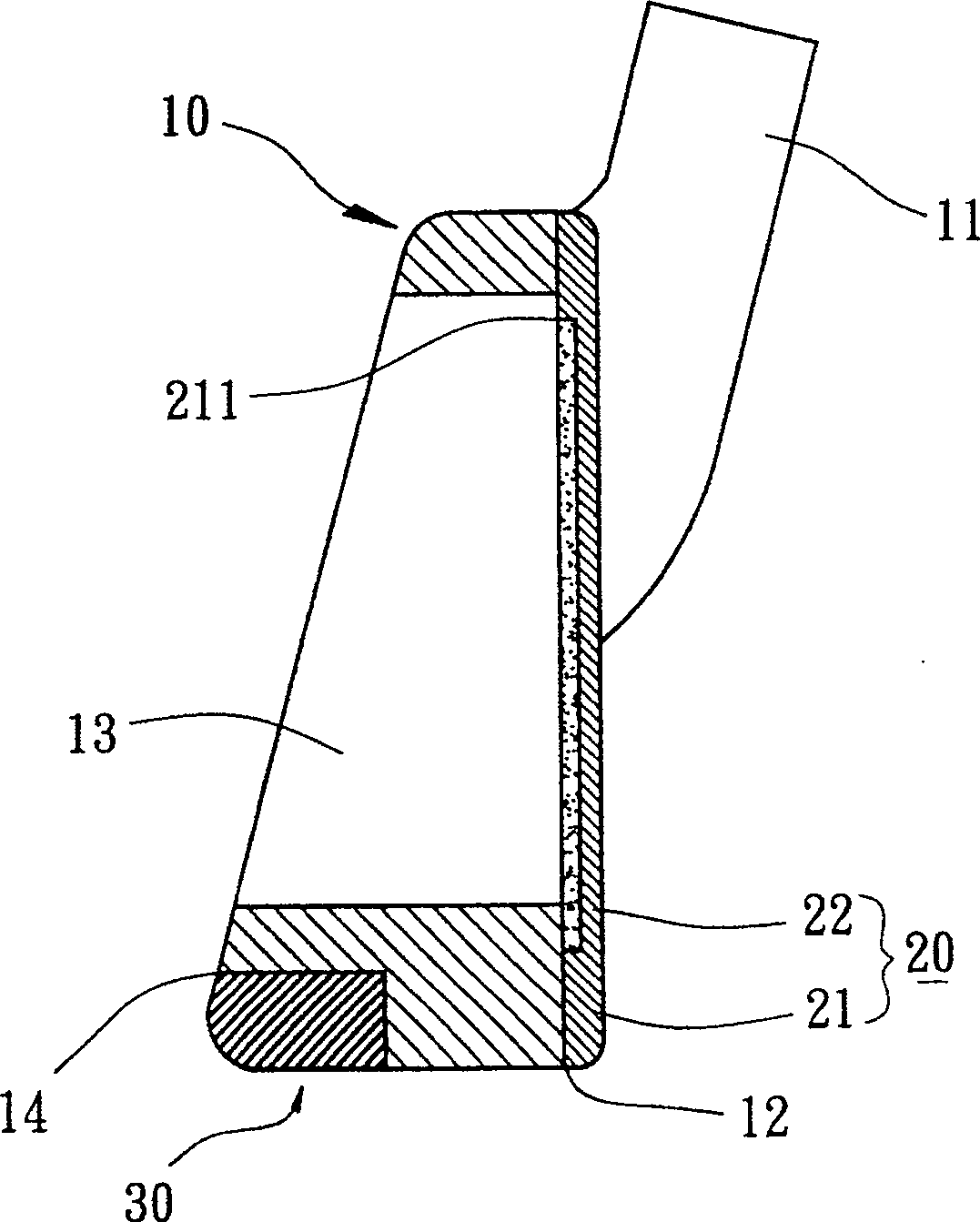

[0030] Please refer to figure 1 , 2 As shown, the structure of the golf club head with a low center of gravity in the first embodiment of the present invention essentially includes a body portion 10, a striking panel portion 20, and a counterweight portion 30, which together form a golf club head. The golf club head will be referred to below as Iron-type [iron] and wood-type [wood] club heads are taken as examples, but they can also be selected from conventional club heads such as utility or putter.

[0031] please refer again figure 1 , 2 As shown, the body portion 10 of the first embodiment of the present invention is an iron club head, which is preferably made of appropriate metal, alloy material or non-metallic material, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com