Air permenbility regulating machine

A technology of air permeability and adjustment machine, applied in electrical components, sensors, etc., can solve the problems of easy recovery, damage to goodwill, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

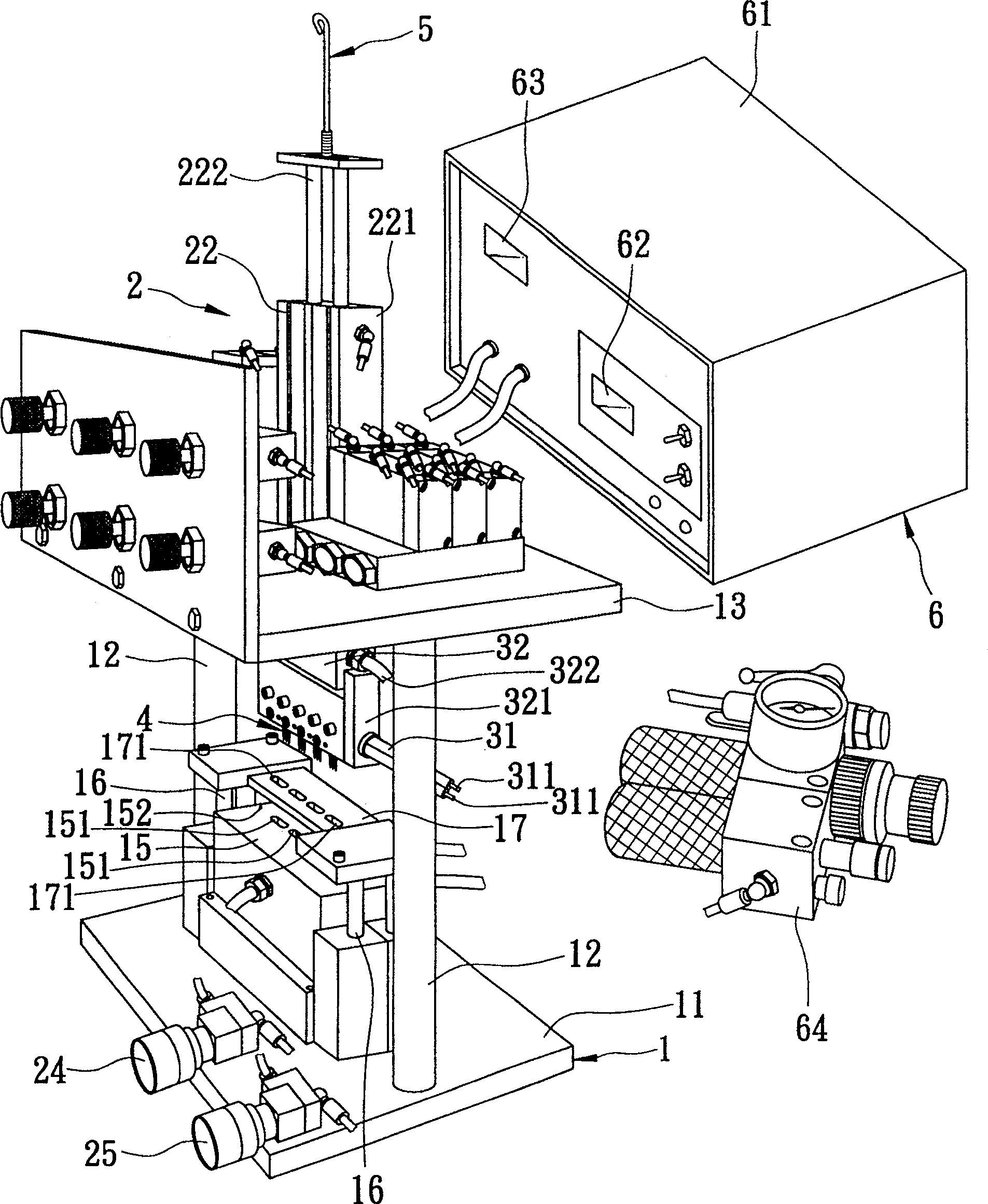

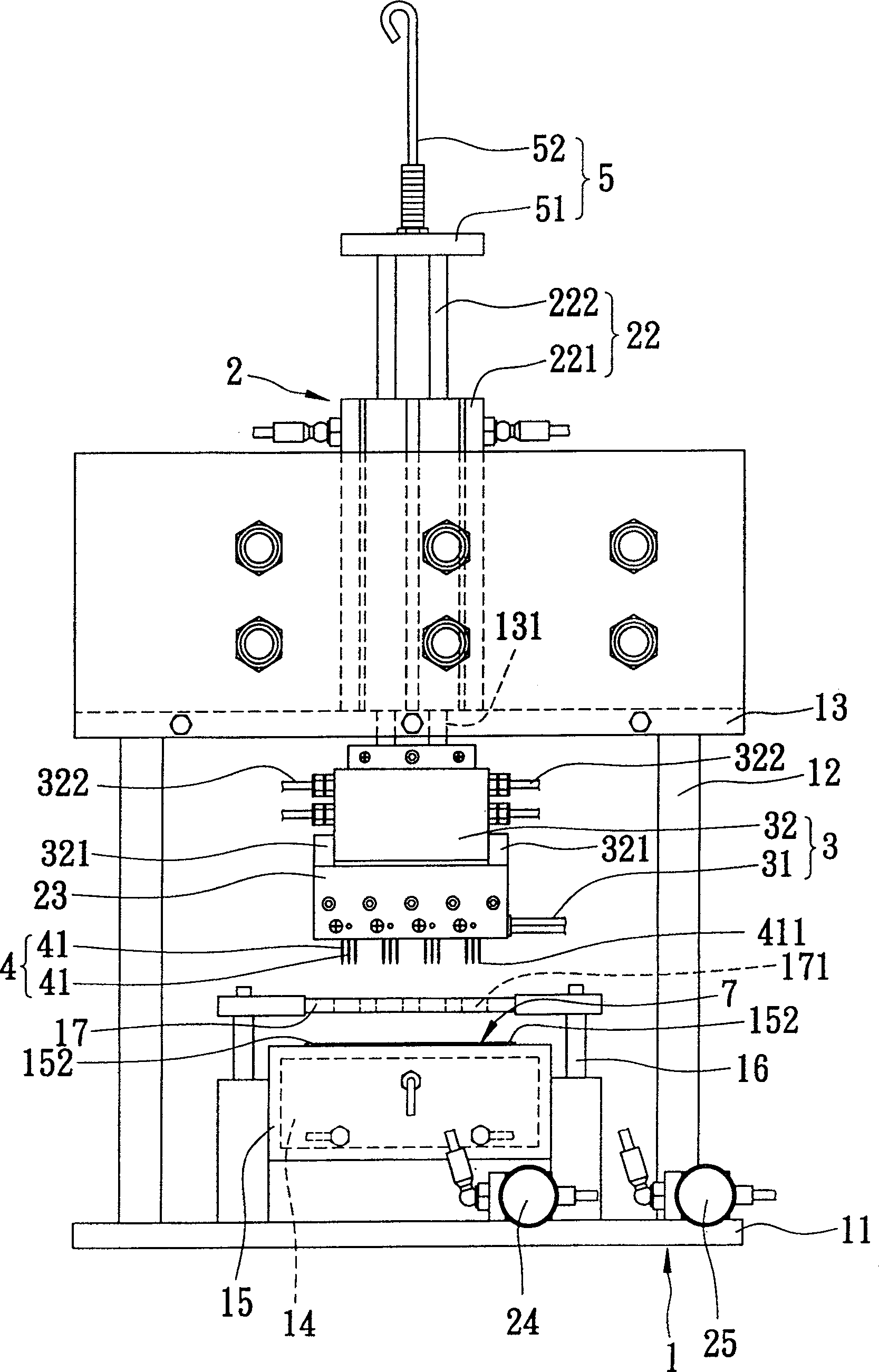

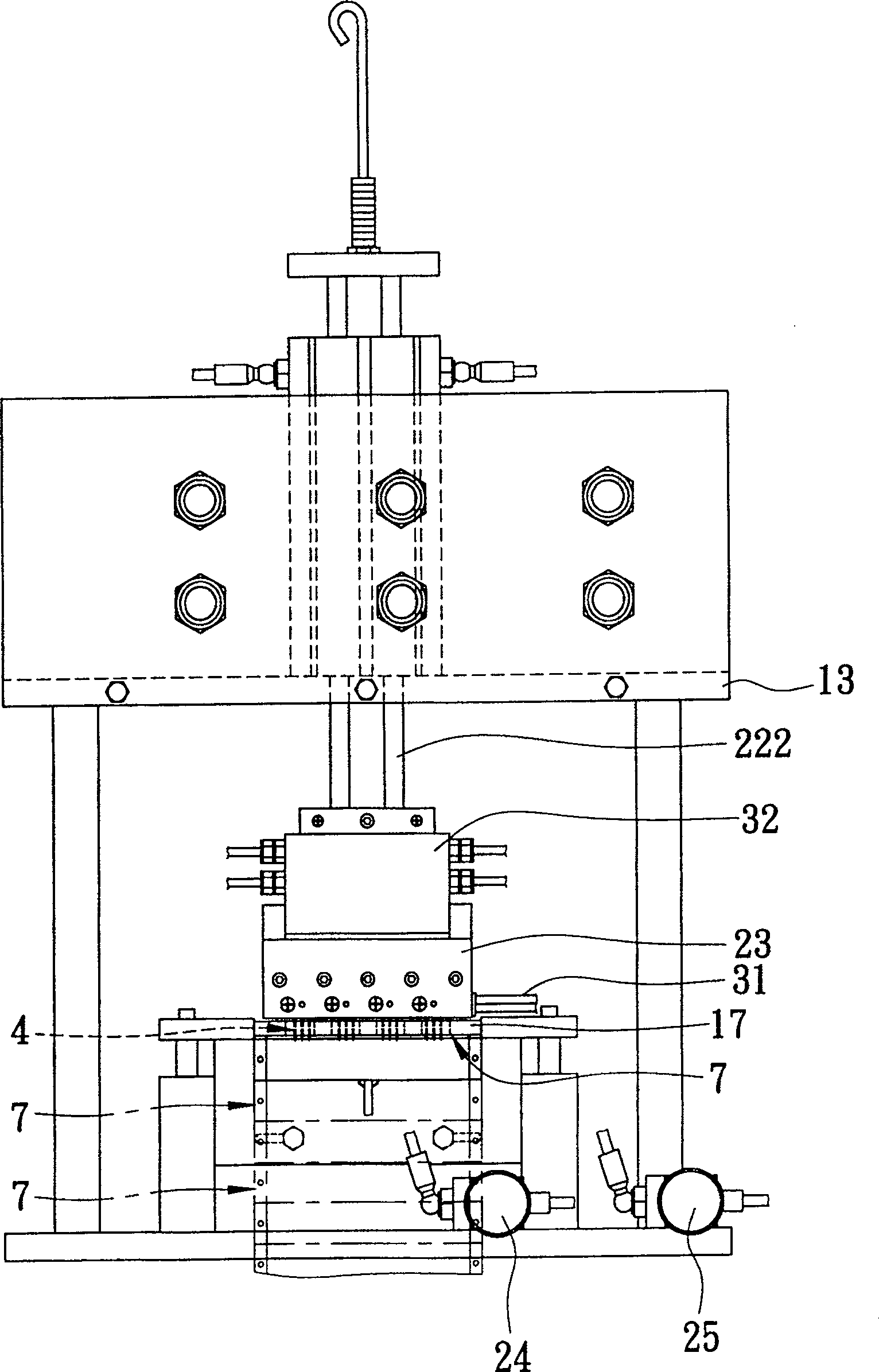

[0023] like figure 1 , figure 2 As shown, the present invention includes a base unit 1 , a drive unit 2 , a temperature control unit 3 , a piercing element 4 , a manual adjustment unit 5 and an instrument unit 6 .

[0024] like figure 1 , figure 2 , Figure 5 As shown, the base unit 1 has a bottom plate 11, several poles 12, a top plate 13 erected above the bottom plate 11 by several poles 12, a housing 15 placed on the bottom plate 11 and capable of defining an air pressure space 14, A platform 17 is supported by two press cylinders 16 and suspended above the casing 15 at intervals.

[0025] Holes 131 are formed on the top plate.

[0026] A plurality of through holes 151 communicating with the air pressure space 14 are formed through the top wall of the casing 15 , and positioning columns 152 are respectively arranged on two sides of the plurality of through holes 151 .

[0027] The platform 17 is provided with through holes 171 having the same number as the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com